Mathematicians from New York University (NYU) have used 3D printed wings and color-coded computer simulation to determine the ideal wing shape for fast flapping flight.

In a study published in the Proceedings of the Royal Society, a team from NYU’s Courant Institute of Mathematical Sciences aimed to improve the mechanics concerned with the motion of objects (kinematics). Thus, the researchers explored fixed-wing flight by altering the parameters of additively manufactured wings. Leif Ristroph, an assistant professor at the Courant Institute of Mathematical Sciences and the paper’s senior author said:

“We can simulate biological evolution in the lab by generating a population of wings of different shapes, have them compete to achieve some desired objective, in this case, speed, and then have the best wings ‘breed’ to make related shapes that do even better.”

“Such a method could be used in related optimization problems, such as tuning kinematics or flexibility for flapping propulsion, and for flow–structure interactions.”

Winging it with 3D printing

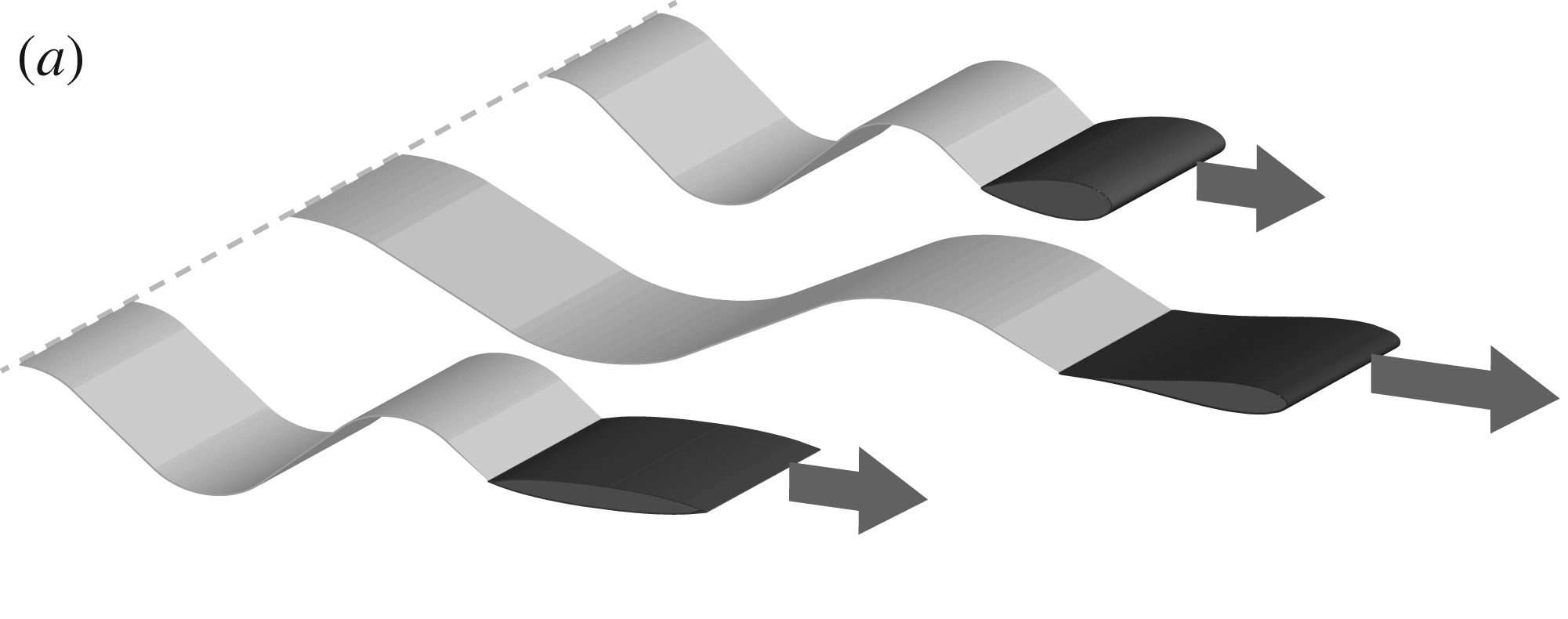

Within the NYU Applied Math Lab, the researchers 3D printed wings that could be flapped mechanically, for a series of comparative tests. The channels of these wings were then filled with dyes, i.e., fluorescein and rhodamine, for flow visualization inside a water tunnel. After recording the movement of each 3D printed wing, its shape was iteratively improved using an evolutionary algorithm.

Such experiments began in 2015 to demonstrate a scheme that modifies the cross-sectional shape of the speed of wings or hydrofoils – a lifting surface that operates in water) in forward heaving-and-plunging flight.

“This ‘survival of the fastest’ process automatically discovers a quickest teardrop-shaped wing that most effectively manipulates the flows to generate thrust,” explained Professor Ristroph.

“Because we explored a large variety of shapes in our study, we were also able to identify exactly what aspects of the shape were most responsible for the strong performance of the fastest wings.”

A new wave

The NYU team found that the fastest wing shape has a razor-thin aerodynamic surface (trailing edge). This enables strong vortices or “swirling flows” during flapping.

“We view the work as a case study and proof-of-concept for a much broader class of complex engineering problems, especially those that involve objects in flows, such as streamlining the shape to minimize drag on a structure,” added Ristroph.

“We think this could be used, for example, to optimize the shape of a structure for harvesting the energy in water waves.”

“Improving the propulsion speed of a heaving wing through artificial evolution of shape” is co-authored by Sophie Ramananarivo, Thomas Mitchel, and Leif Ristroph.

![An experiment revealing ideal airfoil shapes for flapping flight, with the flows generated at the front part of the wing [red] and the rear [green] visualized using fluorescent dyes. Image via NYU.](https://3dprintingindustry.com/wp-content/uploads/2019/01/image.img_.480.high_.jpg)

NYU researchers are studying additive manufacturing in many areas in addition to alternative energy scavenging processes. Last year, Scientists and surgeons at NYU School of Medicine and NYU College of Dentistry, shared research on 3D printed implants that dissolve as a bone heals.

Following this, engineers from NYU Tandon and NYU Abu Dhabi in the United Arab Emirates (UAE), began developing 3D printed QR codes in the prevention of counterfeiting and intellectual property (IP) theft.

Which academic/research team warrant a 3D Printing Industry Award? Make your choice now, while nominations are open.

Also, for the latest 3D printing news, subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Looking for a fresh start this year? Visit 3D Printing Jobs to commence your career in additive manufacturing.

Featured image shows a 3D printed wing filled with fluorescent dyes flapping in a water tunnel. Clip via NYU.