Skyrora, an Edinburgh-based private rocket manufacturer, has completed a 70kN hot-fire test for its fully 3D printed rocket engine, which is slated for use in the company’s XL launch vehicle.

The success marks a key step in the firm’s ongoing contract under the Commercial Space Transportation Services and Support Programme (CSTS) of the European Space Agency (ESA).

Conducted at Skyrora’s test site in Gorebridge, Midlothian, the hot-fire test was the latest in a series of 16. It lasted a total of 20 seconds, was completed with all requirements met, and used a different propellant mixture ratio than the previous tests.

Volodymyr Levykin, founder and CEO of Skyrora, said, “Without the tireless efforts of our international team, this milestone wouldn’t have been possible. Everybody’s insights have been invaluable, and their spirit is a true testament to the passion shared by everyone at Skyrora.”

Skyrora shoots for the stars

Founded in 2017, Skyrora has its sights set on being the leading orbital space launch company in the UK. The firm is currently targeting the small satellite market and leverages both in-house 3D printing and conventional manufacturing processes to produce its rocket components.

Announced in 2019, Skyrora’s Gorebridge test site was established in March 2022 and is reportedly the largest of its kind in the UK. Measuring over 120,000 square feet, the facility uses rainfall from the Scottish Lowlands to cool and dampen the sound of the test stand.

Just last year, the company also successfully completed trials of the third stage of its Skyrora XL rocket. The launch vehicle will reportedly be able to refire its engines around 15 times once in orbit, completing tasks such as tugging and de-orbiting defunct satellites. In October 2021, Skyrora announced a multi-launch agreement with spaceport SaxaVord, enabling the company to complete 16 launches a year by 2030.

More recently, the company developed what it claims to be the largest hybrid 3D printer of its kind in Europe. Based on the existing Skyprint 1, the Skyprint 2 is set to be fully operational later in 2022 and will be used to manufacture large-format rocket engine parts up to 2.3m in length.

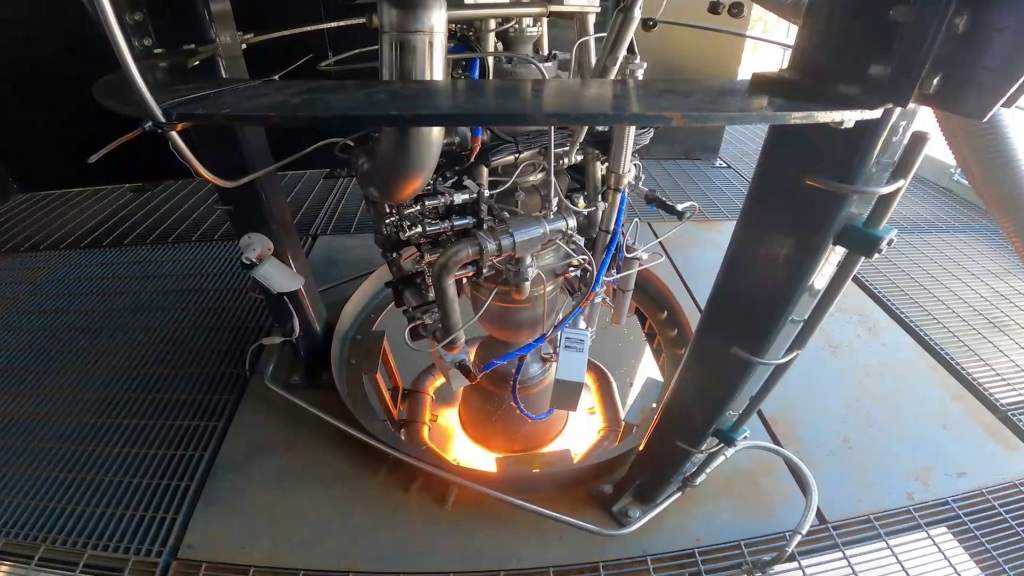

The 70kN engine test

Designed and 3D printed on-site at Skyrora’s recently-launched new vehicle assembly facility, the 70kN rocket engine is a critical component used in the first and second stages of the firm’s XL orbital launch vehicle. According to the company, many of the engine’s elements were based on the old-school Black Arrow Gamma 8 rocket design, drawing inspiration from the UK’s aerospace legacy.

Once qualified, the engine will be the first staged combustion engine to operate on high-test peroxide (HTP), a novel liquid rocket propellant.

Dr Jack James Marlow, Skyrora’s Head of Engineering, said, “The engine passed its final development test with all data nominal and all system requirements met, which is a fantastic team achievement. Our unique engine uses HTP to power the turbopump, in a closed-cycle approach as opposed to Black Arrow’s open-cycle. This means we have higher engine efficiency while keeping the overall system simple. This allows us to deliver a greater payload to orbit for our customers.”

With the latest test now complete, the next round of qualification tests has been unlocked. The engine in question will be disassembled, refurbished, and qualification tested to bring the company one step closer to propulsion system integration and stage testing. Skyrora has also expressed plans to scale up its manufacturing process, with qualification tests expected to be ramped up to one engine a week.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the 3D printed engine during the 70kN test. Photo via Skyrora.