Leading 3D printer manufacturer Stratasys (NASDAQ:SSYS) has officially announced the formation of two subsidiaries.

Vulcan Labs, Inc. is a spin-off designed to advance the adoption of Powder-Bed Fusion (PBF) based technology throughout the metal engineering industry.

Evolve Additive Solutions on the other hand emerges from nearly 10 years in stealth mode as promoter and developer of the Selective Toner Electrophotographic Process (STEP). A new 3D printing technology STEP is reportedly up to “50 times faster than the next fastest AM plastics technology.”

Observant readers will remember Evolve Additive from our article in September 2017.

Ilan Levin, CEO of Stratasys, comments, “To provide Vulcan with the best path to achieve its vision, we decided to form a new and independent entity, with Stratasys as an equity stakeholder,”

“We are delighted to continue supporting this team and look forward to collaborating with them and their partners to achieve this vision.”

In relation to Evolve Additive, Levin adds, “As an independent company, Evolve will best be able to focus on the advancement of the technology, provide the entrepreneurial environment and management equity incentives suitable for early stage efforts and drive the customer relationships and partnerships to foster further development and initial market adoption,”

“As an equity stakeholder, we look forward to collaborating with Evolve and supporting this initiative to help make it a success.”

Customers take control

Vulcan Labs was bought by Stratasys in 2014 as specialty service bureau Harvest Technologies. At the time, Harvest Technologies offered a host of rapid prototyping and manufacturing services including CAD modeling, metal casting, CNC machining, and 3D printing (FDM, SLS, SLA).

Under the direction of Stratasys the company has since honed its expertise as Vulcan Labs, and currently focuses on preparing PBF technology to meet metal production requirements.

“Our team will bring a unique perspective to solving many of the issues from an end-user perspective,” comments David K. Leigh, CEO of Vulcan Labs, Inc. “We’re looking forward to delivering new solutions for customers to take control of their applications, while having the tools in place to manage their own quality.”

Managing powder-bed fusion

Vulcan currently has five mission objectives which it will complete in collaboration with industry partners. In the first of these objectives, the company seeks to optimize PBF build chambers and develop multi-laser strategies.

In the second, taking spatter principles into account, Vulcan will develop a closed loop melt pool quality control system.

Third, harnessing Cloud based services and IoT, the team will perform detailed data logging procedures for system integration to the factory floor.

Fourth, Vulcan aims to automate the powder handling process and provide in-situ materials characterization.

And finally, it aims to enhance auto-calibaration and setup of PBF machines to ensure optimal usage.

Vulcan’s objectives neatly align with Stratasys’ $25 million investment in UK based metal powder production specialist LPW, and efforts made by the Stratasys Direct Manufacturing service.

Levin adds, “Vulcan’s best-in-class team has both the experience and technical know-how necessary to bring PBF into real-world production – a vision perfectly aligned and complementary to our other activities in this space.”

STEP by STEP up to high-volume 3D printing

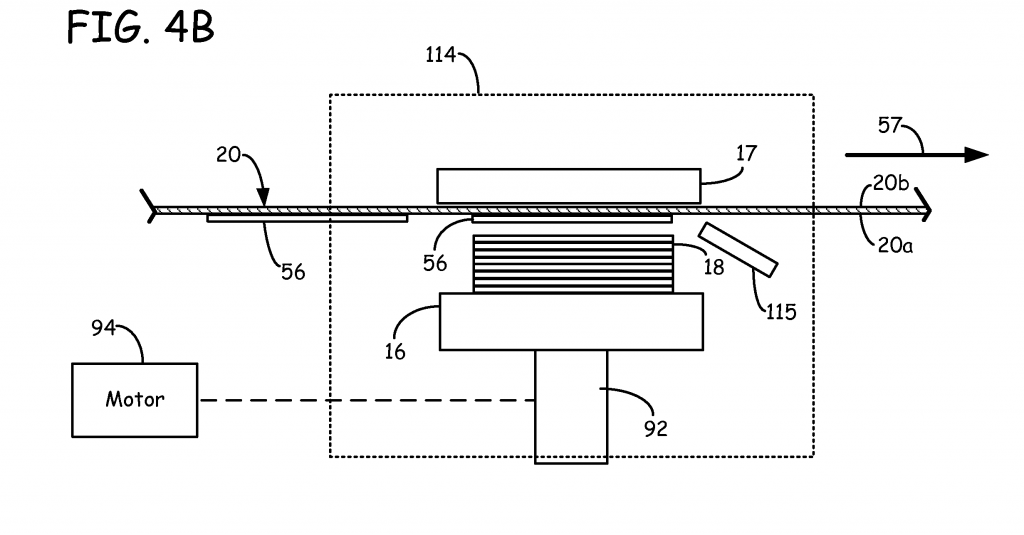

STEP 3D printing technology has been in development at Evolve Additive Solutions since 2009. Then called electrophotography-based additive manufacturing, STEP is a rapid 3D printing process based on technology commonly found in photocopiers and laser printers.

A patent for the process was assigned to Evolve in December 2016, and details a powder based polymer 3D printing technique that uses light reactive material, heat and/or pressure to build an object layer by layer.

Advantages of the STEP process include:

- “Cost per part and surface quality comparable to traditional manufacturing”

- “Isotropic properties on par with injection molding”

- Full color and multimaterial 3D printing

STEP co-inventor and Evolve CEO Steve Chillscyzn comments “We believe the STEP Technology is uniquely positioned to bridge the gap in the market not yet addressed by additive or traditional manufacturing technologies,”

“It is the first-of-its-kind technology offering an additive method for mass production. It’s designed to deliver the benefits of additive, while handling high-volume production.”

Evolve are seeking alpha stage purchases of STEP systems in the automotive, consumer goods and aerospace industries. The first beta STEP systems are to be expected from Evolve over the next 12 months.

Want to be the first with the latest 3D printing news? Subscribe to the 3D Printing Industry newsletter, follow us on Twitter and like us on Facebook.

Voting for the 2018 3D Printing Industry Awards is still open. Make your selections or submit a wildcard vote now before closing in May.

3D Printing Jobs is now live too. Post a job or seek a new role now.

Featured image show full color Stratasys 3D printed samples. Photo via COBRT/PADT