The UK CEO of Siemens, Europe’s largest industrial manufacturing company, has officially opened a £24 million research facility at the University of Nottingham (UoN) to accelerate advanced manufacturing technologies.

With a total research portfolio of £80 million, the Advanced Manufacturing Building (AMB) will support the UK’s manufacturing industry by developing new processes involving additive manufacturing, bioengineering, and Operations Management (OM) and Information Systems (IS).

“This new facility heralds the start of something truly special for Nottingham, and will help place the region and indeed the country at the cutting edge of digital manufacturing,” said Juergen Maier, Chief Executive of Siemens UK, upon opening the AMB as a guest of honor.

“Why is this important? It’s important because our future lies in driving a new technological revolution focusing on AI, automation, robotics, and 3D printing as well as many other new exciting technologies. It will ensure graduates are at the cutting edge and ready to take up the high productivity, high wage jobs of the future.”

The Advanced Manufacturing Building

Financed through the through the Local Growth Fund, the AMB houses UoN’s Institute for Advanced Manufacturing (IfAM), a facility measuring approximately 9000 square meters. The IfAM encompasses a multidisciplinary team of academics in the UK, Malaysia, and China.

Support for the AMB follows the recent establishment of Siemens’ £27 million 3D printing facility in Worcester, UK.

“Skills challenges remain a key issue for many manufacturing businesses in the UK, due to factors such as the fast pace of technology development, an aging workforce and a shortage of graduates with relevant multidisciplinary skills and experience,” explained Professor Svetan Ratchev, Director of the IfAM.

“The Institute is helping to shape the manufacturing research agenda nationally and internationally and is supplying the technology and specialist skills to support key industrial sectors and encourage the growth of emerging industries.”

In addition, the AMB houses the Rolls-Royce University Technology Centre in Manufacturing and On-Wing Technology which is working with the UoN on a new range of robot ‘mechanics’ for jet engine maintenance.

Moreover, other areas of research focus at the AMB include advanced materials, drug delivery and tissue engineering, food sciences, human factors, machining and condition monitoring, metrology, process and environmental technologies, and human-machine interactions.

Also located in the AMB is the Centre for Additive Manufacturing (CfAM) at the University of Nottingham. Richard Hague is the Director of CfAM and states, “We are a national centre for Additive Manufacturing research – the group’s been going for around 25 years and currently we have over £20M of funded research ongoing (both governmental and industrial), where we have a fabulous lab with over £10M worth of equipment in it, all housed in the new building.”

“The group is over 100 people and we work internationally with other labs around the world (such as Lawrence Livermore National Labs in the US) and so it’s not an insignificant activity on the world stage.”

The University of Nottingham & additive manufacturing

In addition to the AMB, several other additive manufacturing innovations have sprung from UoN in the past few years. The University previously collaborated with University College London (UCL) to improve human brain mapping with a 3D printed magnetoencephalography (MEG) helmet. Also, UoN researchers developed a 3D printable smart material with a novel way of storing information.

Jake Berry, Member of Parliament for Rossendale and Darwen and Minister for the Northern Powerhouse proposal, commented on the establishment of the AMB:

“Our £5 million investment in the University of Nottingham’s new Advanced Manufacturing Building through the Local Growth Fund shows our modern Industrial Strategy in action.”

“This state-of-the-art facility will benefit Nottingham, the Midlands, and the whole UK economy by driving innovation, equipping people to secure highly skilled jobs and supporting manufacturing businesses of all sizes to thrive.”

Submit your nominations for the 2019 3D Printing Industry Awards here.

Also, for all the latest 3D printing news, subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Make your next additive manufacturing career move or hire new talent. Search and post 3D Printing Jobs on our free jobs service.

