German 3D printer manufacturer SLM Solutions has printed a proof of concept E-drive housing for Porsche on its recently released NXG X11 600 3D printing system.

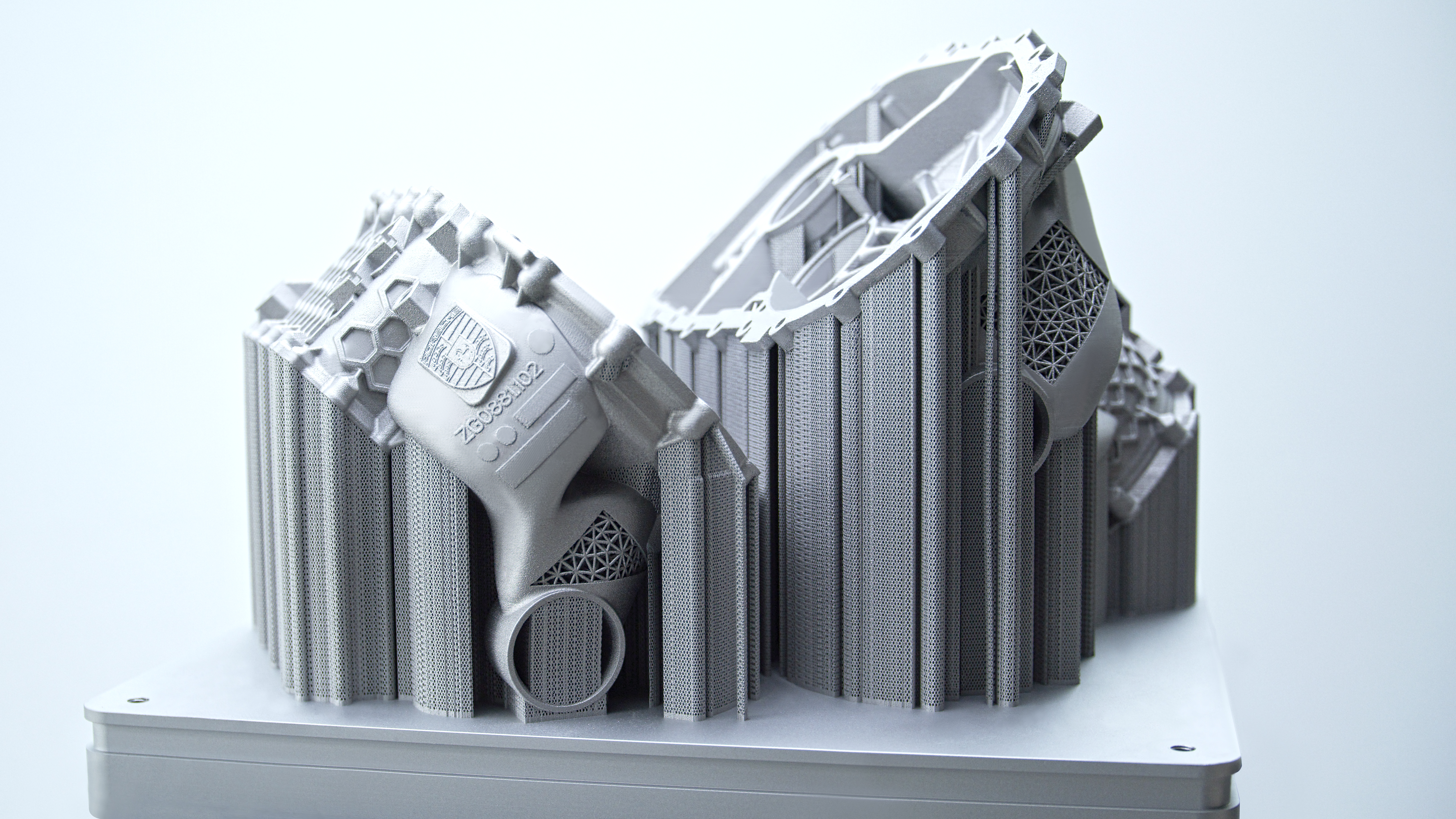

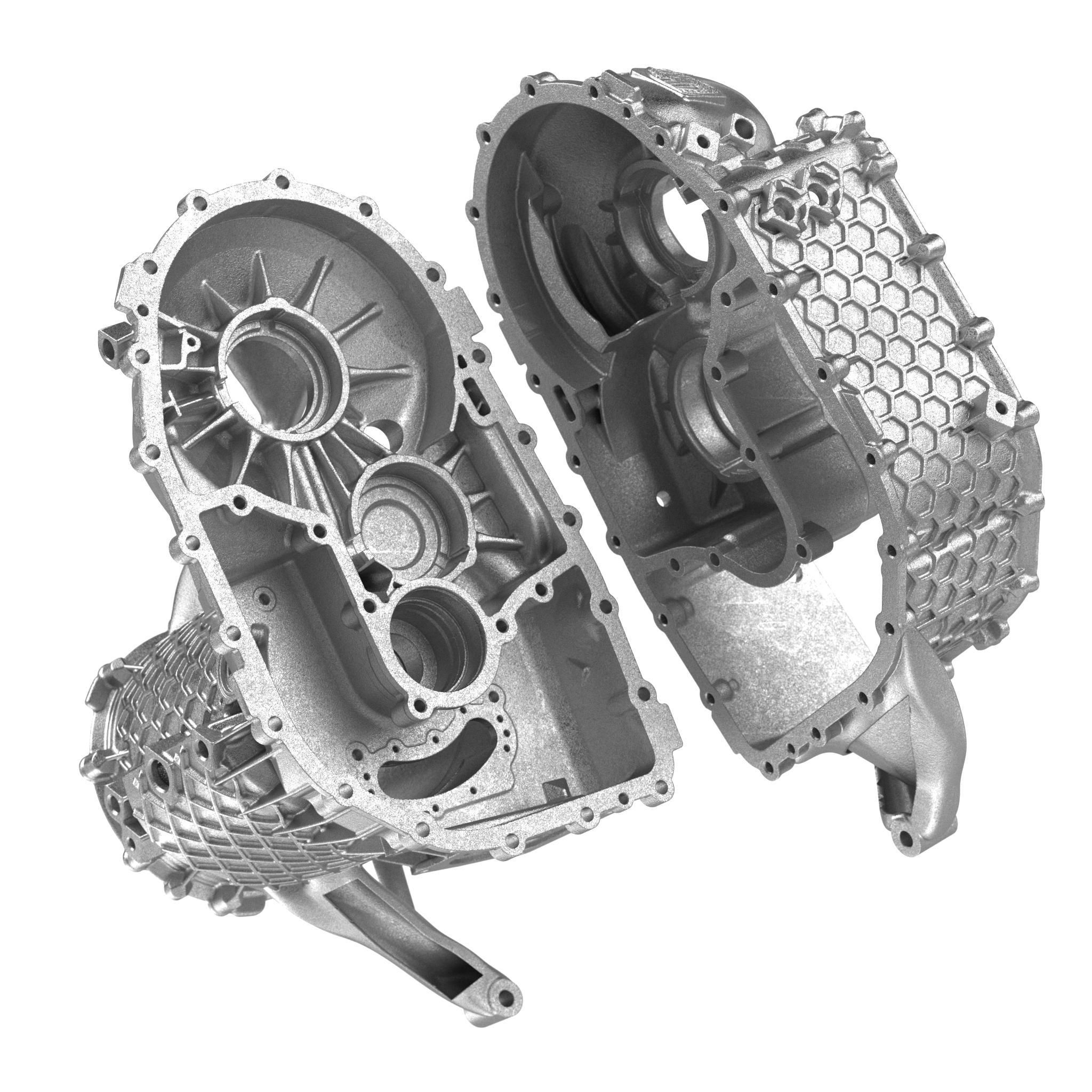

Made up of an integrated two-stage transition and a motor, the 3D printed housing is designed for use on the front axle of a sports car.

“This new manufacturing technology is technically and economically interesting for us,” said Falk Heilfort, powertrain development engineer at Porsche. “Possible use cases are especially prototypes in the development phase, special and small series production as well as for motor sport and classic spare parts.”

