A team of researchers at Tel Aviv University, Israel, has published a proof of concept study that could lead to cheaper metal 3D printers. The study examines the potential of localized microwave heating (LMH), that could be applied to produce rough, large scale structures at a faster throughput rate.

Localized microwave heating additive manufacturing

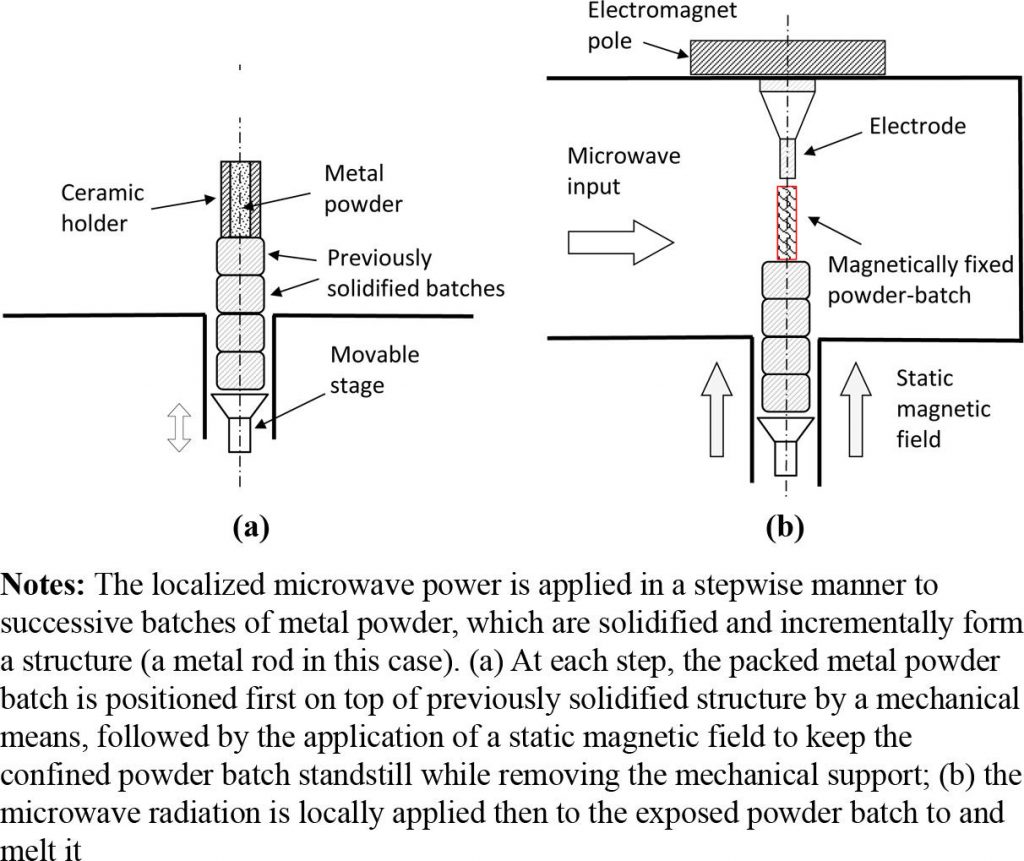

As described in the team’s Methods, “Unlike typical laser-based AM processes, using layer-by-layer techniques,” localized microwave heating additive manufacturing (LMH-AM) “uses small batches of metal powder as additive elements (namely,

voxels).”

Voxels are created by compacting metal powder into a spot on the build plate, or “interaction region.” Microwave irradiation is then applied, melting each voxel, which then solidifies upon cooling. To build a desired structure this process is repeated, merging metal voxel by voxel.

Magnetic fixation

The concept of LMH-AM was first proposed by Tel Aviv University in an article from 2015. Developing on the initial ideas discussed in this paper, the team’s most recent study experiments with the use of contact-less magnetic fixation of metal powder in the “interaction region” to simplify the process.

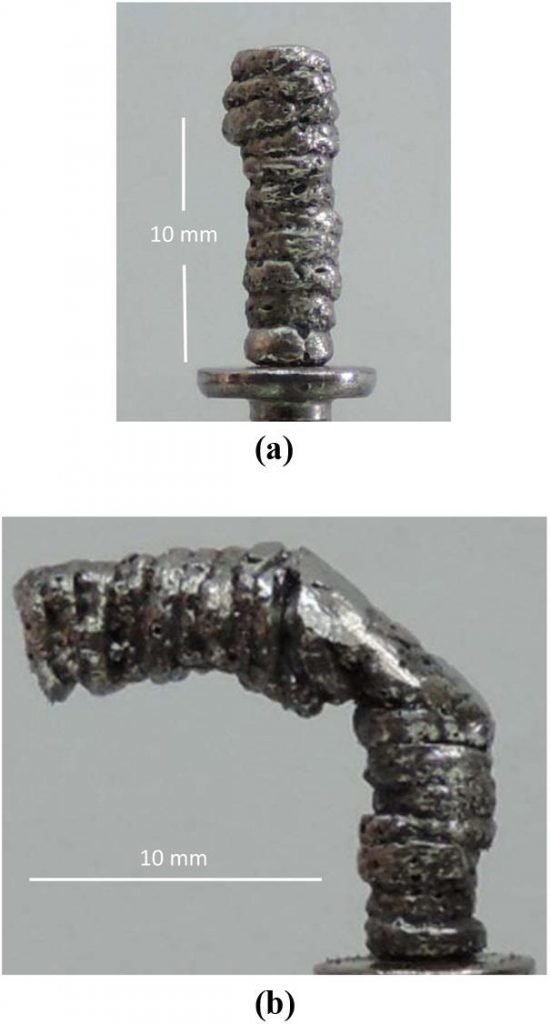

Results show that magnetically confined powders can be incrementally 3D printed to make small sample rods.

As stated in the study, “No mechanical support is needed during the microwave irradiation periods; hence, the LMH–AM process is significantly simplified.”

Encouraged by the findings, the team are now planning to study the LMH-AM process in an inert-gas environment, “which eliminates the plasma ejection and hence reduces the microwave power required to a level of approximately 100 W or less.”

Cheaper metal 3D printing

Other efforts seeking to lower the cost of metal 3D printing include the University of Sheffield’s ‘Diode Area Melting’ and the futureAM project from Fraunhofer Institutes in Germany.

Microwave 3D printing, meanwhile, is also under consideration for its potential to build structures on the moon.

The research discussed in this article, “Incremental solidification (toward 3D-printing) of magnetically-confined metal-powder by localized microwave heating,” is published online in COMPEL the International Journal for Computation and Mathematics in Electrical and Electronic Engineering. It is co-authored by Mihael Fugenfirov, Yehuda Meir, Amir Shelef, Yuri Nerovny, Eli Aharoni and Eli Jerby.

For more of the latest additive manufacturing news releases subscribe to the 3D Printing Industry newsletter, like us on Facebook and follow us on Twitter.

Sign up to 3D printing jobs for new opportunities in this field.

Featured image shows a diagram demonstrating a compacted voxel of metal powder. Image via COMPEL