The architecture sector has combined functionality and aesthetics once more with the 3D printing of an innovative new wall using additive manufacturing technology developed by Voxeljet.

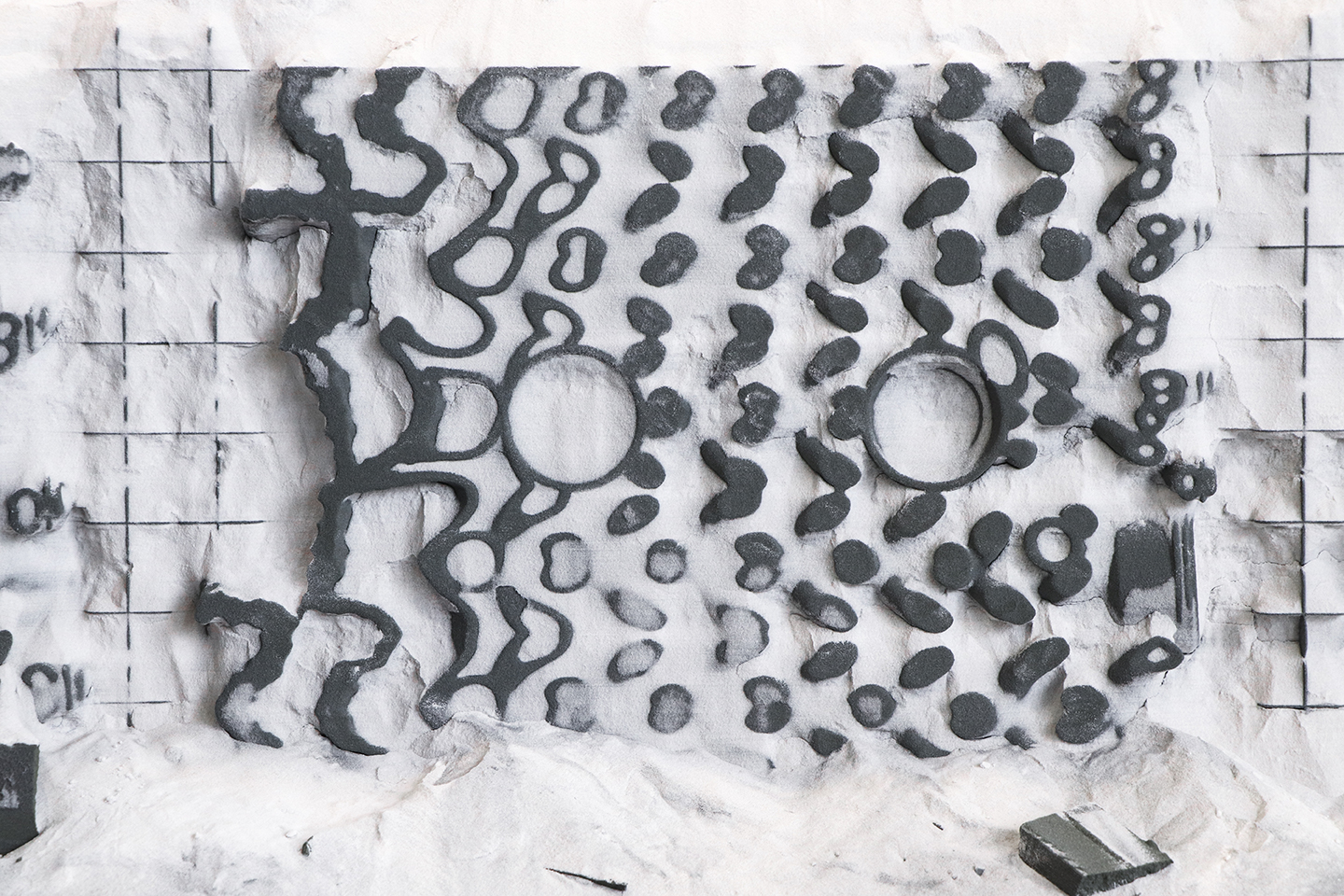

Designed by Swedish architects David Andreen and Ana Goidea, the Meristem Wall is a 1.25 x 2.1 x 0.7m structure that integrates several functional features designed to demonstrate the power of additive manufacturing. This includes piping for electrical wiring and water flow, a complex ventilation network, and a computationally optimized surface structure that enables the wall to serve as an urban wildlife habitat.

Ana Goidea explains, “The ability to create complex and unique forms and geometries with technologies such as 3D printing opens up a whole new realm of aesthetical, efficient, and incredibly functional architecture. And that’s what we want to show with the Meristem Wall.“

A myriad of 3D printed functional features

It’s no secret that the design freedom offered by 3D printing enables the technology to create a limitless number of abstract geometries. In architecture, this translates to the possibility of producing building envelopes that passively harness local micro-climates by storing heat and humidity, driving airflows through convection, and other mechanisms.

So what makes the Meristem Wall so special? As well as being entirely capable of supporting its own weight (and more), the structure integrates electricity and light fixtures, water pipes made of PEX tubing, windows, and even a built-in rainwater run-off system.

Additionally, the wall features air filtration functionality, an interior fabric surface, and a comprehensive distributed ventilation system that controls the heat storage and internal moisture levels – all without any moving parts.

Two years in the making

Ana and David have spent the past two years developing the Meristem Wall. Much of the design work was conducted at Lund University’s bioDigital matter lab, and relies on a series of generative design algorithms developed by the architects themselves.

