The Skolkovo Institute of Science and Technology (Skoltech) has opened a new, state-of-the-art Additive Manufacturing Laboratory (AM Lab) in Moscow.

Operating within the institute’s Center for Design, Manufacturing and Materials (CDMM), the AM Lab will work with Swiss technology conglomerate Oerlikon, and the Technical University of Munich (TUM) to boost the skillset of engineering students, and narrow the gap between academia and industry.

Making waves with additive at scale

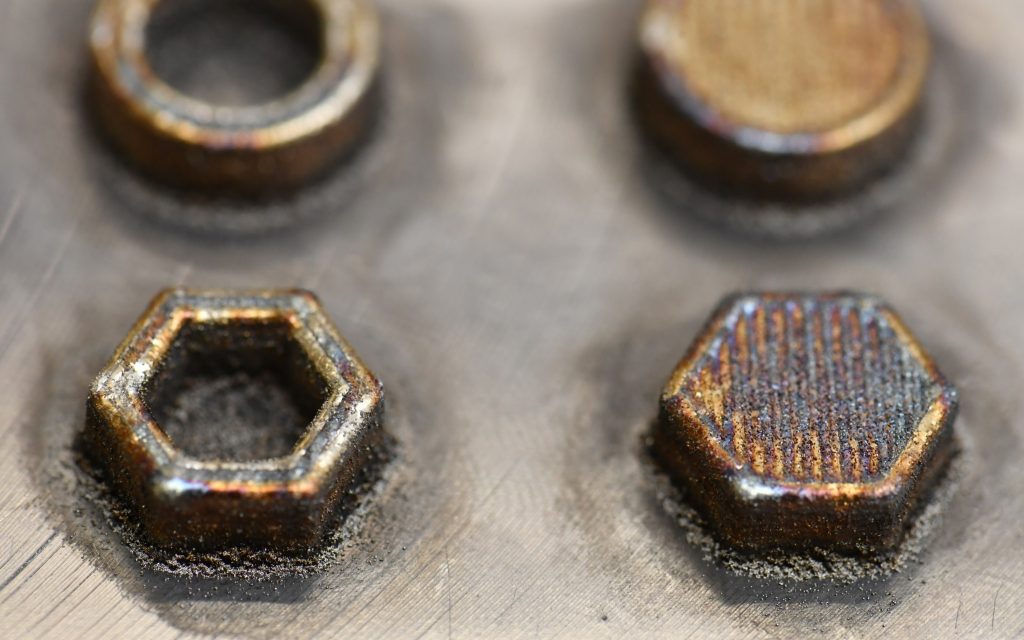

Skoltech’s AM Lab is equipped with industry leading 3D printing systems capable of working with metal alloys, ceramics and polymers. Among the machines is a Trumpf TruPrint 1000, 3D Ceram Ceramaker 900 and a Projet 3D printer from 3D Systems.

With a build envelope of 1,000 x 800 x 650 (mm) the Insstek MX 1000 is the crowning glory of the facility, taking the title of “the biggest 3D printer in Russia” to date.

Fardad Azarmi, a professor from North Dakota State University who assisted with establishing the lab, comments, “In particular, the metal and ceramic printers are unique and in very high demand, and I’m sure they’ll attract interest from industry,”

“One of the main goals of the lab will be to promote these technologies in Russia and around the world.”

Addressing the skills shortage

As a relatively new technology, one of the main challenges to the proliferation of 3D printing is finding engineers skilled in additive design and machine operation. The skills shortage in this area is something Professor Iskander Akhatov, Director of Skoltech’s CDMM, hopes will be addressed by the AM Lab. “I think there is a lack of basic research today,” he explains, “researchers in this field often just do simple engineering,”

“Our goal is to explore the possibilities of these technologies in a comprehensive way, to understand the right application of these technologies, and the right regimes and methodologies of using them.”

Collaboration is key

A collection of strategic partnerships will be key to the AM Lab’s success. Dr. Michael Süss, Chairman of the Oerlikon Board of Directors, states, “For the first time in the last few centuries, humankind is facing the choice of a new kind of manufacturing. This is an enormous challenge, and success is not yet guaranteed. One thing is clear: if we try to obtain results on our own, we will fail.”

In addition, Skoltech’s mathematical expertise, according to Professor Süss, is an important factor considering the next industrial revolution. “This new type of production,” he adds, “is only possible due to the ongoing digitalization of the economy, and the growing power of computers that allow us to create complex mathematical models.”

“This is the strength of Skoltech, where a brilliant team of mathematicians has assembled under the leadership of President Kuleshov.”

Stay up to date with the latest 3D printing developments – sign up to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Looking for a change in specialism? Register for jobs in 3D printing here.

Featured images shows visitors to Skoltech’s AM Lab receiving a demo of the Insstek MX 1000 system. Photo via Skoltech.