Industrial manufacturing firm Siemens has today opened its Advance Manufacturing Transformation Center (AMTC) in the western part of Singapore in Tuas, a one-stop advanced manufacturing ecosystem facilitating the transition into 3D printing and Industry 4.0.

Deemed a first-of-its-kind competence center, the 800 square metre AMTC is composed of three elements; a Digital Enterprise Experience Centre (DEX), Additive Manufacturing Experience Center (AMEC), and Rental Labs.

“The AMTC was set up to bridge the gap between prototyping and industrial production of additive manufacturing to support and guide our companies on the journey towards digital transformation,” said Benjamin Moey, vice president of Siemens AMTC Asia-specific. “The vision for AMTC is to celebrate the adoption of advance technologies, simplification, digitalization, and collaboration, in an ecosystem of key partners.”

The AMTC

Providing manufacturing design consulting, the DEX aspect of the AMTC showcases digital enterprise solutions which allow companies to envisage their advance manufacturing plants with the creation of a digital ‘twin’. Through this, firms can simulate, optimize, and evaluate potential manufacturing operations before construction takes place.

“We design the product virtually, test it virtually, and then when the mechanics are optimized we then bring it into the real world and print it in a 3D printing environment,” explained Raymond Klein, head of Digital Industries ASEAN Siemens. “We can take the digital twin and simulate, for example, an overhauled complete production line to be upgraded to enable 3D printing. We can assess the productive output optimization and so on, and with this, we enforce the real-world to follow because we have the tender specification already created in the virtual world.”

The second element of Siemens’ new AMTC is the AMEC, where companies can experience hands-on exposure to an end-to-end additive manufacturing production line, supported by AMTC’s ecosystem of technology partners. According to Klein, this brings additive manufacturing R&D together with commercialization by enabling companies to carry out prototyping with the support of on-site additive manufacturing experts.

Thirdly, the Rental Labs aspect of the AMTC provides affordable access to high-end industrial design software and 3D printers, as well as post-processing equipment, for companies interested in low-volume 3D printing for prototyping and testing, before deciding to invest in their own additive manufacturing production lines.

“Where the return on investment is not given to invest in a huge production line, and as long as our partners have spare parts or our customers come here and design the parts, these companies can rent time on the 3D printer and print their products during the night, aided by our employees here in the center,” Klein said.

The founding partners of the AMTC, who equally share the environment with Siemens, include The Singapore Agency for Science, Technology and Research (A*STAR), EOS, Georg Fischer (+GF+), hp, Singapore Polytechnic, Technical University of Munich, and Ultimaker, among others.

“Each partner brings a critical part to the ecosystem providing a niche expertise along this line,” added Moey. “From research academic institutions providing R&D and training capabilities to advance manufacturing providers such as industrial 3D printers and post-processing equipment, to certification bodies. Together we form this truly unique platform for companies and their staff to learn, understand, and adopt additive manufacturing technologies, with the support of our community of experts.”

Congratulations to our @siemensindustry team in Singapore on the opening of the new Advance Manufacturing Transformation Center! It will enable @SiemensSEA to bring specialist expertise for the #automation& #digitalization of factories to the ASEAN region. https://t.co/6ofP8QIywx pic.twitter.com/kIk6OsmVro

— Klaus Helmrich (@KlausHelmrich) September 10, 2020

Above – Klaus Helmrich, member of the managing board of Siemens AG and Digital Industries CEO, congratulates the Siemens team on the launch of the AMTC center.

Additive manufacturing in Singapore

Since 2011, Singapore has invested over 200 million Singapore dollars to support research and ecosystem development in additive manufacturing. The country’s National Additive Manufacturing Innovation Cluster (NAMIC) has grown to become a key enabler in driving industry adoption and commercialization of advanced technologies.

Back in 2018, NAMIC became a strategic partner of global standards leader ASTM International‘s Additive Manufacturing Center of Excellence. This year, NAMIC, the Maritime and Port Authority of Singapore (MPA), and Singapore Ship Association (SSA) announced Phase 2 of their Joint Industry Programme (JIP) to implement additive manufacturing in the marine industry.

A few months prior, HP, the Nanyang Technological University (NTU Singapore), and the National Research Foundation Singapore (NRF) officially opened the HP-NTU Digital Manufacturing Corporate Lab with 3D printing technologies.

Most recently, energy giant Royal Dutch Shell announced a four-year pilot project at its Pulau Bukom refinery in Singapore to also trial ‘Digital Twin’ technology, expected to be fully implemented in 2024.

Adapting to Industry 4.0 and advanced technologies

During the virtual launch event for the center, a panel of speakers discussed the wider applications of, and forecasts for, the adoption of 3D printing technologies and Industry 4.0 both in the ASEAN market and further afield.

