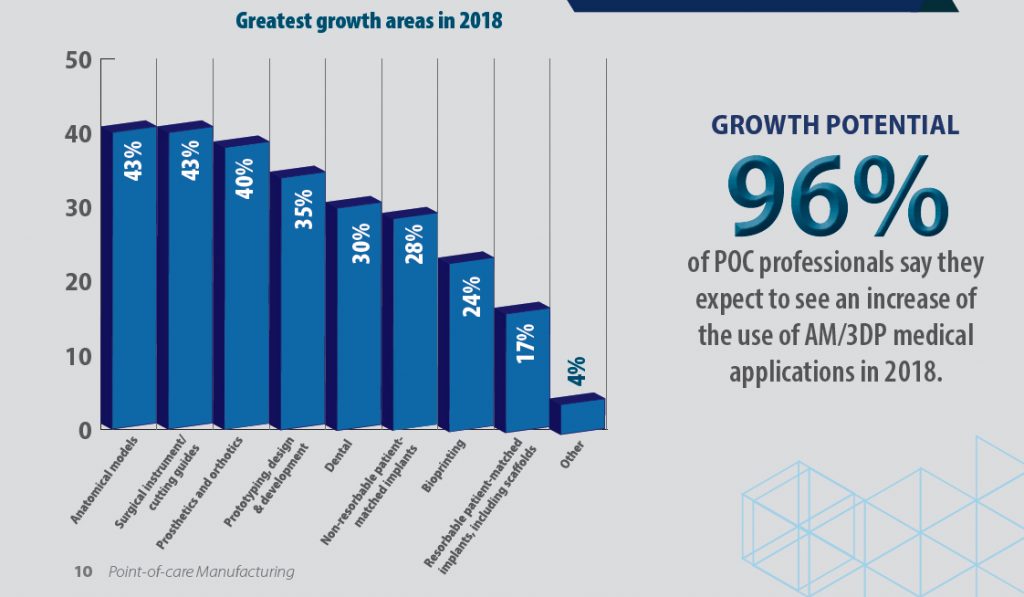

In a report published by SME, 96% of professionals 3D printing for point of care, e.g. medical models, prosthesis, implants and surgical guides, expect to see a rise in medical 3D printing throughout 2018.

In the report Lauralyn McDaniel, medical additive manufacturing industry expert at SME, explains that the rise is due to a number of patient oriented benefits generated by 3D printing on demand. “The number one priority for healthcare providers remains patient care,” comments McDaniel,

“The focus is helping fuel the rise of POC manufacturing enabled by additive manufacturing, providing benefits for patients and physicians/institutions including better patient outcomes, less time in the operating room and reduced costs.”

Conducted by the member organization that seeks to advance manufacturing across America, the report includes the input of more than seventy 3D printing in healthcare professionals including Fried Vancraen, CEO of Materialise, and Katie Weimer, Vice President of Medical Device Healthcare at 3D Systems.

Point of care in hospitals

Point of care is used to describe devices made “just-in time” for rapid treatment of a hospital patient. 3D printing for these devices is either done on-site, like at Phoenix Children’s Hospital Arizona, or by contract manufacturers, as in the case of 3D Systems’ aid in the separation of the conjoined McDonald twins.

Through a number of case studies, the report collates data on the apparent rise of the technology as noted by experts.

FDM on top

Unsurprisingly, as the most cost-effective and widely available technology, Material Extrusion (FDM, FFF, MEM) is the most common 3D printing for point of care devices.

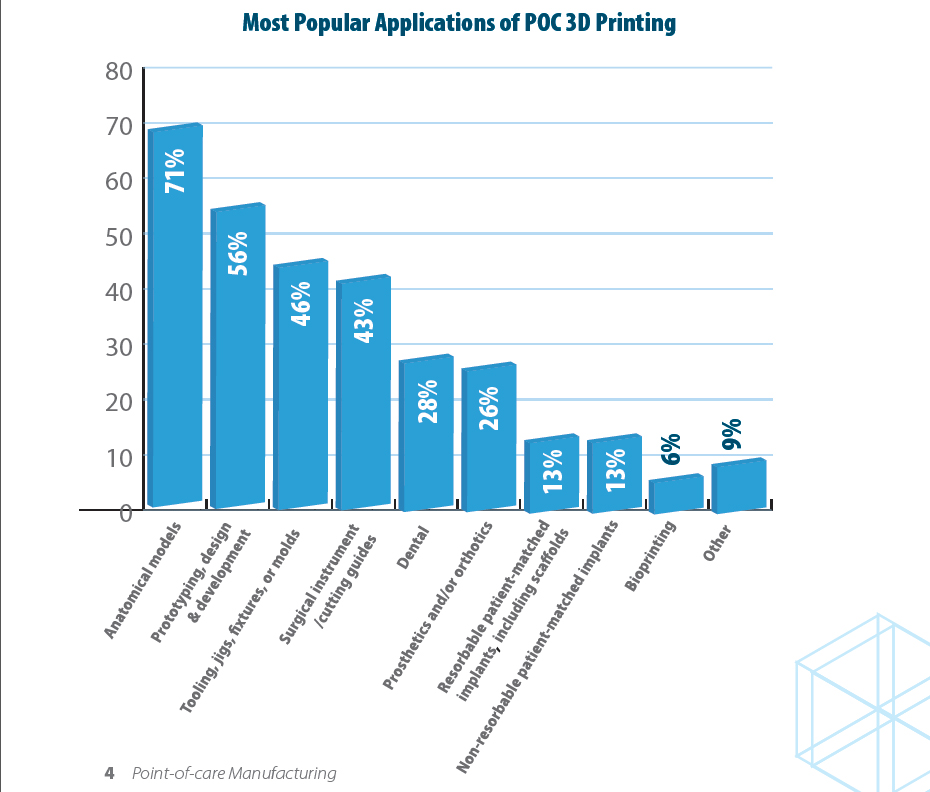

In applications, anatomical models are expected to have the highest rate of growth at 71%, followed by rapid prototyping and product development (56%) and tooling, jigs, fixtures and molds (46%).

At present, anatomical models are most commonly used in surgical planning for sensitive procedures a point that may shift in the near future.

Writing in one of the report’s use cases Katie Weimer, Vice President of Medical Device Healthcare at 3D Systems, comments, “Today, the healthcare 3D printing industry largely uses legacy industrial prototyping materials. As the industry evolves, I believe we will have a bigger impact on patient care when our materials better replicate the

human body.”

“I believe we will see a revolution into more biomimetic materials for 3D printing in the healthcare industry.”

A full view of 3D printing in healthcare

Interestingly, the report also states that 16 of the U.S. top 20 hospitals (as ranked by the U.S. News and World Report) have implemented a medical 3D printing strategy in recent years. Materialise has reported a 3200% rise in centralized 3D printing facilities using Mimics technology in the U.S. between 2010 and 2016.

The full white paper from SME can be read online here.

Make your nominations for medical advance of the years in the 2018 3D Printing Awards now before they close on tomorrow.

For all the latest trends for 3D printing in healthcare subscribe to the most widely read newsletter in the industry, follow us on Twitter, and like us on Facebook.

Protolabs is sponsoring the 2018 3D Printing Industry Awards design competition. Submit your design for chance to win a 3D printer.

Featured image shows a Stratasys 3D printed anatomical heart. Photo via: Stratasys on Facebook