American professional racing team Team Penske has revealed how its partnership with 3D printing company Stratasys has been implemented on the track.

Team Penske, who race in both the NASCAR and IndyCar championships, signed a deal with Stratasys earlier this year in February. Since then, the 3D printer manufacturer has been busy redesigning parts for the racing team with the intention of improving performance.

Every split second counts

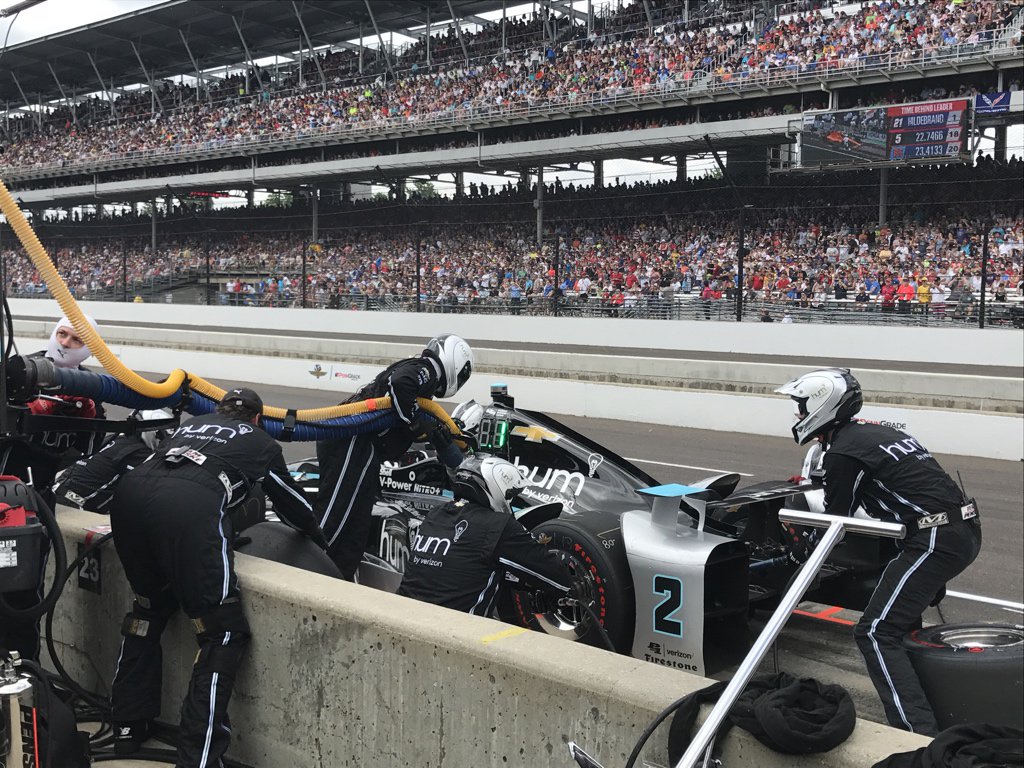

Speaking to WXYZ news Stratasys’ Director of marketing, Jim Vurpillat, explains how Team Penske is benefiting from the partnership. The IndyCar team approached Stratasys with the idea of reducing the weight of the fuel line that is used during pit stops. Notorious for requiring rapid refuelling and tire changes, the pit crew are now equipped with a 3D printed carbon fiber fuel line handle which improves on the former all-metal design.

By doing so, Team Penske’s pit crew teams can now refuel the cars with greater speed and ease, as Vurpillat reports, the refuellers believe they have “shaved a couple tenths (of a second) off.” In addition, the 3D printed tool retains the strength of the original part despite reducing weight considerably.

Gaining an edge

Currently, Team Penske has 3 drivers in the top five of the Indycar 2017 season standings with driver Helio Castroneves only 8 points behind rival Scott Dixon. However, with 9 races left in the 2017 season Team Penske definitely has time to close the gap and Stratasys will hope small improvements like the fuel line handle will make a difference.

Similarly across the pond, British Formula One team McLaren also signed a partnership agreement with Stratasys earlier this year. As a result, the team revealed how it brought a 3D printer trackside during this year’s Formula One season.

In the future of IndyCar, Vurpillat explains how Stratasys is keen “to get more and more 3D-printed parts on the car itself.” Already thinking towards next year and the subsequent car design changes, Vurpillat says,

We’ve got a couple areas we’re working on, nothing we can talk about yet, but I think you’ll see more and more as we move forward.

As a prototyping tool, we’ve seen how motorsport teams have implemented 3D printing in the development of cars. Following the conclusion of the 2016/17 Formula One season, 3D Printing Industry explored the use of the technology in light of imminent car design changes.

For all the latest 3D printing news, subscribe to the most widely read newsletter in the 3D printing industry, follow us on twitter and like us on Facebook.

Featured image shows Will Power and Helio Castroneves in practice. Photo via Team Penske.