Two pieces of news show how Sigma Labs’ PrintRite3D software will be used by Materialise and Northwestern University.

Santa Fe-based Sigma Labs has signed a contract to implement its quality assurance software for metal additive manufacturing at Northwestern University for the first time. Furthermore, Sigma Labs has signed a joint sales agreement with Belgium headquartered Materialise, advancing an earlier MoU to develop an integrated in-situ quality assurance system for metal 3D printing.

PrintRite3D software

PrintRite3D is an in-process quality assurance (IPQA) software package for metal additive manufacturing, providing real-time melt pool analytics. The software reads thermal signatures to monitor the quality of 3D printed parts while they are being fabricated. This real-time, layer by layer analysis allows users stop the production of defective parts before they are complete, saving on time and material costs. The result is an overall reduced error rate and higher yields.

Machines can be retrofitted with the software. It is currently being evaluated by tier-1 aerospace and OEM partners across the globe.

Northwestern University’s adoption of PrintRite3D

The real-time melt pool analysis technology will be utilized by Northwestern University’s Northwestern Initiative on Manufacturing Science and Innovation (NIMSI) and Center for Hierarchical Materials Design (CHiMaD).

The PrintRite3D system will be integrated with a DMG Mori LASERTEC12 SLM machine to validate the capabilities of Sigma Labs’ technology while also providing Northwestern University with intelligent in-process quality assurance.

“We are honored to have the opportunity to work with Northwestern University,” said Mark Ruport, Executive Chairman of Sigma Labs. “This type of collaboration is critical if additive manufacturing is to realize its potential and reach full industrialization.”

The teams at NIMSI and CHiMaD have been collaborating on a predictive ICME (Integrated Computational Materials Engineering) tool for AM. The aim is to develop novel manufacturing methods and new alloys for 3D printing. With Sigma Labs’ new tool, the University believes its work will be furthered significantly.

“Sigma Labs provides us with one critical element in our ICME framework for model validation and for process control. We look forward to our collaboration to bring the science and technology of additive manufacturing to the next level,” said Jian Cao, Professor of Mechanical Engineering and Director of NIMSI.

The Materialise joint sales agreement

The joint sales agreement between Sigma Labs and Materialise stands to evolve the two companies’ previously announced MoU to cooperate on the integration of the Materialise Control Platform (MCP) with Sigma Labs’ PrintRite3D technology.

The MCP is an embedded hardware and software tool designed to give full control of the additive manufacturing process to the end-user. PrintRite3D has already been integrated with the MCP so the two companies are now poised to retrofit existing metal AM machines with the closed-loop control system.

Mark Ruport, Sigma’s executive chairman, stated: “Growing our partnership with Materialise is a significant milestone for Sigma Labs as we expand our footprint in the market and add momentum to our quest to broaden industry access to our groundbreaking PrintRite3D software.”

He adds, “The alignment is a natural step for both companies, as Materialise has a strong presence in the additive manufacturing market and a reputation for quality products. Commercializing and jointly selling this integrated solution will benefit both companies as well as advance the forward momentum of innovation in the 3D manufacturing industry.”

Sigma Labs has a history of collaborations around its proprietary PrintRite3D software. Just last year, the software company partnered with Airbus to qualify metal additive manufacturing for the serial production of aerospace components. Also last year, Sigma Labs became a member of the UK’s Manufacturing Technology Centre (MTC). As a result, the company enabled in-process quality monitoring for additive manufacturing systems at the MTC’s National Centre for Additive Manufacturing.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

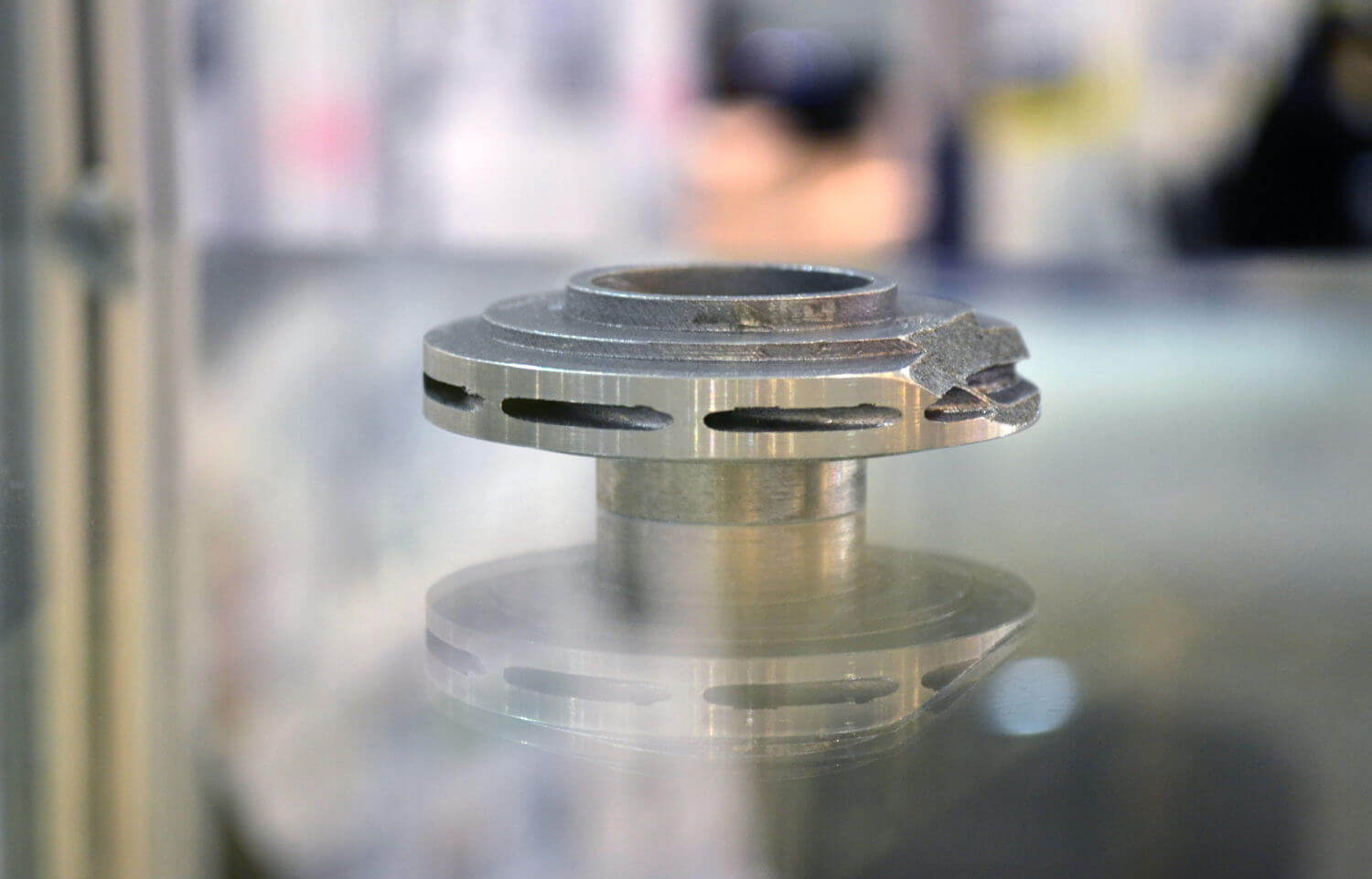

Featured image shows metal parts inspected with Sigma Labs software. Photo via Sigma Labs.