We are living in amazing times where what used to be science fiction is now just science and the stuff of legends is becoming real. Although still in its infancy, 3D printing is giving us the power to shape reality, thus making certain myths a little less impossible. For example, since the holiday season is approaching, Santa Klaus. Two things make his myth unlikely: delivering gifts to everyone in the world in one night and being able to produce every single gift in a small lab at the North Pole. While no advance in technology – not even drones – could soon help him out with the first one, the second one is starting to look very much like a Shapeways Factory.

I got to visit the factory in Long Island City, Queens, (NY), just as the Dutch-American company is getting ready for the holiday rush. Shapeways just launched the Holiday Gift Guide, which gives customers 50% off shipping costs and a large choice of consumer-created consumer-focused original accessories and gift ideas. For one of those now recurrent coincidences, I got in touch with Mansee Muzumdar, from Shapeways PR department, who told me they were organizing an open house tour, just as I was staying in New York for a few days.

Shapeways Global Community Manager, Savannah Peterson, took us around to see the first “Santa Shapeways” little helpers: a team of designers who receive the 3D files and set up the 3D prints in the 3D planning area. This means they have to optimize the print plate for maximum efficiency, especially when working with the extra large EOS P760.

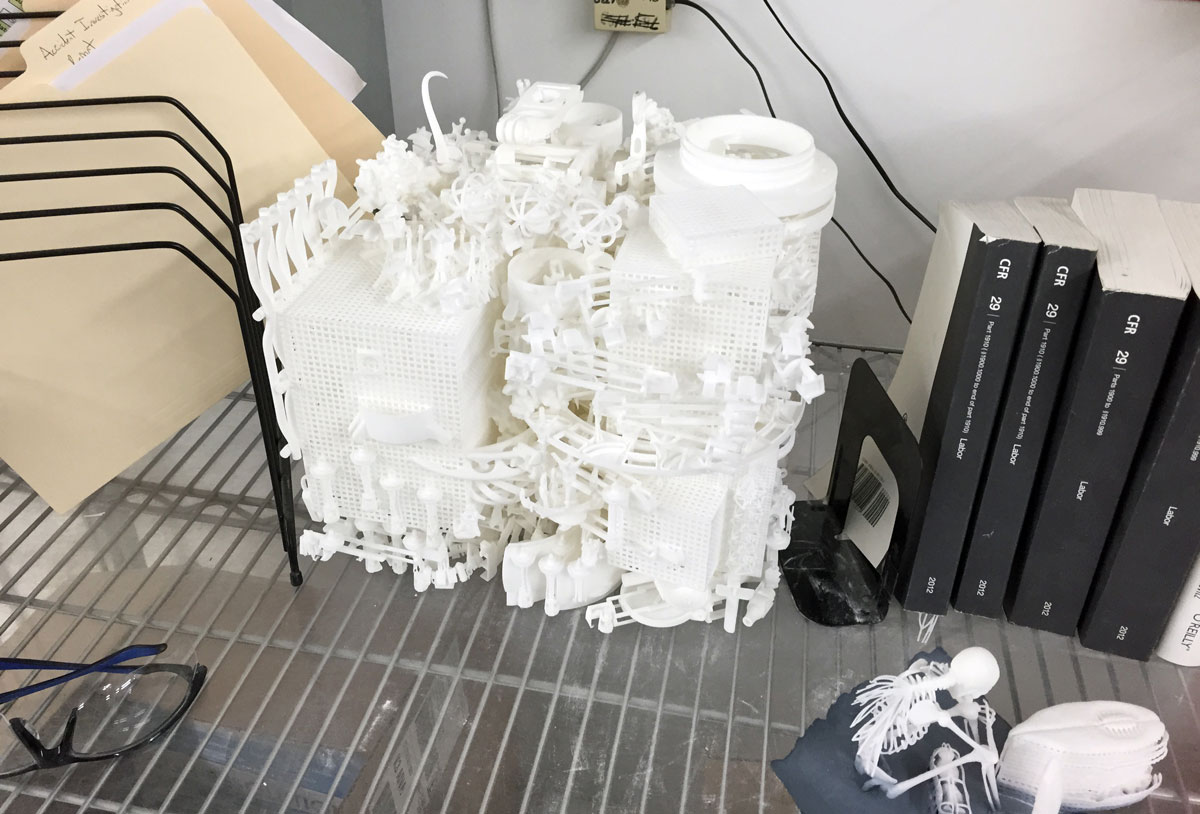

These machines give Shapeways very large print volumes to work with, which means the planning work has to be extremely accurate to avoid running into errors that could ruin an entire print job and thus literally hundreds of laser sintered objects (such as in the artistic “blob” in the photo above).