SLM technology

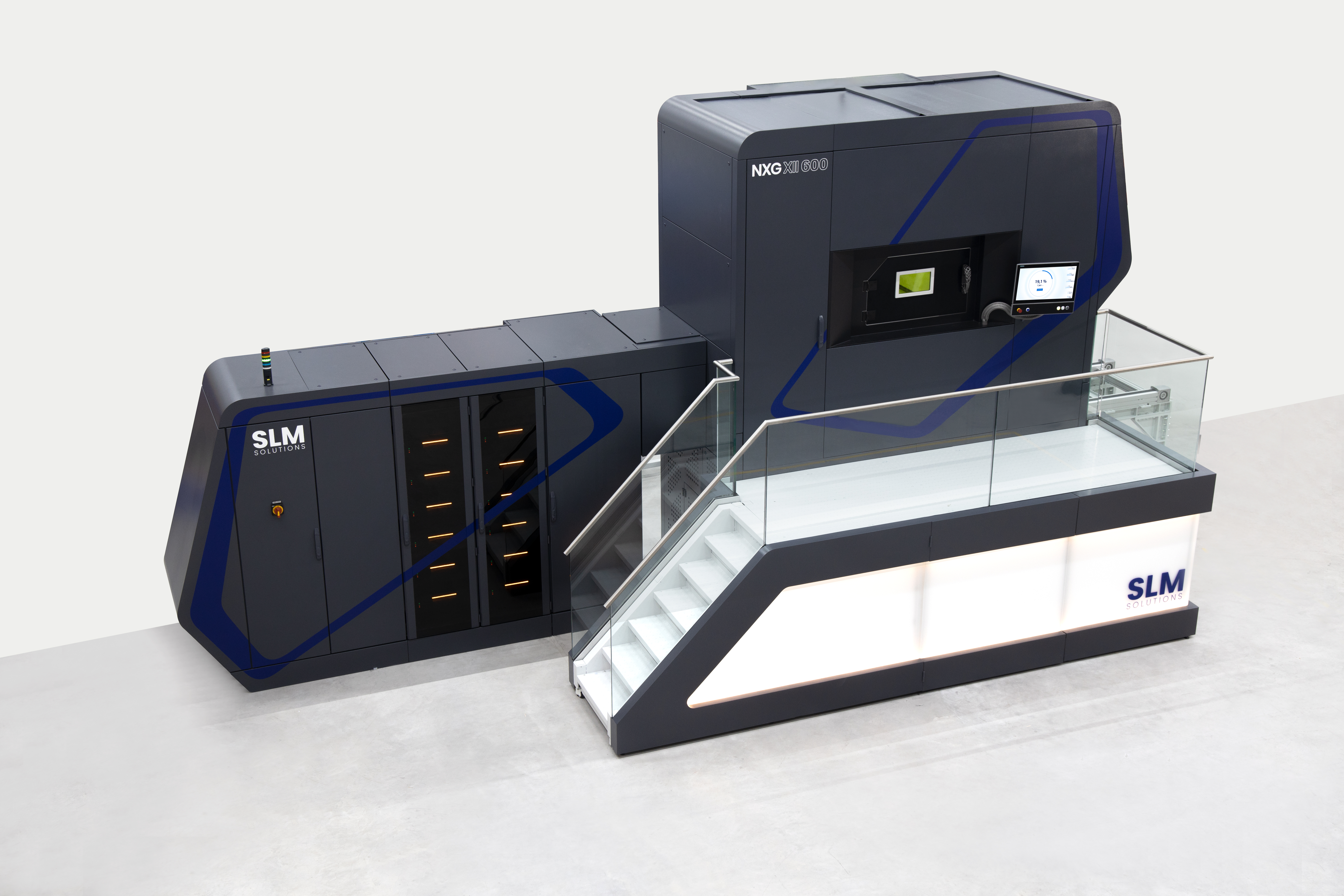

SLM Solutions is a specialist in developing and producing Selective Laser Melting (SLM) additive manufacturing systems. SLM uses high powered lasers to melt metal powder along pre-defined pathways, enabling the rapid creation of intricately shaped parts. In addition to the recently launched NXG X11 600, the firm’s current machine portfolio includes the SLM 125, SLM 280, SLM 500, and SLM 800 systems.

SLM released its large format NXG X11 600 in November at Formnext Connect, custom-designed to mass produce large parts. The machine is equipped with 12 overlapping 1 kW lasers which can operate simultaneously, and combined with a build envelope of 600x600x600mm, facilitates the production of large-volume spare parts with up to 120 µm layer thickness. The printing system also features variable beam spot, bi-directional recoating, laser balance, and an optimized gas flow to enhance productivity.

Printing the E-drive housing

SLM has collaborated with Porsche’s advanced powertrain engineering department, which is seeking to explore the potential for producing automotive components such as E-drive housings, cylinder blocks, and cylinder heads through additive manufacturing.

Using the NXG X11 600, SLM printed a complete proof of concept E-drive housing for the automotive manufacturer in just 21 hours. Integrated within the housing was a permanent magnet motor capable of delivering 280 hp, and a downstream two-stage transmission to drive the wheels with up to 2,100 Nm of torque.

The housing was printed with lattice structures in order to optimize topology of the part and reduce its weight. SLM’s 3D printing technology also enabled the functional integration of cooling channels to be improved, in addition to increasing part stiffness. The time taken to assemble the part was significantly reduced as a result of integrating the parts into the single E-drive housing, and reportedly overall part quality was improved as well.

“We are glad and proud to cooperate with highly innovative companies like Porsche,” said Ralf Frohwerk, Global Head of Business Development of SLM Solutions. “The NXG X11 600 achieves unmatched levels of performance and functional improvements of key automotive parts while delivering cost productivity that enables broad use of additive manufacturing technology for true series production.

“We are thrilled to take this big step towards full industrialization of metal additive manufacturing for Porsche.”

3D printing performance vehicles

Porsche is no stranger to 3D printing, having previously worked with machine tool producer TRUMPF and automotive parts company MAHLE to 3D print pistons for the engine of its flagship 911 supercar. The Laser Metal Fusion (LMF) technology added 30 bhp to the engine and achieved a 10 percent weight reduction in each piston.

Prior to this, the automotive manufacturer has embarked upon printing spare parts for its rare and classic cars, and announced it would be 3D printing personalized bucket seats for prototypes to be used on European race tracks.

Elsewhere in the automotive sector, start-up Czinger is set to launch its first 3D printed hypercar, the 21C, in 2021, while automotive manufacturer Continental AG recently installed a Stratasys Fortus 450mc FDM 3D printer at its Additive Design and Manufacturing (ADaM) Competence Center in Karben, Germany. The printer will be used to manufacture functional prototypes, end-use parts, and jigs and fixtures for the company’s own production line.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Be sure to subscribe to the Another Dimension podcast on your chosen podcast player to make sure you never miss an episode.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows 3D printed E-drive housing for Porsche. Image via SLM Solutions.