Owens Corning, a leader in commercial and industrial construction industries, has developed the XSTRAND™ of composite 3D printer filaments to meet the demands of industrial, functional prototyping.

In our previous profile on Owens Corning’s glass-fiber reinforced polypropylene (GF30-PP) we saw how 3D printed prototypes could stand up to the elements in a case study from ski equipment manufacturer Rossignol.

In the second of Owens Corning’s XSTRAND™ range, we examine the profile of GF30-PA6, and the use of XSTRAND™ filaments to “make boats fly.”

GF30-PA6 filament is currently available from international distributors including Robo3D, IC3D, iMakr and ULTIMATE 3D Printing Store.

Nylon 6 – the workhorse polymer

Standard PA6, also known as Nylon 6, is produced at a rate over 4 million tons each year. Its primary consumer is the automotive industry that makes gears, bearings and a variety of under the hood parts from the material. It’s fiber form is also the material that makes toothbrush bristles and guitar strings.

Nylon 6 is tough, and highly resistant to abrasion. By adding glass fibers to the composition, Owens Corning maximizes these properties, achieving competitive strength.

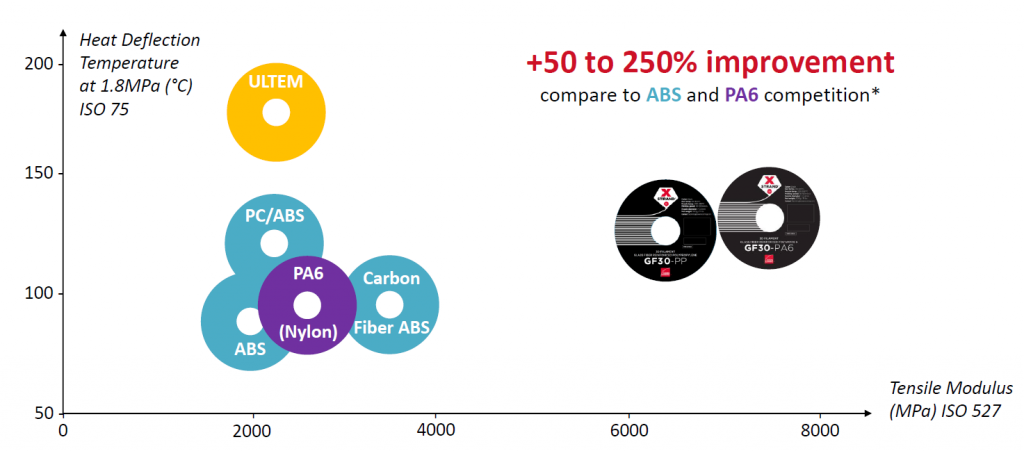

As the chart above shows, Owens Corning’s nylon/glass fiber composition is up to 250% stronger than standard ABS. Additionally, compared to standard ABS and neat PA6, GF30-PA6 is between 50% – 250% stronger and stiffer.

The glass fiber content also optimizes the PA6’s heat deflection temperature (at 1.8 MPa °C) to an average of 124 °C (254 °F), where neat PA6 typically deflects between 60 °C and 100 °C.

In addition to high heat deflection, Owens Corning’s GF30-PA6 has wide operational temperature range, between -20°C and 120°C, ensuring performance in extreme manufacturing environments.

As with all the GF30 XSTRAND range, GF30-PA6 has excellent layer adhesion, and reduces possible warping of neat material.

A side by side comparison between Owens Corning GF30-PA6 and GF-30-PP demonstrates PA6’s advantages when applied for strength.

| Mechanical Properties of GF30-PP | Mechanical Properties of GF30-PA6 |

| Tensile Modulus: 6 500 MPa | Tensile Modulus: 7 400 MPa |

| Tensile Strength (Yield): 60 MPa | Tensile Strength (Yield): 102 MPa |

| Elongation (Break): 1.6 % | Elongation (Break): 2.1 % |

| Flexural Modulus: 4 300 MPa | Flexural Modulus: 6 100 MPa |

| Flexural Strength (Yield): 83 MPa | Flexural Strength (Yield): 170 MPa |

| Flexural Strength (Break): 78 MPa | Flexural Strength (Break): 166 MPa |

| Heat Deflection temperature: 120 °C | Heat Deflection temperature: 124 °C |

At SEAir, a nautical manufacturer of foils for sailboats and motorboats, all products contain 3D printed components. In addition to 3D printed products, the company also uses the technology for large-scale robotic fiber laying as a coating for pre-fabricated parts.