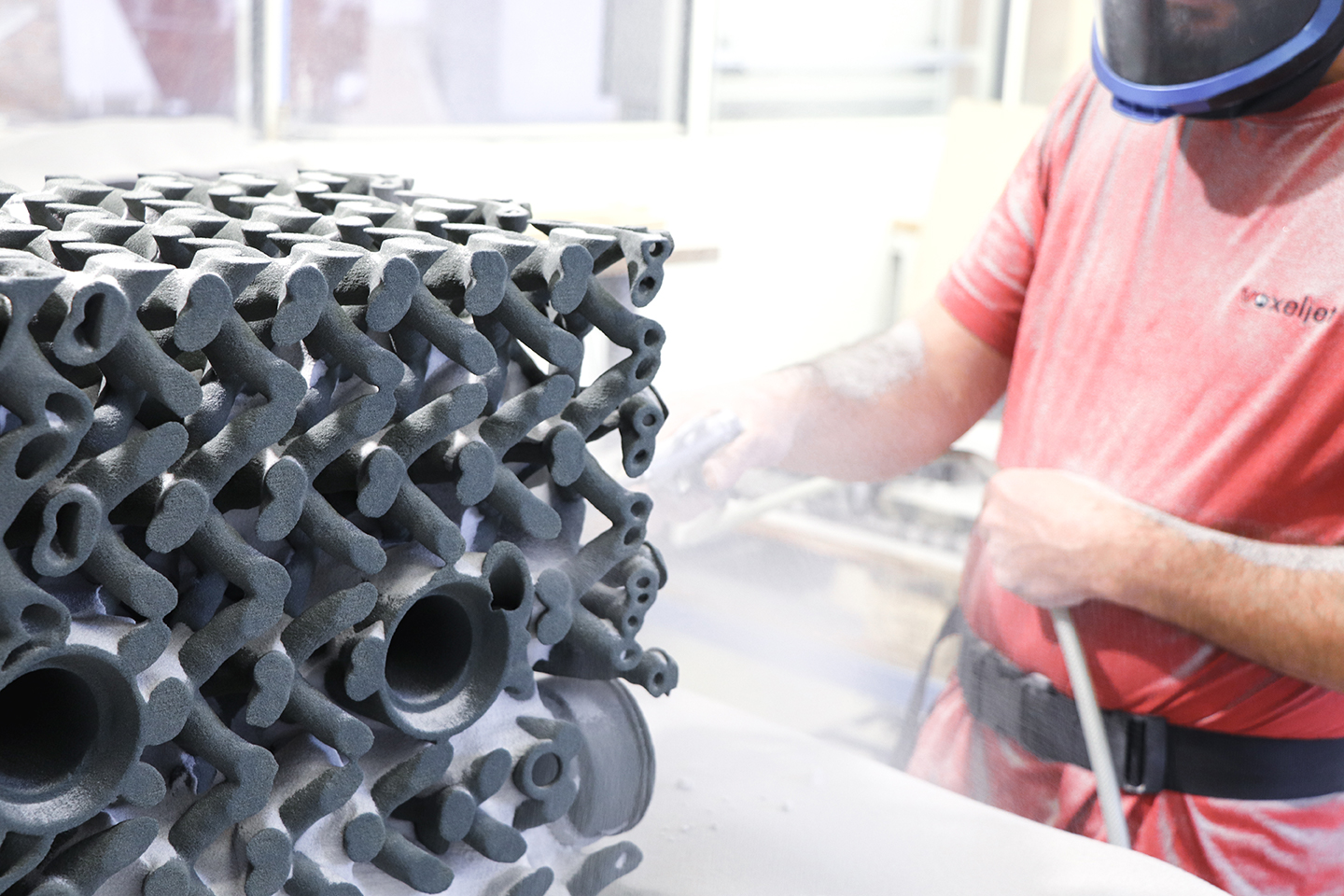

Since the large dimensions of the wall were far too big for most additive manufacturing systems, the duo eventually settled on Voxeljet’s VX4000 3D printer, which offers a build volume of 4 x 2 x 1m. The large-format binder jet system is compatible with sand and well suited to 3D printing mold and core applications.

Tobias Gruen, product manager at Voxeljet, adds, “The main challenge for us was the high degree of complexity with the fine inner structures and tubes. Since we print in a sand bed, after the printing process is completed, we have to remove all the unprinted sand from the bonded structures. So, when we print structures with cavities, that means they are always filled with unprinted sand.”

To derisk the post-processing workflow, the wall was decomposed and 3D printed in 21 individual pieces, which made unpacking the parts much easier. The architects then employed the help of Sandhelden, an Augsburg-based sand processing firm, to help infiltrate the parts with epoxy resin for added strength.

Laurens Faure, CEO at Sandhelden, said, “It took us approximately three days to fully cover the wall with epoxy resin but in the end, we can say that we are very happy with the end result. While concrete 3D printing is ideal for classic facades, as soon as slightly more complex geometries or details come into play, concrete printing doesn’t pose as a good match anymore. This is exactly where we see the strength of binder jetting.”

Once printed, the parts were transported to Venice and assembled into the final Meristem Wall structure. Ana and David displayed their project at the Venice Architecture Biennale 2021 until November 21.

The combination of aesthetics and functionality is a running theme within the construction 3D printing sector. Earlier this year, construction 3D printing company Branch Technology completed a similar project with the 3D printing of a building facade for a financial institution in Chattanooga, Tennessee. Pedestrians passing by the Tennessee Valley Federal Credit Union’s (TVFCU) new Southside branch will see the TVFCU’s signature wave branding incorporated into the design of the building itself, and it directs customers towards the entrance.

More recently, Zaha Hadid Architects (ZHA) and furniture manufacturer Tecno also showcased their new ‘ALIS pod’ office concept in the Venice Giardini, featuring a custom plant-based 3D printed floor. Developed by Amsterdam-based architectural 3D printing firm Aectual, the pod’s distinct base is a carbon-neutral terrazzo flooring.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the 3D printed Meristem Wall. Photo via David Andreen and Ana Goidea.