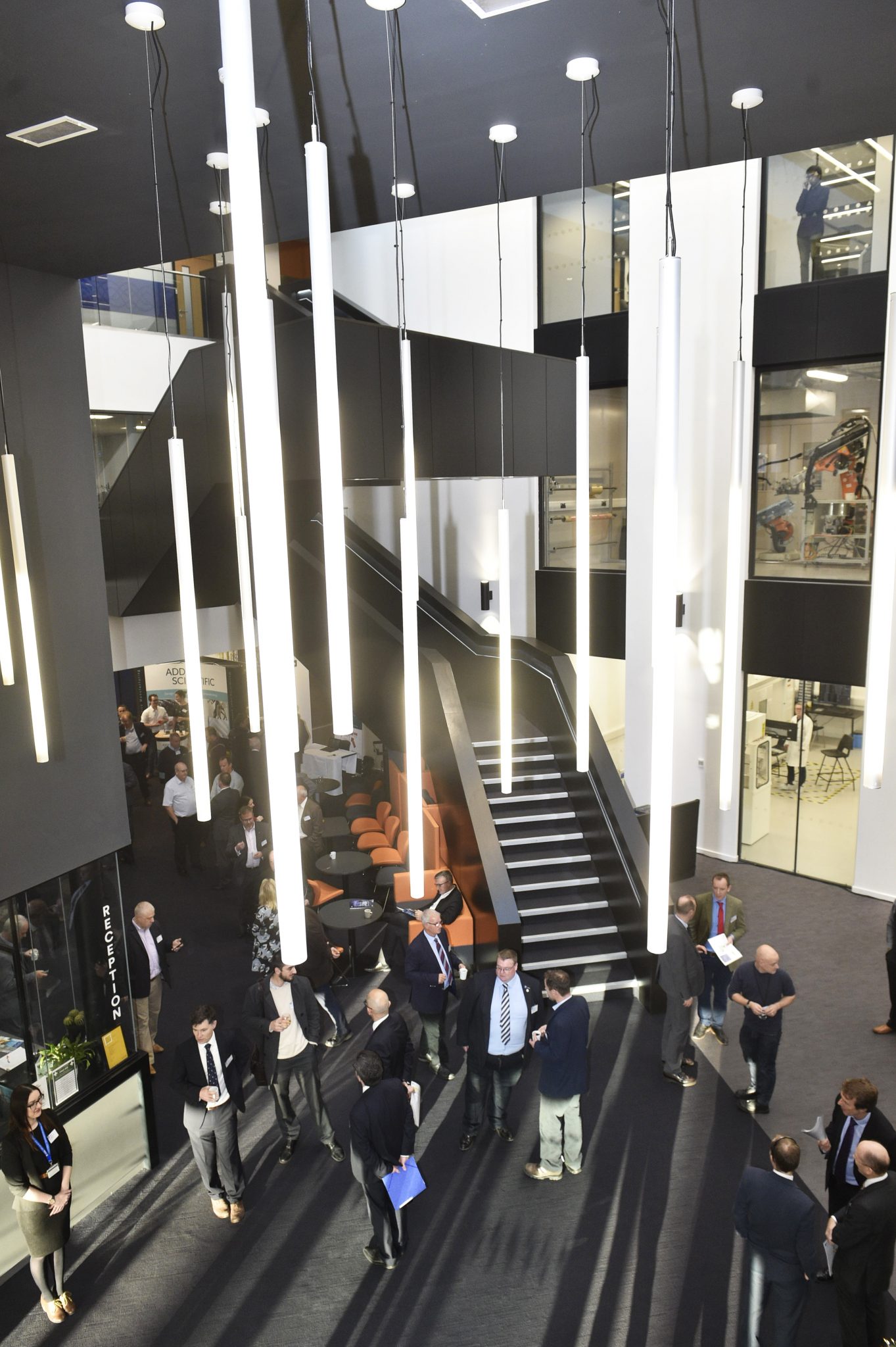

Featured image shows a researcher in the Nottingham Advanced Robotics Laboratory housed in the AMB. Photo via the University of Nottingham.