Researchers at Khalifa University have come up with a set of 3D printed glasses that could be capable of curing Color Vision Deficiency (CVD) disorders.

Composed of tinted lenses housed in MSLA 3D printed frames, the team’s eyewear effectively works by blocking out undesired wavelengths while staying transparent to the rest of the visible light spectrum.

Already, CVD-affected volunteers wearing the glasses have reported significant improvements in color identification, leading the scientists to conclude that their glasses “have great potential in combating color blindness.”

Developing a color blindness cure

CVD (also known as color blindness), is a common congenital disorder that limits the ability of patients to distinguish between shades of certain colors. According to the charity Colour Blind Awareness, as many as 1 in 12 of men (8%) and 1 in 200 women suffer from CVD. The disorder, which makes daily tasks like identifying the color of traffic lights or fresh foods very difficult, is caused by defective photoreceptor ‘cone’ cells in the retinas of affected patients’ eyes.

In healthy eyes, blue, red, and green cone cells function together to allow for the detection of primary colors. Color blindness is caused when one of these cell types is faulty or missing. While gene therapies are currently under development, these remain at the lab testing stage, meaning that patients are left needing glasses or contacts to alter their color perception.

Firms like Enchroma have offered such eyewear since 2012, and it says its glasses are highly-effective, but it remains difficult to customize these for patients. With this in mind, the Khalifa researchers have turned to 3D printing to develop frames of their own, which can be tailored to users’ color-correcting needs.

Putting color correction to the test

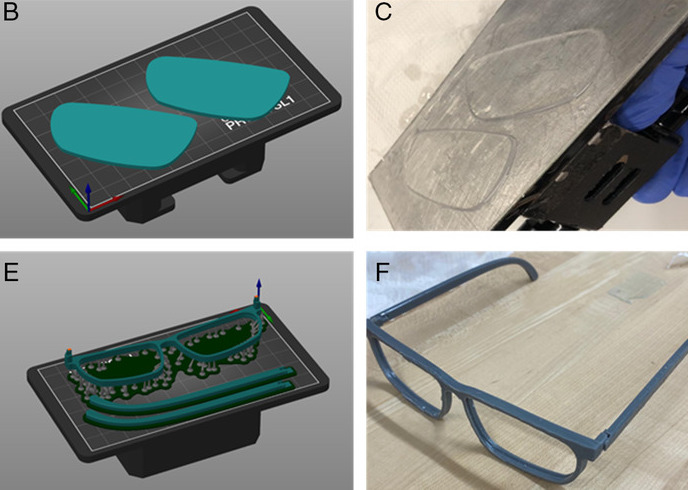

Once the scientists had designed a prototype pair of glasses on SOLIDWORKS, they printed them from ASIGA DentaClear and Gray resin on a Prusa SL1S system. In the process, the team found that curing time and layer thickness were vital to achieving optimized optical and mechanical properties, with a six-second per layer print time and 25-micron thickness proving ideal.

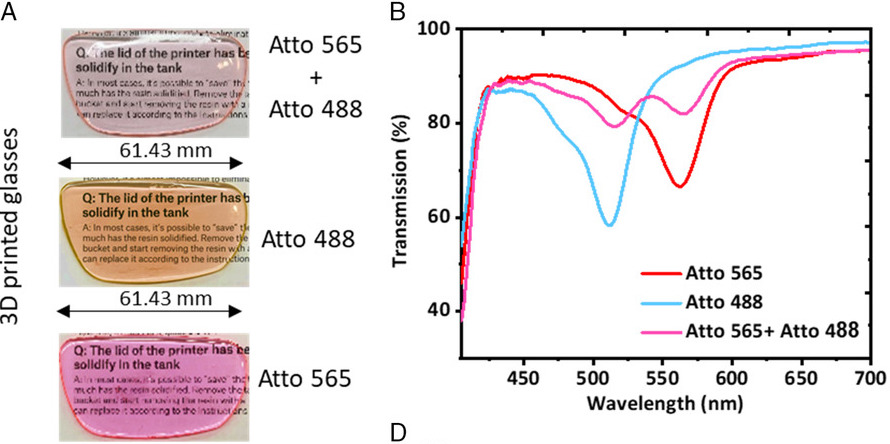

To create the glasses’ lenses, the researchers combined their resin with Atto 565 and Atto 488 wavelength-filtering dyes, which gave them the desired tinting effect. When fitted to frames and ready for testing, these lenses proved capable of working as desired during characterization, in that they blocked undesired wavelengths for CVD patients between 480–510nm and 550–580 nm.

Compared to off-the-shelf Enchroma glasses, the 3D printed glasses were also found to filter out light at similar wavelengths while showing “better selectivity” in the light they transmitted. In practice, this meant the 3D printed eyewear was capable of blocking out more than 50% of undesired wavelengths but maintaining transparency of over 85% to other light on the visible spectrum.

With volunteers later using the glasses to achieve 45% and 200% improvements in color identification during the standard Ishihara color blindness test, the team says their 3D printed frames represent a viable alternative treatment for CVD patients that’s more customizable and effective than commercial eyewear.

“Results indicated that our 3D printed glasses were more selective in filtering undesired wavelengths than commercially available CVD glasses,” concluded the team in their paper. “[Our] Findings show that these 3D printed tinted glasses have great potential in combating color blindness, owing to their ease of fabrication and customization, which can be tailored to the patient’s need.”

Interestingly, the Khalifa team’s 3D printed glasses aren’t the first to be developed using the technology to address vision disorders. Earlier this year, researchers at the Technical University of Munich (TUM) developed 3D printed haptic feedback glasses that allow people with visual impairments to navigate without a cane.

Elsewhere, additive manufacturing continues to make inroads into the conventional eyewear market. Optiswiss installed Luxexcel’s VisionPlatform 7 platform late last year, designed to allow it to better address glasses manufacturers with 3D printed lenses. Looking at YOU MAWO 3D printed frames, the EOS customer found in a 2021 life cycle analysis that using 3D printing reduced their carbon footprint by as much as 58%.

The researchers’ findings are detailed in their paper titled “Development of 3D-Printed Glasses for Color Vision Deficiency,” co-authored by Fahad Alam, Ahmed E. Salih, Mohamed Elsherif and Haider Butt.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? featuring discussion, debriefs, video shorts and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Khalifa team’s 3D printed glasses. Image via Khalifa University.