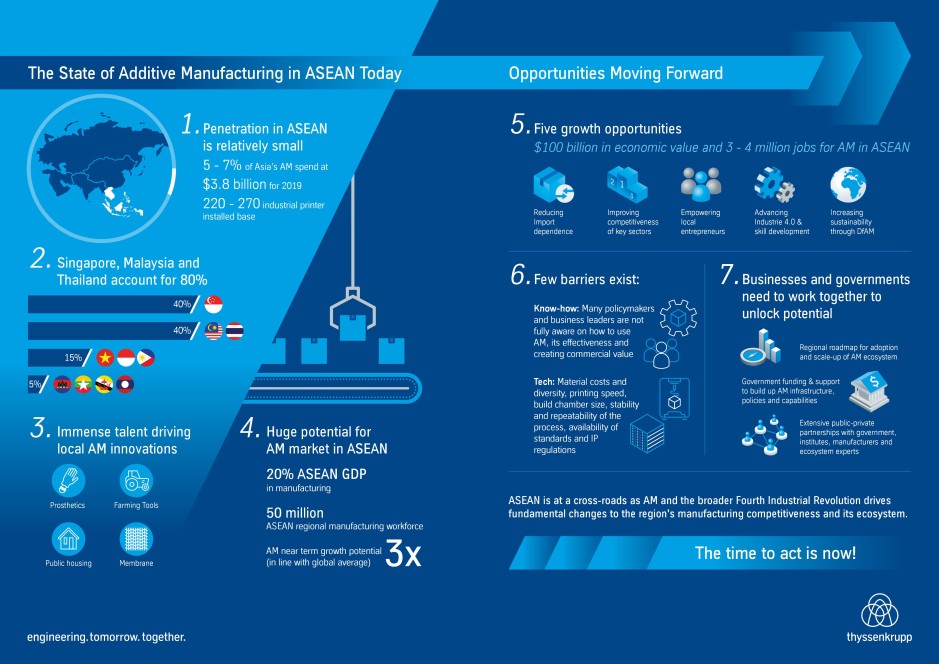

German multinational engineering group thyssenkrupp has predicted that by 2025 the ASEAN additive manufacturing industry will generate an incremental value of $100 billion.

Panelist Terrence Oh, senior vice president of EOS, also believes there will be a ‘tremendous growth’ of additive manufacturing in the ASEAN region, and predicted a bright future ahead for Southeast Asia in this field.

“If I look across Asia, the industries that are adopting this are mainly led by the aerospace and defense industry, as well as the medical and healthcare industry,” he said. “In the next tier down, the energy and automotive sectors have also started using the technology for manufacturing. With these industries leading the way, many others will follow suit.”

Moey agreed with him, also stating that the Covid-19 pandemic had accelerated the need for digitalization for these industries: “Beyond trying to get supply chains reactivated, companies need to be self-sufficient and able to manufacture their own parts in-house,” he said. “The Covid pandemic has shown the resilience of how we have learned to innovate, and has brought to the fore the need for automation, digitalization, and the Internet of Things to bring us closer to being self-sufficient.”

The panelists also discussed the predicted dependence on robots and Artificial Intelligence (AI) in the coming years, married with the building of a mass of critical experts to maintain and develop this aspect of digitalization. Sustainability and the environmental positives additive manufacturing technologies provide are also expected to become key driving forces in adopting advanced technologies.

Open for business

The AMTC is officially open, deemed an ‘open place’ based on multiplying the knowledge of the founding partner companies and passing it on to their customers and visitors to the center. The center will act not only as a platform for manufacturing companies but also as a place where Siemens and other partners can work with machine builders to help enhance and develop their capabilities, both from overseas and within Singapore. Central to the creation of the center is the aim to further establish Singapore as a hub for advanced manufacturing within both the ASEAN and global markets.

“Our diverse manufacturing base represents sophisticated demand for advance manufacturing technologies in sectors such as electronics, healthcare, and biopharmaceuticals, which are doing well in the current pandemic,” said Lim Kok Kiang, executive vice president of the Singapore Economic Development Board. “I also believe for other industries that this will increasingly become an important element as the industries start the journey towards digitalization. The AMTC investment by Siemens is, therefore, a very timely investment and reflects the company’s confidence in the long-term prospects of ASEAN and Singapore’s location.”

Nominations for the 2020 3D Printing Industry Awards are still open, let us know who is leading the industry now.

The fourth edition of the 3D Printing Industry Awards Trophy Design Competition is now underway. Enter your design for the chance to win a CraftBot Flow 3D printer.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Lim Kok Kiang, executive vice president of the Singapore Economic Development Board, (centre-left) and Raymond Klein, head of Digital Industries ASEAN Siemens, declare the AMTC officially open. Image via Siemens virtual launch.