Researchers from the Swiss-based Bern University of Applied Sciences and ETH Zurich, have used 3D printing to modulate the perception of sweetness in low-sugar snacks.

Leveraging a dual extrusion-based technique, the team were able to fabricate a set of sucrose-based confectionery samples that tasted 30 percent sweeter than normal, without adding any extra sugars. In future, the Swiss research team aim to deploy their approach in the creation of solid foods with reduced fat, in an attempt to combat broader global health concerns such as obesity and diabetes.

Reducing our reliance on sweet snacks

The rapid rise of sugar consumption in the western world is widely-documented, and some studies claim that as many as 68 percent of global deaths are caused by sugar-induced Non-Communicable Diseases (NCD). What’s more, although many brands offer low or zero sugar alternative products, many consumers prefer the taste of the original, and continue to consume the more sugary version.

One method of helping people to combat their sweet tooth, is to reduce the calories in fatty snacks, but to balance the taste by artificially increasing the perception of sweetness via the snack’s ingredients. A number of previous researchers have already shown that varying the stimulation intensity of taste receptors in this way, can lead to enhanced taste perception.

In 2012 for instance, a Dutch research team found that sucrose levels could be reduced by 20 percent, without decreasing the sweetness intensity of the final product. The researchers showed that taste receptor cells are triggered by a sweet snack, which causes the cells to release neural signals, and their firing rate is governed by the sweetness intensity of the original stimulus.

As a result, people’s urges for a chocolate treat aren’t always caused by conscious desires, but instead, a change in sweetness perception can be triggered by the firing rate of these neural signals. Building on the ideas established during prior studies, the Swiss team sought to deploy a 3D printing-based approach, and produce customized ingredient concentrations within confectionary items.

The team hypothesized that introducing sugar gradients could also allow sensory perception to be manually adjusted, yielding tasty treats that are a moment on the lips, but not a lifetime on the hips.

3D printed foods with customized sensory sweetness

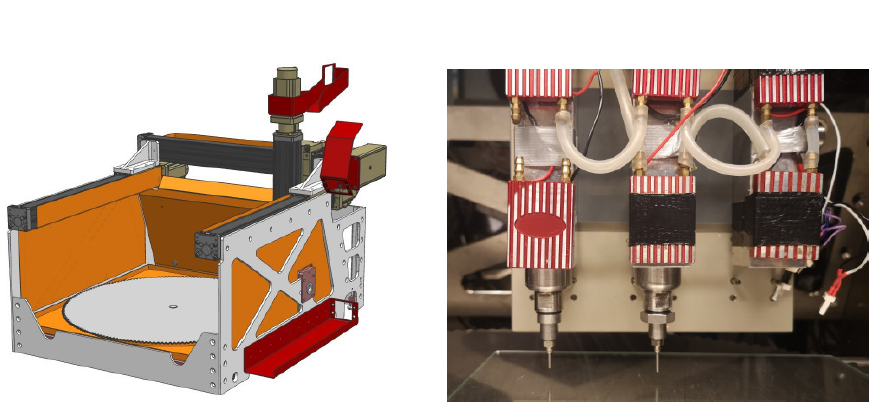

In order to test their theory, the researchers deployed a custom-built three-axis Cartesian printer armed with triple extruders, to 3D print two distinct types of cocoa-based samples. Both edibles measured 16x16x16 mm3 in size and featured different sucrose gradients, but one formed a layered shape, while the other was printed in a cube-in-cube format.

The researchers expected that once this confectionary was eaten, the sucrose would be released at different concentrations and at varying time points, leading to different ”pulses” of sweetness perception. To evaluate their theory, the team subsequently set up a ‘taste test,’ consisting of eight members of their team.

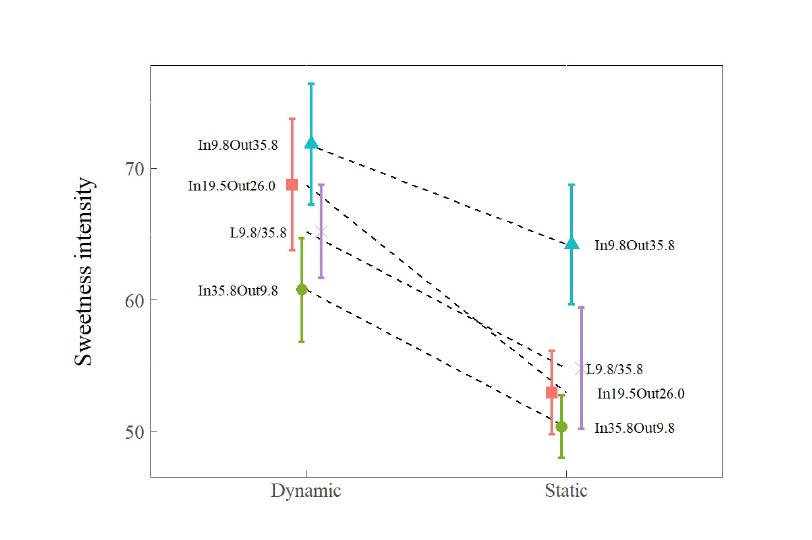

Each person sampled six rounds of chocolate, with plain crackers and water used to clear their pallets between rounds. Participants were then asked to rate the chocolate’s sweetness over time from 0-100, and at three different time points, to enable the scientists to measure the effectiveness of their gradients.

The results showed that although there was no significant difference observed between the samples at the first two time points, by the third, the team members had reported the gradient differences exactly.

A significant variation was also observed between the perception of the gradients in the two types of 3D printed sweet treats. The sample with high-sucrose shell but a low value core, was perceived to be 30 percent sweeter than the homogeneous sample, indicating that first impressions are still all-important in perception.

Such differences weren’t identified in previous liquid-based experiments though, hence the team intends to experiment with more complex designs in future. Also, as the layered sample proved more effective during initial testing, confectionery with a high number of layers could prove to be an effective way of modulating sweetness.

Either way, the researchers conceded that further optimization of their technique is required if they’re to establish their technique within a more commercial setting. Sadly, for now at least, that means 3D printing isn’t ready to take on the burden of solving the obesity crisis, and willpower and low-sugar alternatives will have to do.

Optimizing fabricated foods

Although many people would associate 3D printing with prototyping and production runs rather than culinary treats, an increasing number of companies and researchers are using the technology for just that.

Scientists from the Singapore University of Technology and Design have developed a new method of fabricating milk-based desserts, that prevents them from being spoiled at room temperature. Instead of changing the printing process to achieve this, the team adjusted the rheological makeup of powdered milk, to make a new edible range of inks.

Elsewhere, numerous companies have commercialized extrusion-based technologies to create vegan-friendly meat substitutes. Redefine Meat launched a 3D printed steak earlier this year, while Legendary Vish brought an additive manufactured salmon to market.

The researchers’ findings are detailed in their paper titled “Modulation of sweetness perception in confectionary applications.” The research was co-authored by Tobias Kistler, Angela Pridal, Charlotte Bourcet and Christoph Denkel, and published in the Food Quality and Preference journal.

Nominations for the 2020 3D Printing Industry Awards are still open, let us know who is leading the industry now.

The fourth edition of the 3D Printing Industry Awards Trophy Design Competition is now underway. Enter your design for the chance to win a CraftBot Flow 3D printer.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the triple extruder system that the researchers used to 3D print their chocolates. Photo via the Food Quality and Preference journal.