In recent years the U.S. Navy has demonstrated its commitment to promoting 3D printing throughout its ranks. 3D printers have been introduced to sea and air maintenance units across the country, and R&D efforts have resulted in Marines projects such as the expeditionary fabrication laboratory (X-FAB), and combat zone drones.

Now, the U.S. Navy’s Office of Naval Research (ONR) has partnered with additive manufacturing data collection and software development company Senvol. The purpose of the partnership is to make a data-driven machine learning computer program for 3D printed parts.

Locally, the Naval Surface Warfare Center Dahlgren Division (NSWCDD) has partnered with the University of Virginia (UVA) to gain an impactful understanding of capabilities and limitations in additive manufacturing.

No longer trial and error

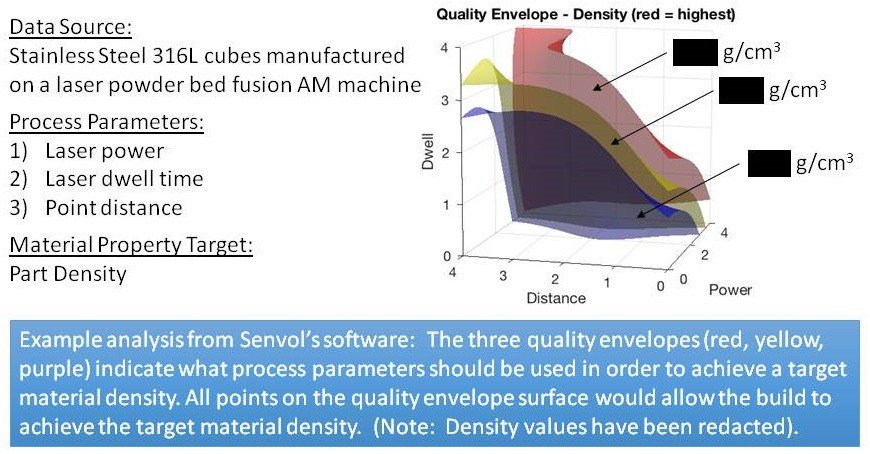

Launched in 2015, Senvol, which is partnered with America Makes, has curated an extensive database of over 1,400 additive manufacturing machines and materials. By using this data, the ONR aims to create a program that will expedite the additive material and design characterization process, reducing the amount of trial and error currently required to make specific components.

Annie Wang, President of Senvol, comments, “Our software’s capabilities will allow ONR to select the appropriate process parameters on a particular additive manufacturing machine given a target mechanical performance.”

For the company, that partnership presents “a unique opportunity” to save the ONR a great deal of time and money. Computer vision will also be part of the project, enabling the identification of irregularities in a build and the resulting flaws it can cause.

Wang concludes, “We are very excited about our work with the Navy’s Office of Naval Research.”

UVA steels itself with Navy alloy partnership

Cementing a collaboration with UVA, the Navy’s NSWCDD has confirmed that it will continue to work with the university to understand the benefits of 3D printable alloys.

Employing approximately 5,700 scientists & engineers the NSWCDD undertakes high profile research and development projects across computer, mechanical, bio and systems engineering.

Collaboration with UVA is also part of an Educational Partnership Agreement that will help graduates seek employment. Dr. Tabitha Apple Newman, NSWCDD engineer UVA mentor, comments “We look forward to continuing and expanding upon the benefits afforded to the Navy, university, faculty and students involved,”

“Additive manufacturing research, in particular, reaches across technical fields and capabilities, and allows Dahlgren (the NSWCDD) to immediately better evaluate and design products for its customers – whether for gun prototypes, special-use technologies, CBR (chemical, biological and radiological) defense, or electric weapons.”

For all the latest 3D printing news – subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

3D Printing Industry Jobs is live. Post a job or discover your next career move now.

Protolabs is sponsoring the 2018 3D Printing Industry Awards design competition.Submit your entries now with the chance of winning a 3D printer.

Featured image shows U.S. and Japanese naval ships in a MultiSail exercise in the Philippine Sea. U.S. Navy photo by Mass Communication Specialist 3rd Class Sarah Myers/Released.