3D printer manufacturer Stratasys has announced a slew of new developments for its additive manufacturing business.

The mass launch includes two new industrial FDM 3D printers, the F190CR and F370CR, which are designed for high-strength composite parts. Stratasys is also launching a total of 16 new 3D printing materials across its FDM, P3, and SAF technologies. As a bonus, the firm has also introduced GrabCAD Print software for the Stratasys Origin One and Origin One Dental 3D printers.

The F190CR and F370CR

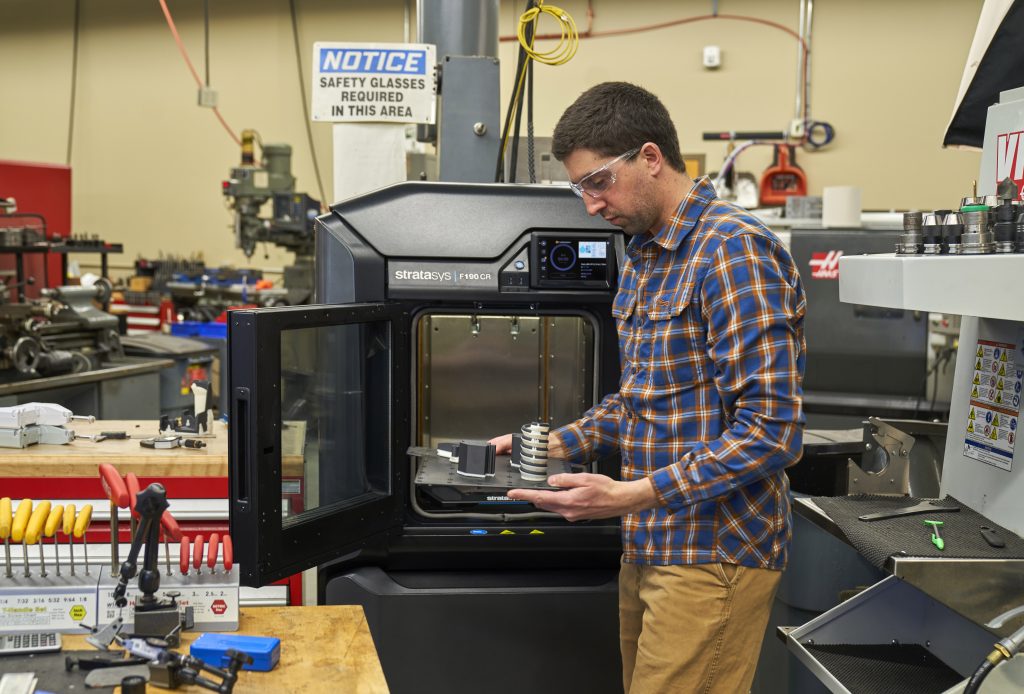

The latest additions to Stratasys’ F123 product line are the F190CR and F370CR. Both composite FDM systems are designed to print with high-stiffness, high-strength engineering materials, enabling applications such as jigs, fixtures, workholding tools, and other high-performance end-use parts.

The F190CR is the smaller of the two, sporting a build volume of 305 x 254 x 305mm. It features two filament spool bays (one model, one support) and is capable of processing Stratasys’ ABS-M30, ASA, FDM TPU 92A, ABS-CF10, and FDM Nylon-CF10 materials.

On the other hand, the larger F370CR boasts a build volume of 355 x 254 x 355. The system comes equipped with four filament spool bays (two models, two supports) with auto material changeover functionality, allowing for multi-material prints with PC-ABS, Diran 410MF07, ABS-ESD7, and more.

Both 3D printers feature reusable build trays, built-in cameras for remote monitoring, and 7” full-color touchscreens. They also include integrated GrabCAD Print software and enterprise application connectivity via the MTConnect standard.

Dave Thompson, VP of Worldwide Engineering and Customer Care – Contractor Equipment Division for Graco, said, “Over the years we have grown our fleet of Stratasys printers and expanded our applications beyond prototyping to tooling, fixtures and grippers for our robots. The new Stratasys F370CR printer will allow us to bring our AM applications to a new level, extend the life of our tools and even provide for a better surface finish.”

16 new 3D printing materials

Stratasys has also announced the launch of 16 new materials across three of its additive manufacturing technologies: FDM (6), P3 (8), and SAF (2).

The FDM list includes Arkema/Kimya PEKK-SC, a PEKK based on Arkema’s KEPSTAN; VICTREX AM 200, a semi-crystalline LMPAEK; Covestro PA6/66 GF20 FR, a flame-resistant glass fiber composite; Kimya PC FR, a flame-resistant polycarbonate; HIPS high-impact polystyrene; and Stratasys’ own FDM Nylon-CF10, a new carbon fiber composite for use with the F190CR and F370CR.

Customers using the P3-based Origin One 3D printer also have access to open materials through the annual Open Material License (OML) introduced by Stratasys last year. The OML program has just been bolstered with eight new resins suitable for molding, casting, high-temperature, ceramic, ESD, and elastic applications. They can be purchased directly from the materials developers: Covestro, Evonik, Arkema, Forward AM, Mechnano, Tethon 3D, Liqcreate, and polySpectra.

Stratasys has also announced two new materials for use with the H350 3D printer, which operates on the firm’s SAF technology. PP is defined by its ductility and chemical resistance, while PA12 is the most widely-used polymer powder in industrial 3D printing.

GrabCAD Print for the Origin One

Finally, Stratasys has introduced GrabCAD Print for the Origin One and Origin One Dental 3D printers. As a piece of the GrabCAD Additive Manufacturing Platform, GrabCAD Print is a comprehensive slicing software designed to make print preparation as easy as possible.

Now compatible with the Origin systems, resin customers will be able to leverage the software’s automatic support generation tools, labeling functionality, native CAD file support, printer status monitoring, and build scheduling functionality.

Ronen Lebi, Vice President, Head of Production (P3) for Stratasys, said, “After being acquired by Stratasys, customers told us that the ability to use GrabCAD Print should be a top development priority. Today we are happy to announce that we’re able to bring the productivity and simplified workflow of GrabCAD Print to that rapidly growing community of Origin One users.”

To complement the GrabCAD integration, Stratasys will also begin offering Origin One Local, a new on-premise printer configuration, and the Origin One ProAero air extractor system for use in enclosed spaces. GrabCAD Print for Origin One, Origin One Local, and Origin One ProAero are all expected to launch in H2 2022.

Technical specifications and pricing

Below are the technical specifications for the F190CR and F370CR 3D printers. Visit the Stratasys store page to request a quote.

| F190CR | F370CR | |

| Build volume | 305 x 254 x 305mm | 355 x 254 x 355mm |

| Filament bays | Two | Four |

| Machine size | 1626 x 864 x 711mm | 1626 x 864 x 711mm |

| Weight | 227kg | 227kg |

| Heated chamber | Yes | Yes |

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Stratasys F190CR 3D printer. Photo via Stratasys.