Researchers at the Southwest Research Institute (SwRI) in San Antonio and The University of Texas at San Antonio (UTSA) are developing a 3D printed implant which can deliver a controlled medicine dosage over several weeks. The device could be used to help treat infections or provide ailment to patients suffering from things like arthritis, cancer or AIDS.

Project co-leader Albert Zwiener stated “The implant addresses a specific patient’s illness in addition to their medical history and other health issues. We inject this non-invasive device into the body to deliver medicine over a significant period of time.”

Delivering medicine with 3D printed implants

For a drug to be effective, patients must take a specific amount based on their condition. Because of this, patients who require frequent doses have to take daily medication or visit a doctor for treatment. With the SwRI/UTSA implant, a controlled, personalized dose of medicine can be automatically delivered to the patient over several weeks.

The project is supported by a $125,000 grant from the Connecting through Research Partnerships (Connect) program. The program encourages interaction between investigators with its main objectives to support inter-institutional projects and enable the development of proposals for peer-reviewed research funding.

The research team plans to create the device with a specialized 3D printer at UTSA that can print biodegradable materials. This makes removal of the implant unnecessary, as it will dissolve once treatment is complete. The implant is also engineered to trigger localized immunotherapy, which causes the body to attack cancerous tumors. While the implant is ideal for cancer treatment, it’s designed to work with any type of drug and could have a significant impact on a wide array of diseases and ailments.

Lyle Hood, project’s other co-leader spoke on the medical applications of the implant, stating

“If clinically translated, this would allow for doctors and pharmacists to print specific dosages to meet patients needs. In immunotherapy, most strategies employ systemic circulation through an IV line, much like chemotherapy. This can cause issues with immune reactions far away from the intended target. We hope that by delivering locally, we can keep acute effects constrained to the diseased region.”

Investing 3D printed medical implants

In recent years, 3D printing has become ubiquitous as a treatment for complex medical issues. Last year, medical device manufacturer, SI-BONE, announced FDA clearance for its 3D printed titanium medical implant. Medical device manufacturer, Stryker, recently funded a $9.29 million project to 3D print bone implants for cancer patients. And Texan medical device company, Osseus Fusion Systems, developed a collection of 3D printed spinal implants known as Aries.

Want to keep up with the latest 3D printing news? Then subscribe to the 3D Printing Industry newsletter. Also, follow us on Twitter, and like us on Facebook.

Looking for a change of pace or seeking new talent? Search and post 3D Printing Jobs for opportunities and new talent across engineering, marketing, sales and more.

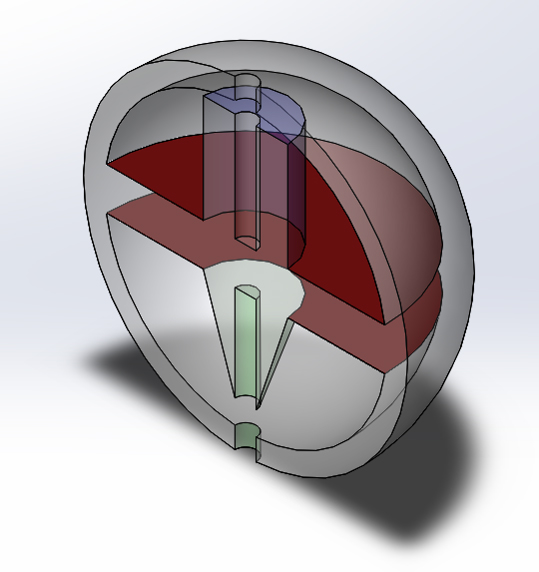

Featured image shows a concept of SwRI/UTSA implant device. Image via SwRI.