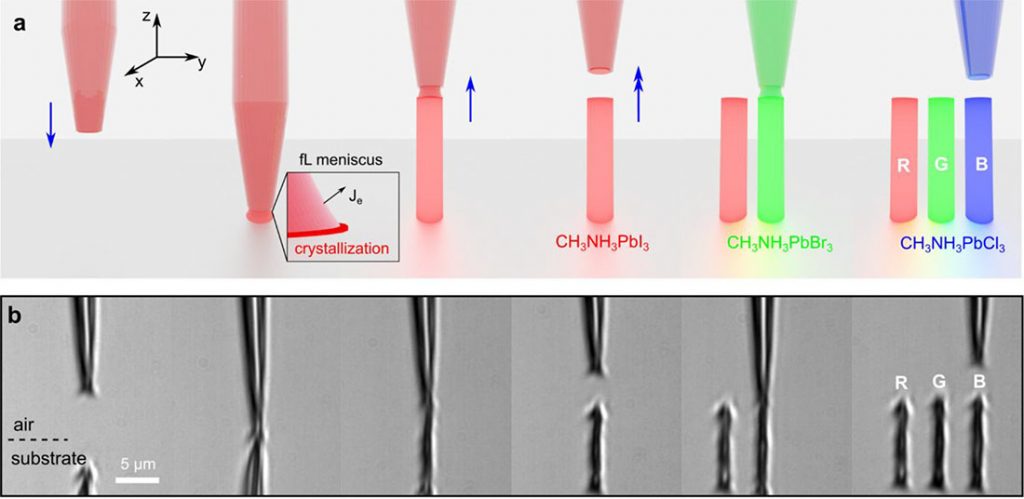

A team of researchers from Hong Kong University and the Korea Electrotechnology Research Institute (KERI) have used 3D printing to create nanoscale display pixels made of perovskite.

Just last year, the same group of scientists used liquid inks and direct ink writing to fabricate display pixels capable of emitting light. Now turning their attention to perovskites, a type of compound found in solar cells, the researchers believe they can achieve even greater brightness levels and higher resolution displays using a similar deposition-based 3D printing technique.

Dr. Jaeyeon Pyo, a Senior Researcher at KERI and co-author of the study, believes the 3D printing of light-emitting perovskites can also go on to unlock previously impossible applications in the field of security. For example, the study refers to a multilevel encryption system for the anticounterfeiting of currency notes, whereby nanoscale patterning on dollar bills would enable us to determine if a particular note is genuine or not.

3D printing and perovskites

Perovskites are a promising choice of material for several optoelectronic applications due to their exceptional structure and extensive tunability. The compounds offer a number of excellent properties such as large optical absorption, long carrier diffusion length, and high carrier mobility, and they emit light in the presence of a voltage. Unfortunately, their use-cases have been limited to 2D systems until now, owing to a lack of 3D production methods.

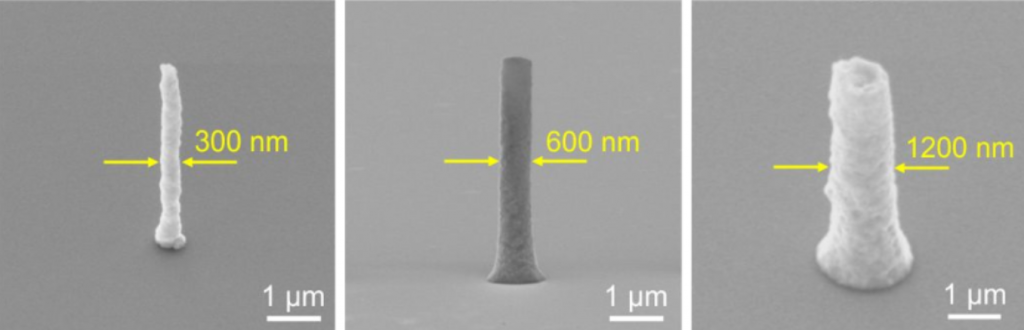

From prior research, Pyo’s team has already demonstrated that emission intensity (brightness) increases in line with the height of a 3D printed nanopixel. Building on this, the most recent study shows that this intensity can be saturated even further by the depth of field of the optical system used to measure the pixels. Interestingly, the saturation can be leveraged to enable more advanced applications using 3D printed perovskites.

Pyo explains, “Previously, precise control of the height was required for flattening the brightness of the individual 3D printed pixels. Instead, printing the pixels to the height over the saturation point can provide a uniform brightness without delicate individual height control.”

What this means is that information can be stored securely at different heights in a perovskite pixel. Since the difference in heights over the saturation point is visually indistinguishable using ordinary measurement instruments, the data stored at the different heights would only be accessible using a very specific 3D measuring method – one that only the developers of the pixels would have access to.

High-resolution displays and multilevel security

So how is this applicable outside the lab? One of the most immediate applications is high-resolution optical displays, whereby the 3D printed nanoscale perovskites can be used to filter color in a backlit display device.

Pyo and the rest of the researchers can also see potential applications in identification, authentication, and currency anticounterfeiting. The 3D printed nano pixels could provide multi level encryption with fluorescent patterns that are only visible with UV light, a microscope, and a specialized, one-of-a-kind 3D measurement system. As such, authorities like central banks could verify whether a specific bank note is authentic or not by checking for the nanoscale perovskite patterning.

As far as further work goes, the team is now transitioning from passive illumination to electrically-driven lighting with the 3D printed perovskite pixels. Pyo explains, “Going beyond the passive lighting from photoluminescence, electrically driven lighting shall open up the possibility of actively controllable lighting devices.”

Further details of the study can be found in the paper titled ‘Three-Dimensional Perovskite Nanopixels for Ultrahigh-Resolution Color Displays and Multilevel Anticounterfeiting’. It is co-authored by Jaeyeon Pyo, Ji Tae Kim et al.

The applications of nanoscale 3D printing go beyond just security and authentication. Earlier this year, researchers from the Technical University of Denmark (DTU) repurposed a component from a Microsoft Xbox 360 to develop a high-resolution nanoscale 3D printer with various applications in the medical sector. The team picked out the optical pick-up unit (OPU) from the console to replace a conventional SLA optical system, enabling printing resolutions down to hundreds of nanometers.

Elsewhere, scientists from the Swiss Federal Institute of Technology Lausanne (EPFL) have previously 3D printed a mechanical microdevice capable of biopsy (cell collection) and drug delivery when implanted in human skin. The implant, just a few microns in width, is powered by what is called an “acoustic microengine”, a 3D nanoprinted pump made of hydrogel.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows SEM imaging of the 3D printed perovskite pixels. Image via KERI.