Shapeways’ primary production technology is plastic SLS. The main area of the factory holds seven EOS laser sintering systems that are working constantly. These are the machines that make it possible for “Santa” to create almost anything but the process is not as automatic as most of us usually imagine. A lot more work goes into the products once they come out of the machine — the often forgotten post-processing.

Laser sintering does not require supports – and that is a big advantage – however when the print plate is extracted it looks like a very large block of… snow. Shapeways’ “helpers” to keep the analogy going, have to painstakingly remove the excess powder, paying attention not to break or damage or lose the 3D printed items within it. Most of the powder is then filtered and up to 60% of it is recycled for the next production run.

Although the primary technology in terms of cost efficiency is SLS, Shapeways does offer a variety of other technologies as well, including high end MJP and Wax 3D printing through 3D Systems market leading 3500 HD Max machines, or full color gypsum and plastic CJP (Color Jet Printing) also by 3D Systems. FDM is provided through Stratasys’ Fortus technology and all metal is done though external partners as lost wax casting of 3D wax models, with ExOne in Pittsburgh as main partner for metal manufacturing.

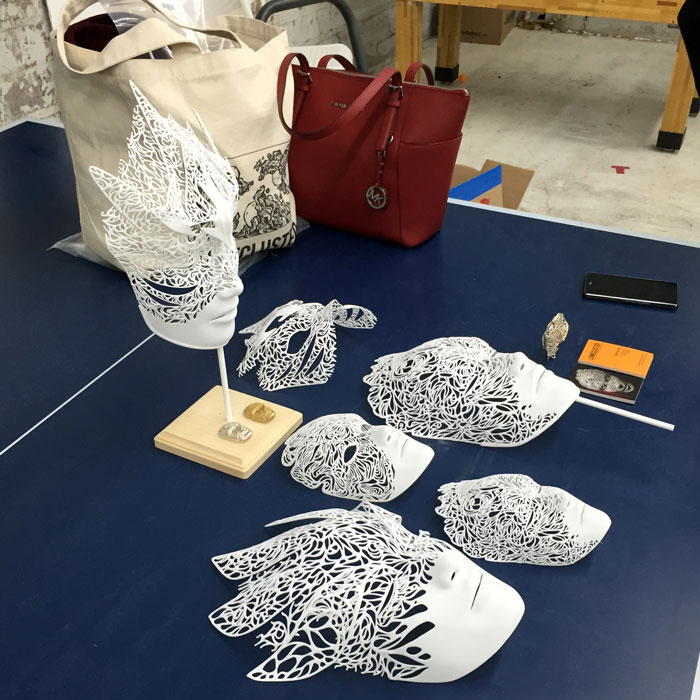

Once all the items are finished and colored they are to be sorted out and shipped off. Each hello tray in the photo above contains different products from hundreds of different designers throughout the US. There were a few present for the occasion, some that I had the opportunity to write about in the past and it was great to get to meet personally. For example Paul Liaw and Susan Taing from B-hold, as well as some I had not met yet such as Shapeways customer service agent turned designer Andrew Thomas and Melissa Ng from Lumecluster.

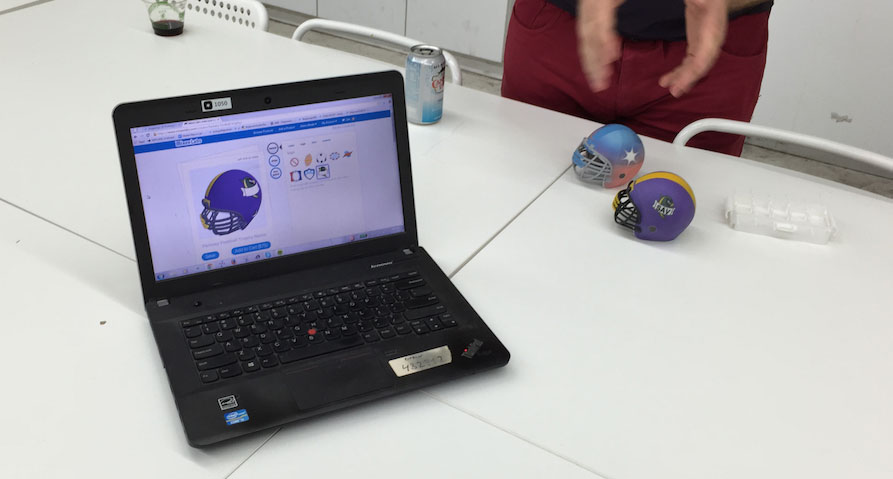

Perhaps Santa Klaus still has a little bit of a lead on Shapeways in terms of global reach but I am not so sure his own elves can compete much longer in terms of product customization. Tell that to the kid asking for a custom made Football helmet with his own design logo on it.