3D printing has the potential to usher in a new era of point-of-care, personalized medication. With custom meds, pharmacists and physicians could provide patients with a dosage tailor made to their unique physiology, delivering more effective treatment in a record amount of time.

Though this vision as yet is far from achieving certification, researchers around the world are in the process of laying the necessary groundwork to bring 3D printers to local surgeries and clinics.

At St. John’s University in Queens, NY, Professor Abu T. Serajuddin and his team have been preparing a list of “pharmaceutically acceptable” polymers for fast acting drug delivery.

3D printed Haldol

In the most recent study from Professor Serajuddin and associates Nayan Solanki, Md Tahsin, and Ankita Shah, three commercially available and widely used polymers have been tested. Haloperidol, the an antipsychotic drug for commonly known as Haldol, is used as an example drug.

Treating schizophrenia and other conditions

Haloperidol is the most commonly used typical antipsychotic drug in the world. It is prescribed as a treatment for a number of conditions including schizophrenia, drug induced psychosis, hyperactivity and severe alcohol withdrawal symptoms.

In treating such volatile conditions, haloperidol works fast, demonstrating effects on average within thirty to sixty minutes. When dissolved orally, a typical tablet leaves 60-70% of its drug content. As such, any drugs made to deliver the drug must demonstrate the same productivity.

How does 3D printing affect the drug?

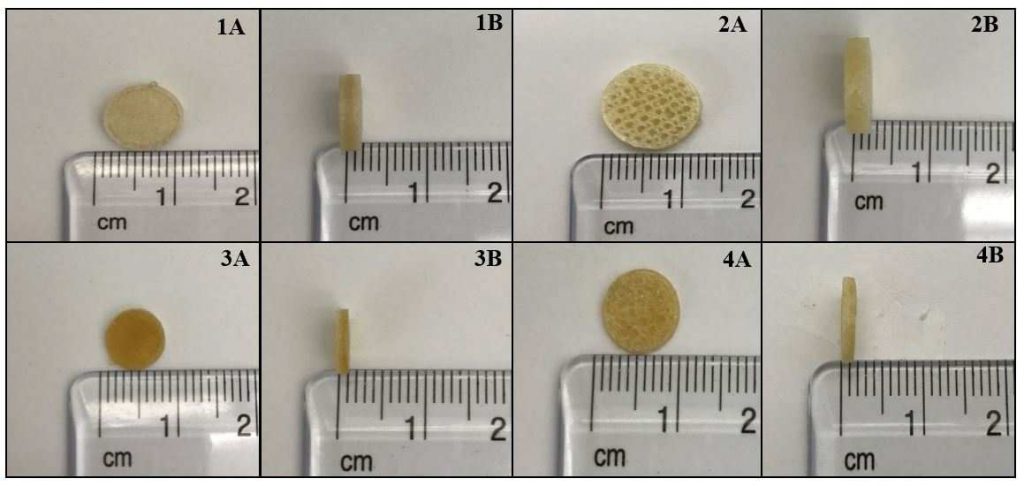

In the research at St. John’s different concentrations of haloperidol are combined with polymers and hot melted to make 3D printer filament. The combinations are 3D printed as pills of a matching size and shape to market using a MakerBot Replicator 2.

Notably in the extrusion process, little to no amount of the drug evaporated due to the heat, as authors state, “In all three cases, the recovery of haloperidol was close to 100% and within 1% of each other.”

Rapid relief

In the most successful experiment from Professor Serajuddin’s team, a polymer pill with 60% infill completed haloperidol release in just 45 minutes. In most other cases, non-porous tablets with 100% infill released the drug within 1 to 2 hours, still putting them within the “rapid relief” threshold.

In summary, “Such tablets may thus be suitable for immediate release dosage forms of drugs.”

Additionally, “The procedure adapted in the present study may be used for the development of FDM 3D printed tablets as immediate release dosage forms.”

Never miss a 3D Printing Industry news story again – subscribe to our newsletter, follow us on Twitter and like us on Facebook.

Featured image shows St. John’s University 3D printed pills. Photo via the Journal of Pharmaceutical Sciences