Italian 3D printer manufacturer WASP has revealed a partnership with fitness equipment provider Technogym. The company is using the Delta WASP 4070 INDUSTRIAL 4.0 3D printer to help prototype and develop its new pieces of fitness equipment.

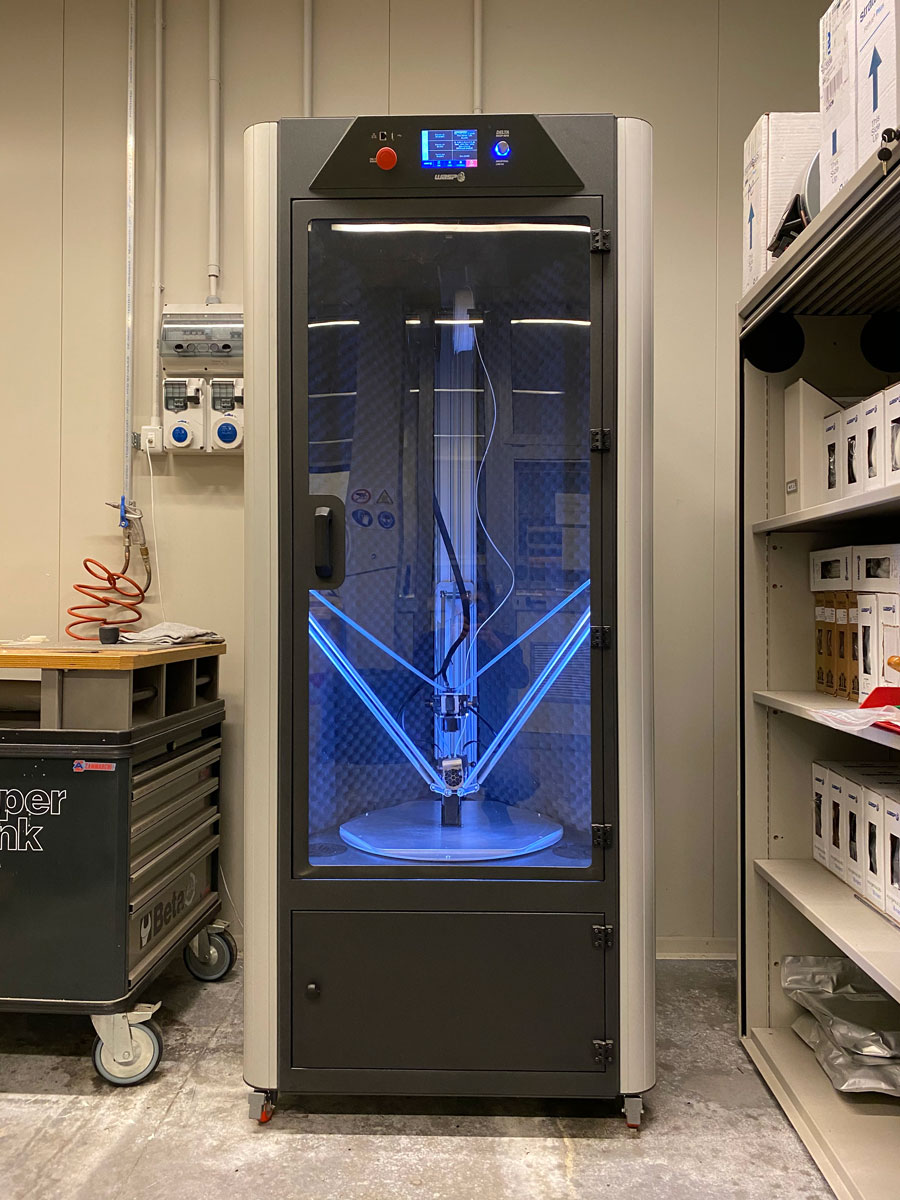

Technogym bought a 3D printer from WASP as it sought to lower its maintenance costs while enabling the production of large prototype components. As such, the WASP 3D printer has helped Technogym shorten its lead times, particularly with larger parts. “We chose the Delta WASP 4070 INDUSTRIAL 4.0 system for many reasons,one of the most important is certainly its large print volume feasibility,” Technogym explained in a statement.

