South Africa’s Industrial Development Corporation is investing R17 million (the equivalent of over $1.2 million USD) in Metal Heart, a startup to make metal 3D printers for production.

The investment is part of the country’s strategy to gain a competitive advantage in 3D printing, and create jobs in priority industries such as gas and energy, fuel cells, medical devices, and nanotech.

R107.1 million investment in just 2 years

The government-run Industrial Development Corporation has been active since 1940, as “the primary source of commercially sustainable industrial development and innovation to benefit both South Africa and the rest of Africa.”

This new investment in Metal Heart is from the IDC’s New Industries Strategic Business Unit (SBU). First established in 2015, the SBU has invested in 11 different companies to date, over half of which have been startups. In total, this unit alone has approved the investment of over R107.1 million (Around $12.4 million USD).

Another South African enterprise, the Aeroswift project, is aiming to produce the world’s largest titanium powder additive manufacturing machine for airplane parts. Aeroswift is also backed by the South African government. First announced in 2011, the project has since piqued the interest of international aerospace manufacturers Boeing and Airbus.

South Africa’s additive manufacturing roadmap

The South African Department of Science and Technology has commissioned a national Additive Manufacturing Technology Roadmap to guide investment in the country’s 3D printing industry over a period of 9 years. So far, the project has identified four priority areas for additive manufacturing research, development, and innovation, and Metal Heart matches each of them.

According to Department of Science and Technology priority additive manufacturing ares are:

- 3D printing processes and parts to meet aerospace and medical specifications.

- Having an impact on existing manufacturing processes.

- Material and technology to support 3D printing machines.

- The development of an additive based small to medium enterprise industry.

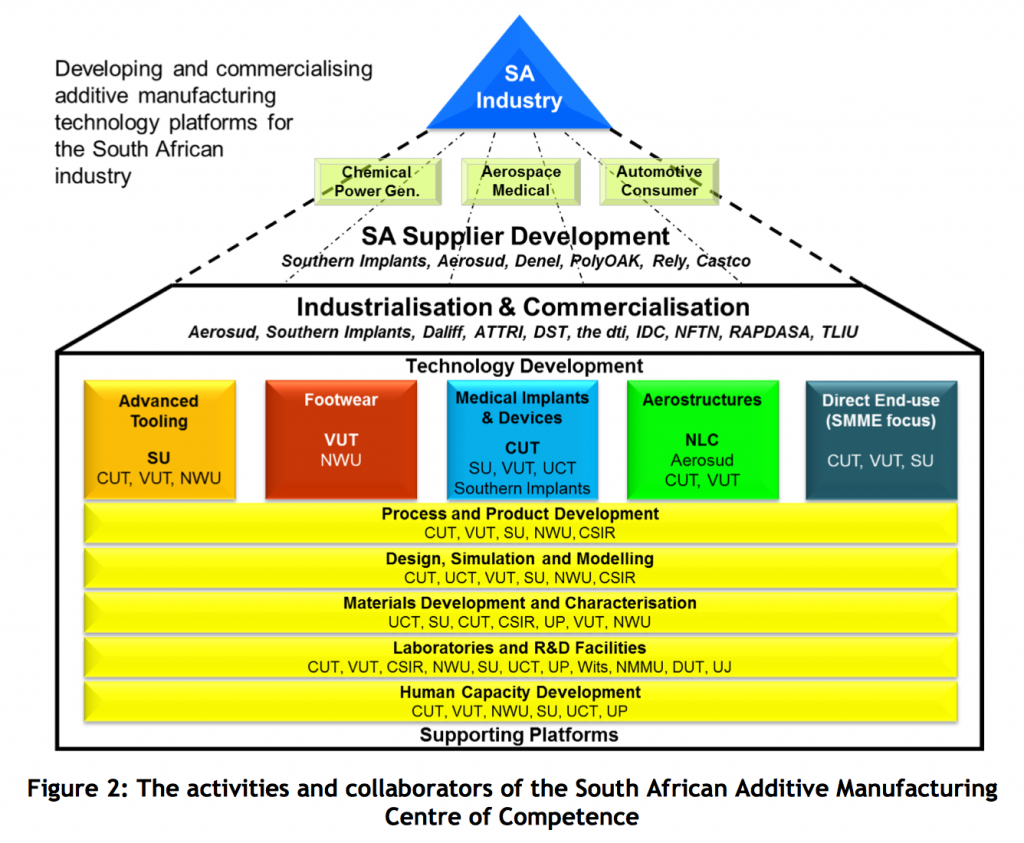

Picking up on the proposed roadmap, researchers at South Africa’s Central University of Technology, and North-West University have also proposed an Additive Manufacturing Center of Competence for the country.

The concept was first presented at the 15th Annual Rapid Product Development Association of South Africa conference in 2014. It is designed to guide 17 of the nation’s universities and research institutions through additive manufacturing projects to benefit high-value manufacturing industries.

To stay up to date with additive manufacturing news in South Africa and the rest of the world sign up to the 3D Printing Industry newsletter, and follow our active social media sites.

Don’t forget to vote in the first annual 3D Printing Industry Awards.

Tickets for the 3D Printing Industry Awards are also now available here.

Featured image: South African government invest in 3D metal printing startup in Gauteng, the province home to Johannesburg. Johannesburg skyline photo by Nico Roets on Flickr