Researchers from the Swinburne University of Technology have developed a novel 3D printed polymer-liquid hybrid Radio Frequency Identification (RFID) antenna.

Created using a low-cost FDM fabrication technique, the team’s new detection device features microfluidic channels, that allow its polarization to be changed using different ionic fluids. The scientists have specifically designed their tag to be utilized within embedded systems, potentially making it ideal for biological or chemical monitoring applications.

The biosensing capabilities of RFID tags

RFID devices use radio waves to identify physical objects through solid surfaces, and a typical setup includes a tag, reader device and some software. The technology is used extensively within supply chain and logistics, but they are increasingly being applied to monitor the health of human beings too.

Traditionally, RFID tags have been categorized as either passive, active, or semi-active depending on their power source, but 3D printing has brought fresh approaches to sensor production. In particular, the development of a series of new passive devices has rapidly made wearable biosensors more viable than before.

Scientists from the University of California, have developed an ingestible RFID capsule, while the Italian Scuola Superiore has produced a tag that’s able to monitor temperature inside the body. Building on these ideas, the Swinburne team theorized that a liquid-hybrid antenna would provide enhanced, more customizable sensing capabilities.

Fabricating the microfluidic RFID device

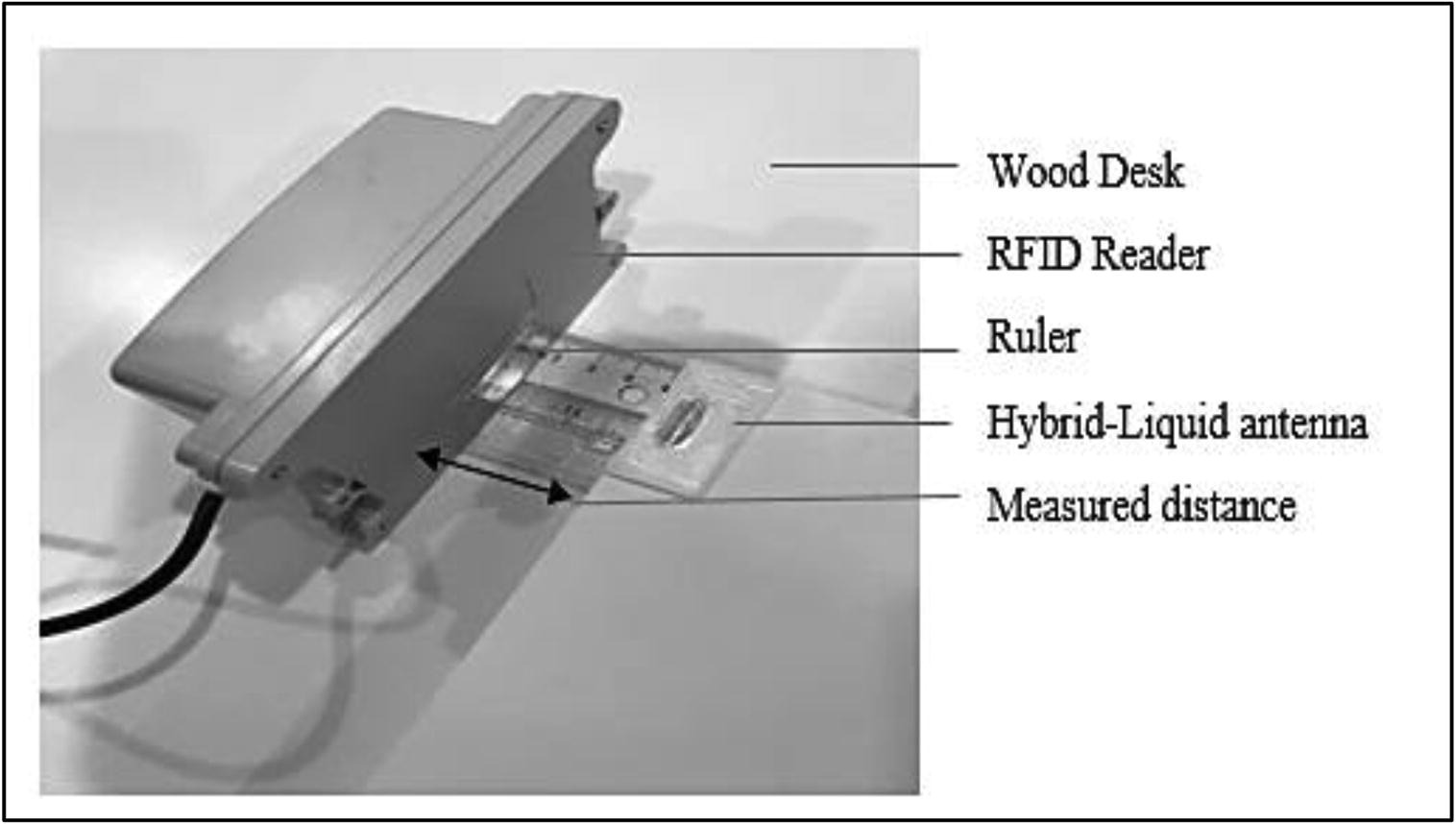

To create their novel device, the scientists procured a standard passive RFID tag and modified it, so that it only used its chip and resonant circuit. A new liquid antenna was then designed using Solidworks CAD software to feature microfluidic channels, and summarily 3D printed using a Tractus3D T850 system.

In theory, filling the antenna’s channels with an ionic liquid would allow its sensitivity to be adjusted, depending on its end-use application. In order to test this hypothesis, the team connected the modified aerial with a chip and its resonant circuit, and evaluated its performance in comparison to an unmodified RFID tag.

During testing, the radiation distance between the scientists’ device and its reader was measured every ten minutes, while the latter was moved further and further away. Interestingly, the team’s tag proved to be capable of reading metal surfaces from a greater distance than with polymers, although results were inconsistent.

Flooding the device’s channels with peppermint oil was also found to create a ‘buffer zone,’ which eventually enabled the researchers to change its polarization. Overall, the novel sensor was able to measure from a maximum distance of 900mm away, and it proved capable of operating at a low power level of −17dBm.

Given that the system’s channels has allowed the team to change its phase response by 90 degrees, they considered their approach to be a success. In future, the scientists believe that the tailorable nature of their device could allow bespoke tags to be developed, that address the specific needs of their target application.

Making advances in additive biosensors

3D printing enables the production of parts with integrated microfluidic channels, and researchers are increasingly using this technology to create ‘lab-on-a-chip devices’ with biosensing capabilities.

Scientists from the CCDC Soldier Center have developed 3D printed sensors that could be used to monitor the physical wellbeing of soldiers on the frontline. The spherical devices are characterized by microfluidic channels, that also enable the detection of textile and atmospheric deterioration.

Elsewhere, a team from Sungkyunkwan University have 3D printed wearable medical biosensors for personalized monitoring applications. The flexible, lightweight devices have demonstrated the ability to monitor the body strain signals of patients in real-time.

Similarly, researchers from Clarkson University have developed a custom bio-ink that’s enabled them to create skin-compatible 3D printed biosensors. The novel devices allow users to prevent any potential overexposure to the sun’s UV rays.

The researchers’ findings are detailed in their paper titled “Design of a 3D-printable UHF RFID hybrid liquid antenna for biosensing applications.” The study was co-authored by Metin Pekgor, Mostafa Nikzad, Reza Arablouei and Syed Masood.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Swinburne team’s 3D printed hybrid RFID tag. Image via the Materials Today: Proceedings journal.