Researchers from the Khalifa University of Science and Technology in Abu Dhabi are investigating the 3D printing of multifunctional optical fibers.

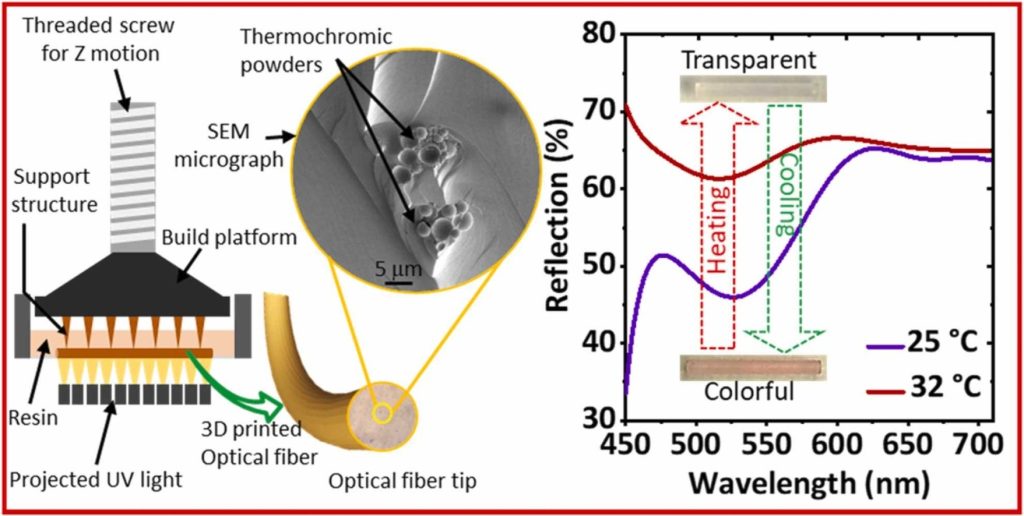

Using polymer-based stereolithography (SLA) technology, the team 3D printed a set of optical fiber designs and integrated thermochromic micro-powder pigments, making them responsive to changes in temperature. At the same time, owing to the optical properties of the fibers, the researchers also managed to endow their designs with strain sensing capabilities.

By exhibiting sensitivity to two stimuli simultaneously, the 2-in-1 optical fibers show great promise in biomedical and healthcare applications for remote temperature and strain sensing devices.

The research paper writes, “This work may pave the way towards developing tunable thermochromic sensors that are cost-effective, reusable, and flexible.”

Additive manufacturing for sensing applications

The list of temperature sensor use cases is a long one, including medical diagnostic applications, power generators, and even consumer electronics. Temperature sensing is typically done using electrical sensors, but these sensors often see performance degradation in harsh conditions and are impacted by magnetic and electrical fields.

A potential sensing alternative can be found in optical fibers, as these are much more resilient in harsher conditions and aren’t thrown off by electromagnetic waves. Conventional glass-based optical fibers can be manufactured to be lightweight, flexible, and highly compact, while polymer-based variants also have the added benefit of robustness.

While polymer fiber sensors are usually produced via molding or drawing processes, there’s also the option to 3D print them for further customization. Beyond just geometric tunability, it’s possible to integrate stimuli-responsive materials into resins to create functionalized composites that exhibit sensitivity to a wide variety of factors. This makes it possible to 3D print sensors that detect electromagnetic fields, light, temperature, and even acidity.

Integrating thermochromic micro-powders

In the present study, the Khalifa researchers mixed a variety of colored, thermochromic micro-powders into a photocurable resin and used the composites to 3D print temperature-sensing optical fibers. The powder range comprised red, blue, and green pigments, as well as a combination of red and blue.

To evaluate the performance of the 3D printed sensors, they characterized their optical properties in a temperature range of 25 – 32°C. The team also tested how the bending angle of the fibers affected their ability to transmit light, demonstrating their viability as strain sensors.

Thermal and strain sensing characterization was completed using a variety of characterization techniques such as optical microscopy, scanning electron microscopy (SEM), UV-visible spectrophotometry, X-ray diffractometry, and uniaxial tensile machine testing.

Looking at the results, the addition of thermochromic powders decreased the strength of the 3D printed optical fibers. A transparent control sample offered the highest strength and elastic modulus, while the red-blue combination delivered the least strength and elasticity.

However, each of the pigment samples featured distinguishable colors at 25°C room temperature, while they all became transparent when heated to 32°C. The effect was completely reversed when the fibers were cooled back to room temperature, demonstrating a linear relationship between temperature and reflection intensity. This ultimately means the printed fibers could indeed feasibly be used for accurate temperature measurements.

Similarly, the light intensity of the fibers was slashed significantly when they were bent, showcasing how they could also be used in strain sensing applications such as deformation and structural failure prediction.

Further details of the study can be found in the paper titled ‘3D printed polymer composite optical fiber for sensing applications’.

The 3D printing of optical devices isn’t limited to fibers either. Researchers at the US Department of Defense-backed MIT Lincoln Laboratory recently came up with a novel low-temperature approach to 3D printing full-scale glass objects. The technique can even be tuned to print a wide variety of inorganic glasses with embedded functional nanomaterials for dielectric, metallic, and optical properties.

Elsewhere, researchers at the University of Freiburg, together with colleagues at the University of California, Berkeley, recently developed a means of rapidly 3D printing complex glassomer parts at a microscopic scale. Known as ‘Microscale Computed Axial Lithography’ (Micro-CAL), the approach involves curing resin at several angles at once, triggering polymerization in the overlap zones.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Khalifa University campus. Photo via Khalifa University of Science and Technology.