A team of researchers from Nanyang Technological University, University of Chemistry and Technology Prague, and the King Saud University have 3D printed electrodes capable of detecting mycotoxins in food. Detailing their work in a recent issue of Electrochemistry Communications, the scientists believe their study could pave the way for a novel method of food safety assurance.

Mycotoxins

Mycotoxin zearalenone (ZEA) is a poisonous secondary metabolite. It is produced by the Fusarium species of fungi and can typically be found in maize products containing wheat such as cereal. Under certain conditions, ZEA can cause food products to turn moldy, making them extremely dangerous to consume. According to the study, contaminated products can lead to cancer or even death in humans. For this reason, timely and reliable methods of detecting ZEA are crucial for food inspectors to mitigate the spread and keep the products in food storage facilities safe until they reach the shelf.

3D printed graphene electrodes

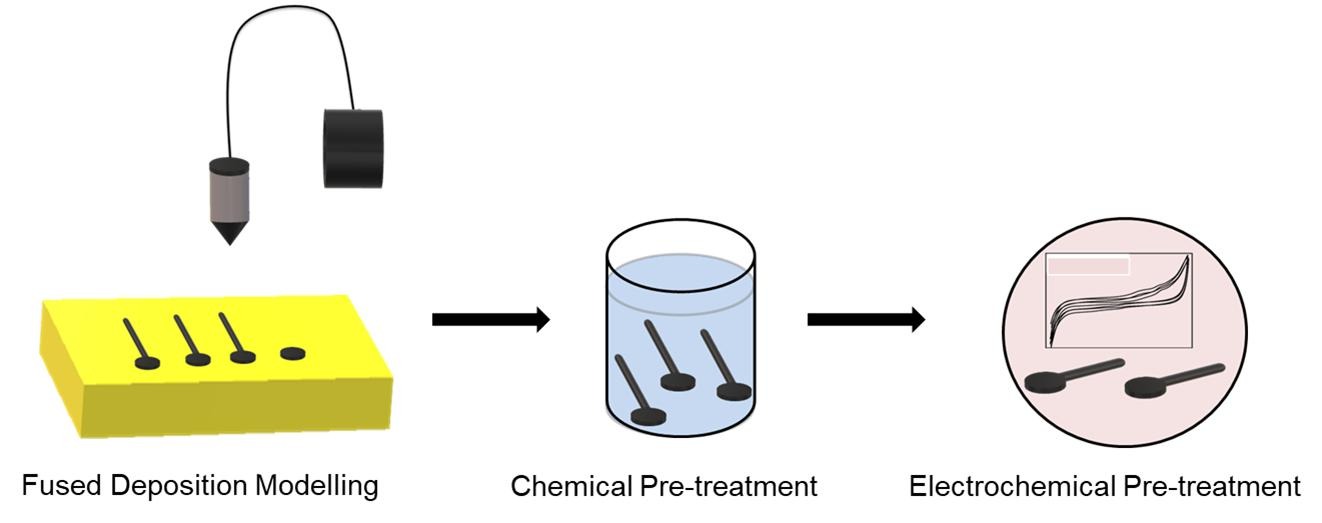

The team started off by designing the electrodes in Autodesk Fusion 360 CAD software. The design consisted of a 1.6mm thick disc attached to a rectangular stem with a length of about 4.5cm. Printing was done on a Prusa i3 MK3 FDM 3D printer, and the electrodes were made from graphene/PLA filament. Once printed, the electrodes had to be pre-treated to increase their sensitivity to ZEA. They were soaked in DMF for ten minutes and washed with ethanol and deionized water. As a result, the inert PLA external layer was removed and the inner graphene was exposed and activated.

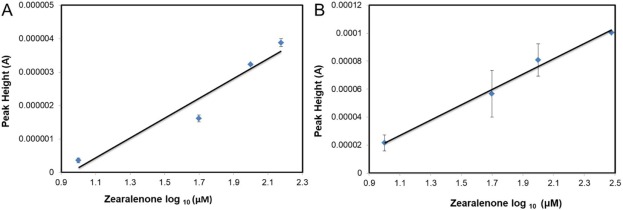

The 3D printed electrodes were compared to a standard set of Ag/AgCl electrodes and while they were not as electroactive, the graphene set still did a fairly good job of detecting ZEA. The researchers calculated a respectable linear response of r=0.995 over a wide range of ZEA concentrations (10 – 300µM). Ultimately, the team concluded that their work was suitable for a proof-of-concept, opening up a great number of possibilities for research studies focused on 3D printing electrochemical devices for food safety and analysis.

Further details of the study can be found in the paper titled ‘3D-printed electrodes for the detection of mycotoxins in food’. It is co-authored by Muhammad Zafir Mohamed Nasir, Filip Novotný, Osamah Alduhaish, and Martin Pumera.

The 3D printing of precise electrodes for sensor applications is becoming easier and easier with advancements in 3D printing technology. Earlier this year, a team of U.S. researchers 3D printed a working carbon monoxide detector with 3D inkjet printed silver electrodes. Upon testing the detector, the researchers found that it was able to function at room temperature with a fast response time. Elsewhere, in Korea, researchers 3D printed a set of highly sensitive, wearable biosensors. The biosensors have since been used to conduct a sleep study and a treadmill study measuring neuron activity under the skin.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows mycotoxin growing on corn. Image via World Grain.