SLM Solutions, a German provider of metal additive manufacturing systems, has released more information about working with Bugatti, the French manufacturer of high-performance automobiles. The new information shows how 3D printing is used to develop critical components.

Last year, the partners created a 3D printed brake caliper for the Bugatti Chiron. Recently the component underwent testing for serial production.

Now, SLM Solutions has presented further details on other metal 3D printed functional components from Bugatti; these include a 3D printed spoiler and motor brackets as well as cylinder head covers and front axle differentials.

A 3D printed brake – through

Bugatti’s 3D printed titanium brake caliper was made on an SLM 500 3D printer. Upon testing, Frank Götzke, Head of New Technologies at Bugatti, said “the caliper showed a tensile strength of 1,250 N/mm2 and a material density over 99.7%.”

Götzke added that the results demonstrate that additively produced metal components can cope with extreme strength, stiffness and temperature requirements at speeds of over 375 km/h and brake disc temperatures up to 1,100°C.

A lightweight supercar

Following the success of the 3D printed caliper, Bugatti is now using SLM additive manufacturing for lightweight and aesthetically pleasing components. “We always strive for absolute perfection, stylistic as well as technical, as well as considering the perfect synergy of both elements,” added Götzke.

An example active titanium spoiler bracket was manufactured on the SLM 500 in collaboration with Fraunhofer IAPT. This spoiler is said to enhance the aerodynamic design of Bugatti vehicles.

Bugatti teamed up with Siemens, Europe’s largest industrial manufacturing company, to optimize this bracket for production as well as 3D printed small motor brackets – parts designed to support the engine and transmission assemblies. The motor bracket has been installed in all Bugatti series vehicles since the delivery of the first Bugatti Chiron to the Molsheim, France production facility.

With additive manufacturing, the weight of the spoiler bracket was reportedly reduced by 5.4kg, 53% from the original with increased rigidity. Furthermore, the 3D printed motor bracket has now been integrated with water cooling acts which significantly reduces transferred heat from the car’s engine.

Driving the automotive sector

The partnership between Bugatti and SLM Solutions began in 2014 with the development of 3D printed front axle differential housing produced on the SLM 280. This component distributes power from a vehicle’s transmission while enabling the wheels to rotate.

Additionally, at Formnext 2018, the partners showcased eight Bugatti W16 cylinder head covers built on the SLM 800. Each hood measures 285mm wide and 65mm thick with a height of 735mm. Both companies are continuing to apply metal additive manufacturing to automotive end-use parts.

For the latest updates from IDS 2019, subscribe to the 3D Printing Industry Newsletter, join us on Twitter and Facebook.

Also, we have plenty of jobs in the industry, visit our 3D Printing Jobs page.

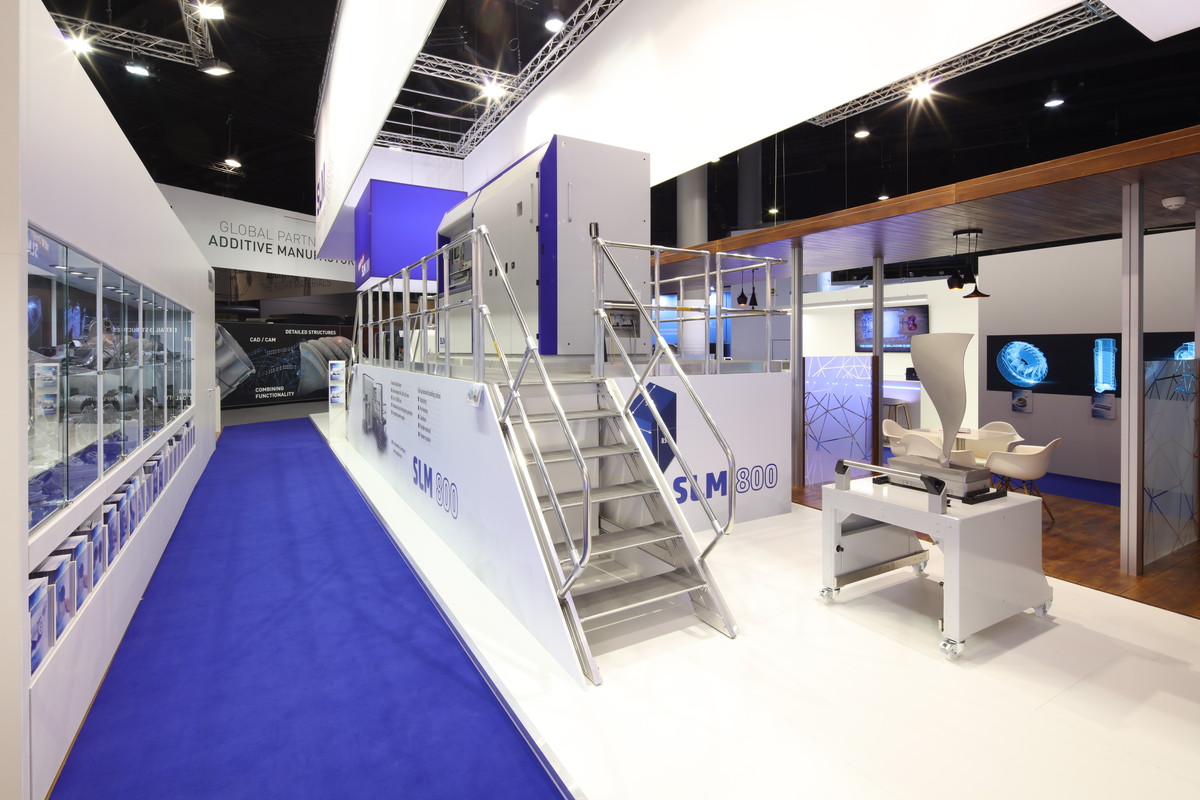

Featured image shows the 3D printed spoiler bracket. Photo via SLM Solutions.