Sinterit, a Polish manufacturer of SLS 3D printers, has announced a number of feature updates for its proprietary Sinterit Studio software.

Sinterit Studio is designed for use with the company’s desktop Lisa and Lisa Pro 3D printers, and provides users with end-to-end print management functionality from part slicing to real-time build monitoring. Available in four different versions, users can either opt for a free variant of the software or one of the paid premium versions for additional material capabilities.

Paweł Szczurek, co-founder and technical project manager at Sinterit, explains, “Our software guides you, step-by-step, through the whole SLS 3D printing process. Sinterit Studio is designed to make your workflow smooth and simple, from loading your model through to arranging the objects, to monitoring the state of your printer until the printout is finished.”

Streamlining SLS with auto-nesting

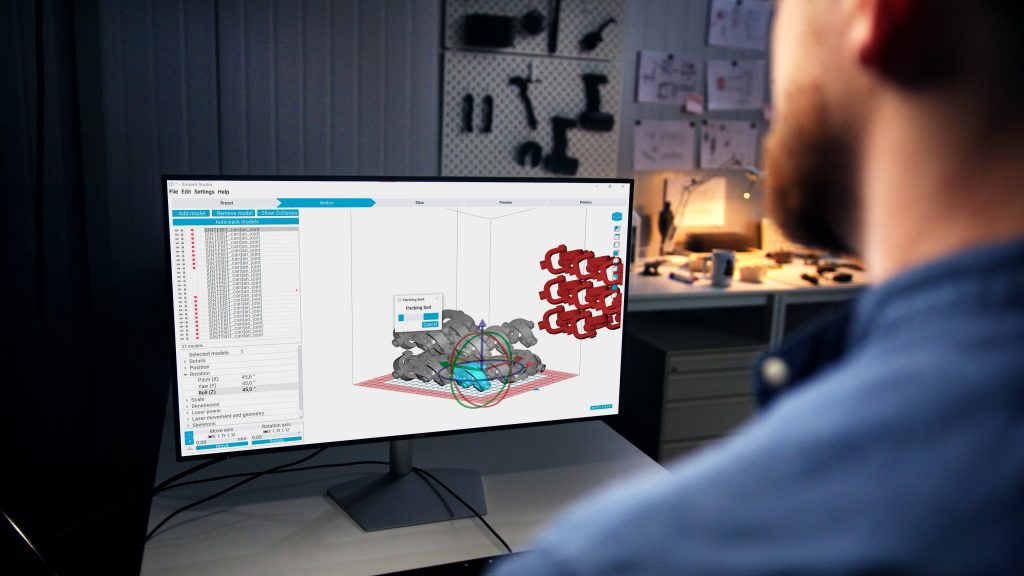

The biggest of the upgrades is the new auto-nesting feature available with Sinterit Studio. With the click of a button, users can now automatically arrange their models on the build plate in an optimized formation, which can be particularly handy with high-volume, multi-part builds.

Before the update, users would have had to do this manually, duplicating each of their models in the XY plane and elevating some of the parts in the Z-axis as and when needed. The auto-nesting feature, as well as significantly reducing the build preparation time, also works to optimize the overall printing time and material costs of the build.

Michał Grzymała-Moszczyński, co-founder and CTO of Sinterit, adds, “Sinterit was the first company in the world that brought SLS technology to the benchtop market. Over the past years, we have been developing products by listening to our customers, and today we want to meet their needs again by improving the SLS experience.”

The importance of open parameters

As well as auto-nesting, Sinterit has introduced a number of new open parameters in the Sinterit Studio software, which users can modify based on their needs. Ultimately, the addition enables a greater level of control over the Lisa and Lisa Pro 3D printers, and is expected to be particularly useful for universities working on R&D projects.

Users will now be able to fine-tune four different temperature settings for each of the 22 heating elements present in Sinterit’s 3D printers, as well as parameters such as laser power, laser movement, the shells of the parts, and the skeletons of the parts. As such, researchers in the field of materials development will be able to optimize their printing processes for custom research methodologies based on powder validation, final part mechanical properties, and surface quality.

Grzymała-Moszczyński concludes, “The temperature distribution is crucial in the SLS printing process. That is why it is paramount that we provide the ability to control each of the heaters in our printer, giving users the opportunity to work with new materials and create high-quality printouts.”

The past year alone has seen Sinterit making major moves in all aspects of its business, beyond just the software side. For example, the company recently launched a Powder Handling Station (PHS) that it claims will take post-processing ‘to the next level’. The device streamlines and accelerates the powder recovery process by integrating each of Sinterit’s post-printing accessories into one ergonomic platform.

Sinterit also recently added a new electrostatic safe 3D printing powder to its materials portfolio. PA11 ESD is the company’s seventh SLS powder, but the first to feature electrostatic discharge (ESD) functionality, which enables the production of conductive parts with dissipative qualities.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Sinterit Studio 2019 software. Photo via Sinterit.