“We also appreciate its printing speed and the much lower cost of support-materials, which allows us to buy more material spools and make more tests.”

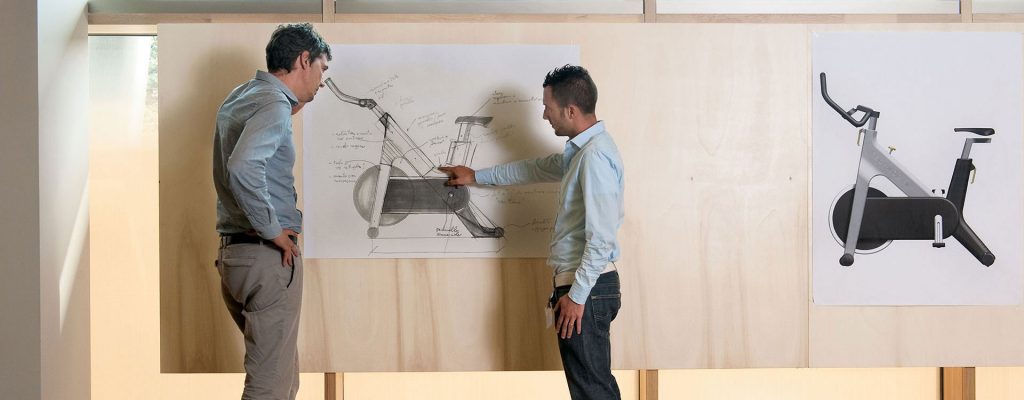

Prototyping with 3D printing in the fitness industry

Founded in 1983, Technogym is a manufacturer and provider of gym equipment for both home and fitness facilities. The company was also an exclusive supplier for the 2016 Summer Olympics in Rio.

To help develop its products, the Technogym Village headquarters, based in Cesena, Italy, is home to the T-Factory & T-Research and Development Department, where over 130 engineers and designers have produced 142 international patents and 93 trademarks for the company. The village is intended to be a “hotbed of ideas, where innovation, information and research are shared.”

As such, the company has placed its Delta WASP 4070 INDUSTRIAL 4.0 3D printer inside its T-Factory & T-Research and Development Department, the places where the company combines all its manufacturing process in one place to help nurture its product design. A number of the company’s products over the years have therefore been prototyped using the WASP 3D printer.

The Delta WASP 4070 INDUSTRIAL 4.0 is an FDM 3D printer built specifically for large part production, with a build volume of Ø 400 x h 700 mm. It also has a 150 mm/s maximum print speed. Technogym decided to purchase this 3D printer as the company believed it could help them visualize and accurately represent its product ideas, particularly in regards to shapes and purpose.

Previously Technogym had a smaller 3D printer, through which it was prototyping parts with ABS, however the company required a larger solution, in order to produce bigger components. As such, the Delta WASP 4070 INDUSTRIAL 4.0 3D printer has now become a key part of the company’s design and production workflow. Each month the company has been able to produce between 15 to 20 parts for its fitness equipment prototypes, measuring as much as 30 cm, while also reducing errors during the product development phase. The material compatibility of the Delta 3D printer has also allowed Technogym to prototype using PLA filament, a preferable choice for concept models as they don’t release toxic fumes during extrusion and deposition.

3D printing applications with WASP

WASP’s large range of 3D printers covers everything from small to large scale 3D printing in a number of materials, including ceramic. They have therefore been used in a number of interesting use cases over the years. Most recently, the company’s Delta WASP 2040 INDUSTRIAL 4.0 3D printer was integrated into a hybrid machine that combines additive manufacturing with juicing. Named Feel the Peel, it is a circular food system created by Carlo Ratti, an innovation and design firm.

Recently, WASP also engaged in a collaboration with Mario Cucinella Architects (MCA), an architectural firm based in Bologna. Together the partners are 3D printing a housing model for a sustainable global habitat, using WASPS construction 3D printing technology. This includes the Crane WASP 3D printer, a system with a print area of 6.60 m in diameter and a height of 3 meters.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image via the Technogym village. Photo via WASP.