Australia’s Conflux Technology has received a “significant” investment from AM Ventures to advance the functional applications of metal additive manufacturing. The company is a specialist in 3D printing thermal components.

I asked Conflux Technology founder and CEO Michael Fuller more about the news.

Additive manufacturing investment fund

Founded by EOS Group CEO Dr. Hans J. Langer in 2015, AM Ventures scouts promising additive manufacturing enterprises of the future and aims to make industrial 3D Printing a key manufacturing technology.

AM Ventures has invested in numerous start ups focused on making the future of additive manufacturing a reality, including Exmet AB – additive manufacturing of amorphous metals – and industrial 3D printing platform, 3YOURMIND.

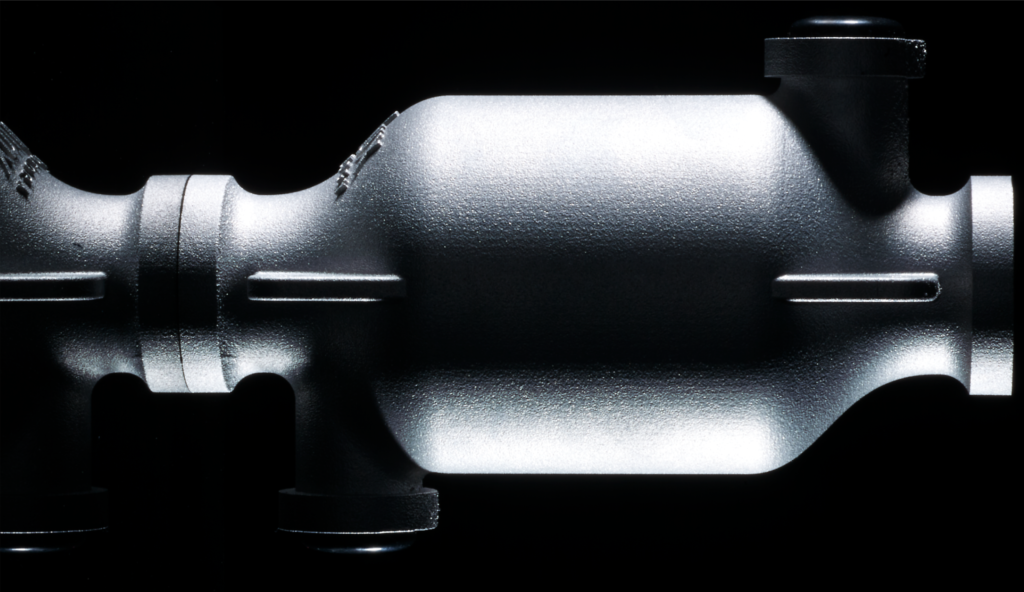

With a combined 30 years of 3D printing engineering experience – including stints as a consultant to the Mercedes-AMG F1 Team and Sauber Motorsport AG, Conflux Technology and their patent pending Conflux Core™ heat exchanger are building the, “next generation in high efficiency thermal management technologies.”

Michael Fuller explains, “The patented Conflux Core heat exchanger is applicable in the short term in Aerospace, Motorsport and Automotive. In the medium term, our markets then open up with Chemical processing, Oil & Gas, High Performance Computing etc. Heat exchangers are ubiquitous and therefore make for a compelling example of an AM application.”

Hitherto unimaginable internal geometries

The 3D printed heat exchangers leverage the geometric freedom and structural efficiency that comes from AM.

Made using EOS M290 & M400 additive manufacturing machines the devices have a high surface area density and optimised fluid pathways. According to the company this, “produces a high thermal exchange, low-weight, low-pressure drop-heat exchanger. The performance advantages were achieved within a rapid development timeline and with a minimum of prototype iterations.”

Fuller says, “Heat exchanger performance is entirely geometry dependent. AM offers new opportunities with hitherto unimaginable internal geometries for optimising heat flux, pressure drop and morphed topology.”

While details of the investment amount are not public, 3D Printing Industry understand that the Conflux Technology will be making some exciting key hire announcements soon.

AMV’s Director of Business Development, Arno Held, had this to say about the latest member of the portfolio,

We are particularly happy about this opportunity, as the Conflux team has impressively demonstrated how well it understands metal AM technology. Complex structures in challenging environments require not only the highest standard of machine technology to produce parts but also the best engineering skills to design the right products. Conflux’ capabilities will become a great addition to our already excellent portfolio of Additive Manufacturing related companies.

Conflux say the investment represents a “step change in Australia’s AM capabilities and the validation of Federal Government innovation policy.” The company also acknowledges the importance of partnerships, specifically the CSIRO and Deakin University.

For all the latest 3D Printing Industry news, subscribe to our free newsletter here and follow our active social media accounts.

Featured image shows the Conflux Technology additive manufactured Conflux Core™ Heat Exchanger.