Lynxter, a France-based 3D printer manufacturer, has announced a new financing round of 4 million Euros in series A funding. The funding will support Lynxter’s mission to develop innovative additive manufacturing solutions for industry, healthcare, and education. Since completing a seed round of €1.5 million in 2019, Lynxter has broadened its ecosystem and begun expanding into North America.

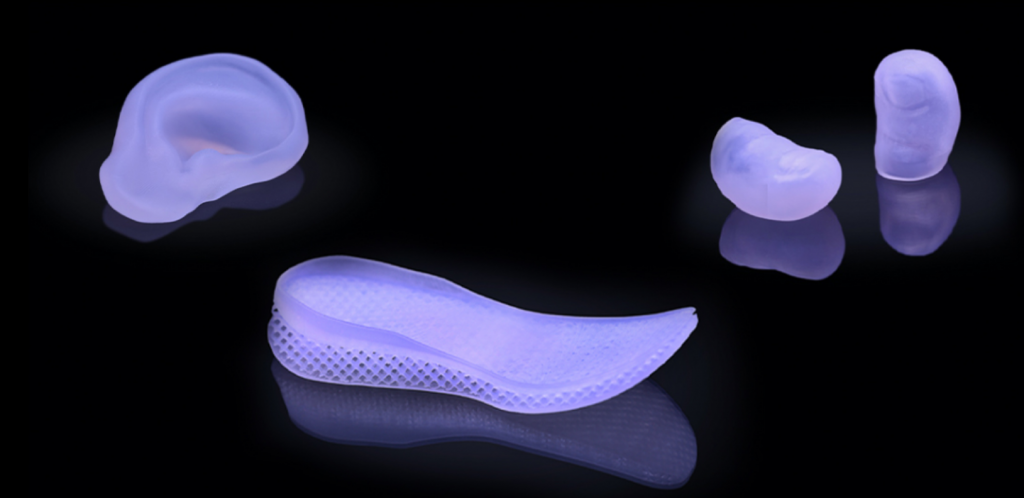

Lynxter makes a range of 3D printers designed to use materials including carbon PA, PP, PEKK, polycarbonate, TPU, and porcelain. Where the company stands out is their ability to 3D print silicone. Lynxter describes their S300X 3D printer as, the “leading professional 3D printer for silicone and polyurethane additive manufacturing in medical and industrial sectors as well as R&D.”

Existing investors and new partners, such as Group Etchart, NACO, Pyrénées Gascogne Dévelopement, and HERRIKOA, have joined the funding round. Lynxter intends to use the funding to export its innovations to additional countries, strengthen its team by adding approximately ten team members in 2023, and continue innovation, preserving and enhancing its research-based identity.

Customers of Lynxter include major corporations like Airbus, Schneider, Sanofi, and Renault. A statement issued by the company stated, “Lynxter is grateful to all persons and entities who supported us throughout this important round of funding: The Line, INLO, and Aldearran Advisors have proven their effectiveness, value, and professionalism.”

Silicone 3D printing

In 2019, German RepRap, now renamed innovatiQ, launched the L320, a Liquid Additive Manufacturing (LAM) 3D printing system with a larger build volume than its predecessor, the L280. Designed for processing 3D printing liquid silicone rubber, the L320 offers a highly stable system suitable for industrial continuous operation. Unlike traditional material extrusion technologies, LAM deposits liquid material, which is then vulcanized into a solid object through exposure to a heat lamp between layers. This method provides equal strength across the X, Y, and Z axes, making it suitable for both low-volume prototyping and serial production. The L320 has a print speed range of 10 to 150 mm/s, positional accuracy of +/- 0.2 mm/s, and can produce layer heights between 0.22 and 0.9 mm.

Also that year, 3D Printing Industry caught up with Spectroplast after the company won the Formnext Startup Challenge for their silicone 3D printing service. Spectroplast is a Swiss-based company founded in 2018 as a spinoff from ETH Zurich. They specialize in producing high-precision real silicone 3D prints. They position themselves as a complementary process to liquid injection molding, suitable for manufacturing small and medium series production of finished products and functional prototypes. Spectroplast is focused on the healthcare and medical sectors and plans to target necessary compliance certification for introducing a medically certified silicone material to the world of additive manufacturing.

In 2021, The Digital Manufacturing Centre (DMC) in Silverstone Park became the UK’s first provider of silicone additive manufacturing (SAM) services, using a process developed by ETH Zurich spin-off Spectroplast. This 3D printing technique uses 100% biocompatible silicone as raw material, allowing for the production of personalized medical devices with minimal waste and lead times. The Spectroplast process, which is ISO DIN EN10993-05 and EN10993-10 certified, can cut lead times from six weeks to five days and reduce the overall cost per part by up to 50% for certain volumes. The technology is expected to have applications in the general engineering sector as well, such as gaskets, seals, and dampers.

For all of the latest 3D printer releases subscribe to our newsletter, follow us on Twitter, and like us on Facebook. Find talent for a project, or advance your career in 3D printing – join 3D Printing Jobs to apply and advertise.

Featured image shows the Lynxter Team. Photo via Lynxter.