The nominations for the 2021 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Scientists from the Eindhoven University of Technology (TUE) have broken new ground with the development of a novel color-changing liquid crystal ink that is compatible with 3D printing technology.

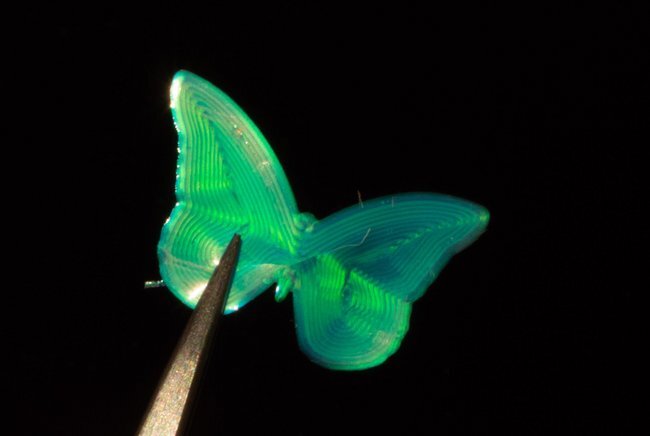

The nature-inspired liquid crystal ink can be printed onto surfaces using direct ink writing, a form of extremely precise extrusion-based 3D printing. Until now, it’s been extremely difficult to print such materials into complex structures and devices, so the team believes its work could have major implications for applications such as decorative lighting, soft wearable sensors for health monitoring, and even augmented reality optics.

Jeroen Sol, lead author of the study, states, “DIW is an extrusion-based 3D printing approach where an ink is dispensed from a small nozzle onto a surface on a layer-by-layer basis. Current cholesteric liquid crystal inks cannot be printed with DIW, so we created a liquid crystal ink compatible with DIW.”

Cholesteric liquid crystals

Out in nature, materials that change colors based on the angle they’re viewed at are called iridescent materials. Prime examples are certain butterfly wings, the exteriors of jewel beetles, and a material known as nacre (aka mother of pearl), which is found on the inside of mollusks’ shells.

We also have a man-made alternative to these materials called cholesteric liquid crystal, a material that exhibits the properties of both liquid and solid crystals. Cholesteric liquid crystals, as well as being used in LCDs, have advanced applications as smart materials in light reflectors, switchable windows, and even solar panels.

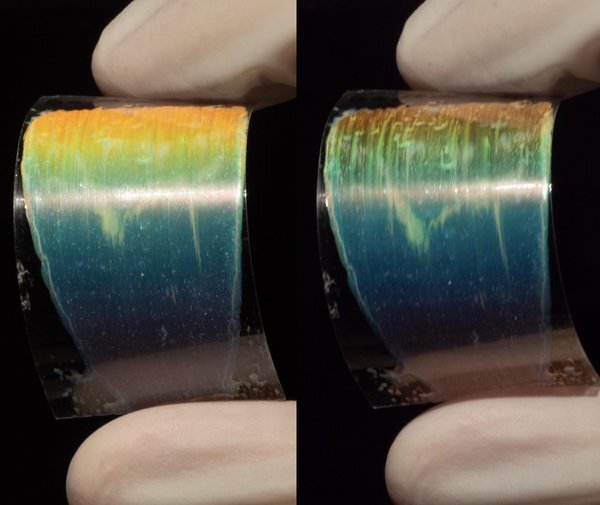

Unfortunately, cholesteric liquid crystals aren’t viscous enough to craft into solid structures, so it’s so far been impossible to use them with advanced manufacturing processes like 3D printing, limiting their applications somewhat. The TUE researchers have jumped this hurdle with the development of a custom light-reflective liquid crystal ink, one that can be extruded and carefully aligned to produce complex color gradients.

A 3D printable liquid crystal ink

The Eindhoven ink’s reflective qualities are dependent on the precise helical alignment of the material’s molecules, which can be closely controlled during the printing process by varying parameters such as print speed. The ink’s molecules are also capable of self-assembling into structures that mimic natural iridescent materials, meaning nature-inspired color changes are entirely possible. Additionally, the ink is easy to produce and viscous, which makes it easy to process via direct ink writing.

Sol adds, “To successfully print the new ink with DIW, we varied parameters like print speed and temperature. And to get the ink to print properly, we also made an ink containing low-molecular-weight liquid crystals. Traditionally, this level of control is only possible with very specialized fabrication devices, so to do this with the new ink and DIW 3D printing is a real breakthrough.”

Although the ink has only been used to print a color-changing butterfly so far, Sol believes it can be applied to personalized medical devices such as visually dynamic wearable biosensors. The ink may also have potential applications in the optical structures of augmented reality headsets.

Sol concludes, “The new materials could find their way into the HoloLenses of the future—now that would be something extraordinary!”

Further details of the study can be found in the paper titled ‘Anisotropic Iridescence and Polarization Patterns in a Direct Ink Written Chiral Photonic Polymer’. It is co-authored by Jeroen Sol et al.

Innovations in 3D printing materials are a major contributor to the advancement of functional additive manufacturing applications. Earlier this month, scientists from Nanyang Technological University (NTU) Singapore and the California Institute of Technology (Caltech) 3D printed a flexible chain mail-inspired fabric that can stiffen on demand. 3D printed from nylon plastic polymer octahedrons that interlock with each other, the fabric can turn into a rigid structure that is 25 times stiffer than its relaxed form.

Elsewhere, the Institute for Soldier Nanotechnologies (ISN) recently used 3D printing technology at the nanoscale to form a material that is reportedly more effective at stopping a projectile than Kevlar or steel. Thinner than a single human hair, the material is made from tiny carbon struts that form interconnected tetrakaidecahedrons – structures with 14 faces – that are fabricated via two-photon lithography.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a butterfly 3D printed using the new liquid crystal ink. Photo via Eindhoven University of Technology.