Pushing 3D printing to the extreme, using GF-30 PP and GF-30 PA6.

Léo Talotte is a 3D printing engineer at SEAir. Talotte explains, “What’s good about XSTRAND™ is it gives us the ability to make parts that can’t be manufactured by any other technique. Compared to other materials, like ABS, there are no problems with resistance to UV or sea water.”

Used as functional prototype and end use parts, XSTRAND™ materials helps SEAir address aerodynamic problems, and bring new parts to market in record times. “These parts can be subjected to high mechanical loads, like the deflectors that are hit head-on by water at 40 knots,” adds Talotte,

“So all these 3D printed parts are not necessarily foils, but things that really help us make out boats fly.”

Upgrade your 3D printer production

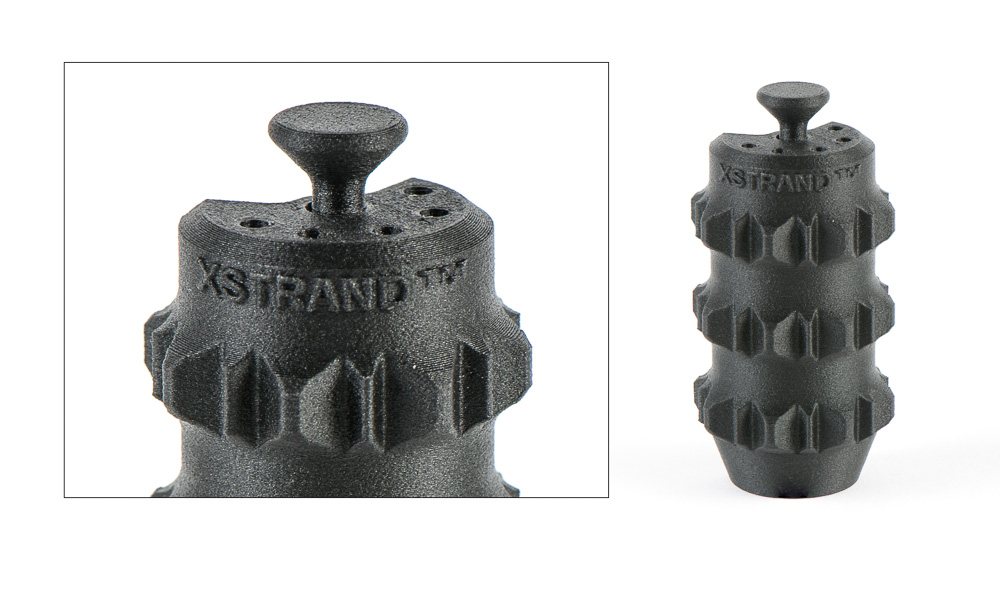

Owens Corning recommends 3D printing GF30-PA6 with a hardened steel extruder. A perforated build plate, HDPE sheet and appropriate adhesive will also ensure optimal performance.

GF-30 PA6 is available in both of the standard diameters for 3D printer feedstock – 1.75 and 2.85 mm, and can be bought as either a 500 g or a 2200 g spool.

For more information about the XSTRAND™ materials range you can also contact Owens Corning direct at the following email: [email protected].

Buy XSTRAND™ filaments online now from Robo3D, IC3D, iMakr and ULTIMATE 3D Printing Store. GF30-PP and GF30-PA6 filaments work great on Ultimaker, Zortrax, Raise3D and many more 3D printer brands.

Featured image shows SEAir, a customer of Owens Corning’s XSTRAND™ range, uses 3D printed part in all of its seafaring products. Photo by Arnaud Pilpré Studiomarlea/SEAir, DR.