Metal 3D printing start-up Seurat Technologies has raised another $21 million to help accelerate the roll-out of its proprietary Area Printing technology.

Supported by new investors Xerox Ventures and SIP Global Partners, as well as long-term backers True Ventures, Porsche Automobil Holding SE, Maniv Mobility and Capricorn’s Technology Impact Fund (TIF), the extension to Seurat Technologies’ Series B financing round of June 2021 takes its total raised to $79 million.

Using its newfound capital, the company aims to further expand its leadership team, as well as ramp-up the manufacture of its upcoming Area Printing machines, as it builds towards its first commercial launch later this year.

“Seurat’s mission is to make manufacturing better in every way by embracing the agility and design freedom of 3D printing, but not at the same expense,” said James DeMuth, CEO of Seurat. “We are working with the world’s largest manufacturers in migrating their designs to Area Printing to help them gain lead-time, cost, and quality advantages, while making a positive environmental impact.”

“Area Printing decouples resolution and speed, which is the secret sauce to making 3D printing a high-volume process.”

What is Area Printing technology?

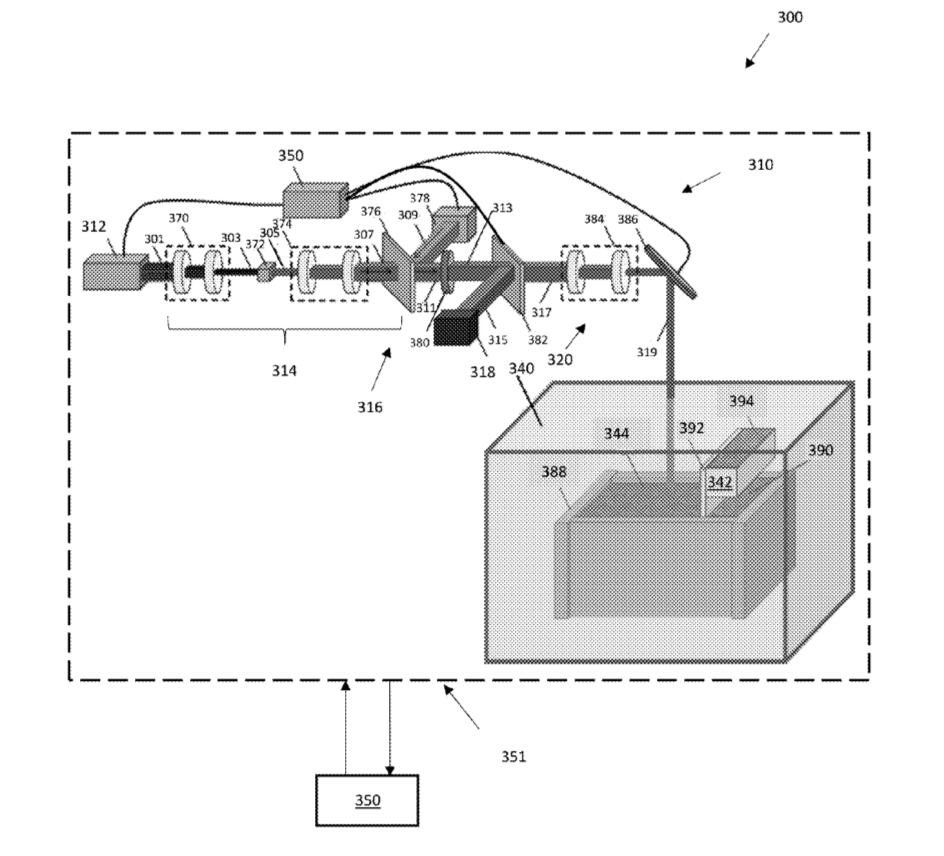

First honed at Lawrence Livermore National Laboratory, ‘Area Printing’ essentially describes a process in which a laser containing over 2.3 million pixels, is used to ‘micro-weld’ metal powders into thin layers on a print bed. According to Seurat Technologies, its approach is unique, as it ‘decouples’ print rate and resolution, allowing it to overcome 3D printing’s “speed, quality, scale and cost trade-offs.”

Although Seurat Technologies has yet to introduce a commercial portfolio as such, it says that its soon-to-be-released system will offer users major speed and cost efficiency benefits, especially compared to traditional production methods. At launch, the machine is set to be capable of 3D printing at a cost of $300/kg, but the firm intends to lower this to $150/kg by 2025, giving it casting-level capabilities.

In practise, the process is said to have various applications too, and Seurat Technologies claims that it has now secured seven letters of intent to join its commercialization program from “the world’s largest automotive, aerospace, energy, consumer electronics and industrial companies,” as it seeks to bring its patented technology to market for the first time.

Seurat’s $21M marketing plans

Seurat Technologies’ latest round of funding has seen it attract the backing of SIP Global Partners and Xerox Ventures, two serial investors in advanced technologies. While the former tends to target young firms poised for growth in Asian markets, the latter has set its stall out to “invest in early and growth-stage start-ups,” particularly those developing eco-friendly manufacturing technologies.

Xerox Ventures is also a subsidiary of the wider Xerox corporation, which itself introduced its first 3D printer, the ‘ElemX,’ in February 2021. As a result, the firm’s investment in Seurat Technologies could be seen as a fresh commitment on behalf of its parent company to the additive manufacturing sector, although Xerox Ventures’ Tim Chiang says the move is consistent with its long-term goals.

“Xerox Ventures is investing in high growth start-ups that usher forth truly transformative business solutions,” explained Chiang. “We believe that the future of how we make products will solve today’s supply chain and sustainability challenges, and Seurat will help make that future a reality for mass-production with their breakthrough advanced manufacturing technology.”

Leveraging the $21 million raised via its funding round extension, Seurat Technologies now aims to continue growing its team, having almost doubled its headcount in 2021, while hiring Anthony Di Paola as its CFO, Joyce Yeung as its Senior Director of Marketing, John Rushton as its Director of Market Development and Amy Donahue as its Controller.

The company has also committed some of this capital to fund the manufacture of its first production-grade system, a machine that it believes will have strong eco-credentials. Citing EPA figures showing that the manufacturing sector is responsible for 22% of US greenhouse gas emissions, the firm says that its upcoming unit will help “reduce harmful environmental pollutants when operating at full capacity.”

“We strongly believe that the team, its technology and its industry partners, represent a unique opportunity to create a vastly more efficient and sustainable global manufacturing ecosystem,” added Jeffrey Smith, General Partner at SIP Global Partners. “We are exceptionally excited to join Seurat in its mission to reinvent precision manufacturing at scale.”

Accessible metal 3D printing efforts

When Seurat Technologies does bring its new machine to market, it will face stiff competition from a number of better-established high-throughput metal 3D printing firms. Using its wire-fed Electron Beam Additive Manufacturing (EBAM) systems, for instance, Sciaky was able to deposit a record-breaking 12,000 lbs of titanium in 2020 alone.

On the cost efficiency front, new competitors such as ValCUN have also sought to make metal 3D printing more accessible, with the firm raising funding towards the R&D of an energy-saving metal system last year. Set to be fitted with a unique heating input that’s capable of processing feedstocks more efficiently, the machine could have automotive, robotics or energy applications, once finished.

Xact Metal, meanwhile, has already lowered the cost of entry to metal 3D printing with its economical new ‘XM’ portfolio. Launched in late-2021, the firm’s XM200C and XM200G machines are designed to provide SMEs with a more affordable means of adopting powder bed fusion, and reaping the benefits of industrial-grade printing.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a Seurat Technologies metal 3D printed part. Image via Seurat Technologies.