A group of four masters students from the Bartlett School of Architecture, UCL, have designed and 3D printed a novel multi-material building panel for architectural applications.

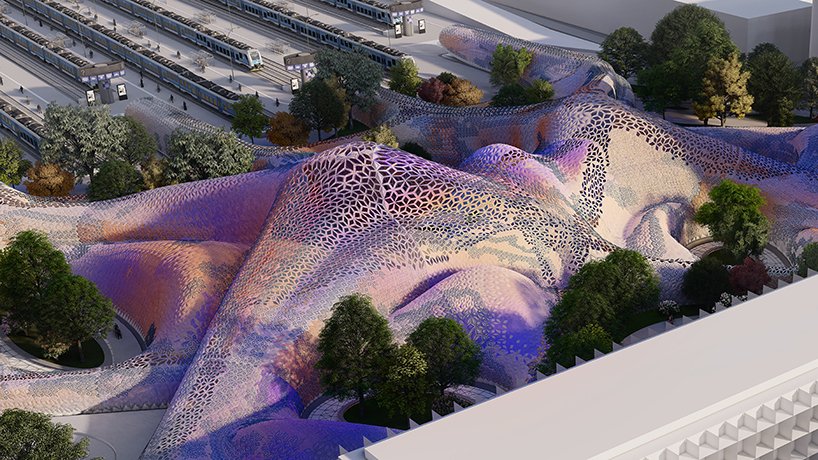

Dubbed Metaplas, the project utilizes combinations of both rigid and flexible recyclable polymers to create a geometric architectural folding panel via 3D printing. To demonstrate how the structure could be used out in the real world, the students applied their design as a potential facade for Euston Station in London – a sci-fi-esque roof canopy featuring a fluid form and a plethora of colors.

The Metaplas project

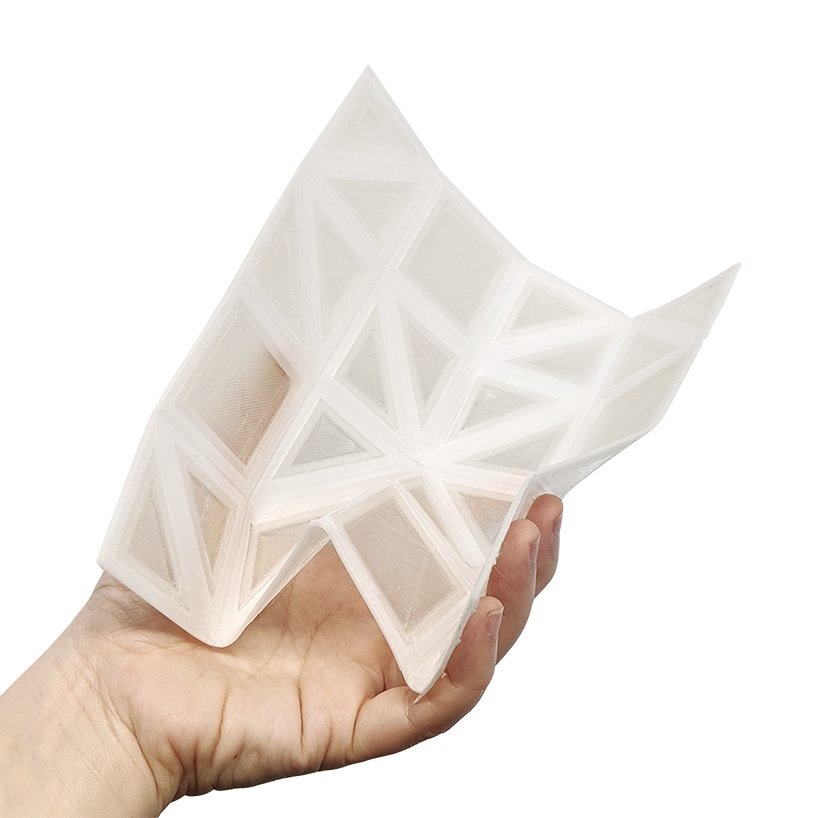

The Metaplas project was commenced with the aim of designing a multi-material structure that combines progressive design, structural feasibility, and 3D printability. Starting off with an extensive period of materials research, the Bartlett team identified PLA and TPU as suitable polymers for the individual foldable multi-material panels. The modular design was then 3D printed in a flat form but could be folded into a 3D geometry due to its integrated folding patterns, much like a piece of origami paper.

The folding patterns themselves were generated using a custom computational tool that relies on structural analysis. As such, sections of a large structure that are expected to bear the most load would see an adaptive increase in fold density, while other sections may be sparse in folds. The individual panels are designed to be securable to each other with a clip-lock system and cables, ensuring streamlined assembly, maintenance, replaceability.

Taking it a step further, the students also studied the integration of thermochromic polymers into their panel design. These are materials that are temperature-sensitive, so they change color when exposed to heat. In the context of the architectural panels, this could help with lighting control during day and night cycles, directing pedestrians to nearby exits while increasing the level of natural light that makes it indoors.

Utilizing a decentralized 3D printing network

During the conceptualization phase, the students also placed a major focus on using a decentralized digital manufacturing network. Although the panels were never mass-produced or even used outside of the design project, the consideration acted as a feasibility study for potential applications in the future.

For example, for the Euston Station demonstration, the students identified and mapped several materials recycling and 3D printing facilities in a defined radius from the train station. If the rendered project were to actually go through to completion, this decentralized 3D printing network would be used to fabricate all of the individual panels in the structure. This would have the effect of boosting the local economy while also promoting a more ecological and ethical approach to production, as transportation distances and costs would be greatly reduced.

The Bartlett team comprises Betty Chavez Angeles, Prapatsorn Lertluechachai, Wisnu Hardiansyah, and Marwah Osama.

The bridging of functionality and aesthetics is a key advantage of additive manufacturing in the construction space. Earlier this month, Dutch 3D printing service Royal3D 3D printed a modular and flexible workspace pavilion within the Rotterdam Makers District. Created on behalf of the Port of Rotterdam Authority, the R-IGLO was made using recycled PET waste. The polymer pod is currently a pilot project but may feature in the Port Authority’s Real Estate department portfolio in the future.

Elsewhere, construction firm Branch Technology recently 3D printed its first building facade for a financial institution in Chattanooga, Tennessee. The building features the Tennessee Valley Federal Credit Union’s signature wave branding incorporated into the design itself, and was fabricated using the company’s proprietary robotic arm-based Cellular Fabrication (C-Fab) 3D printing technology.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a close-up view of a 3D printed architectural structure. Image via UCL.