Metal 3D printing specialist Sciaky has announced that it will be joining Siemens’ PLM Software Solution Partner Program.

As a partner in software and technology, Sciaky will integrate the company’s product lifecycle management systems into its manufacturing processes, creating a digital thread between concept design and the end customer.

Adoption of the software has been made to facilitate connection with Siemens customers around the globe, and strengthen Sciaky’s position within the metal additive market.

Adding value to metal 3D printing and PLM

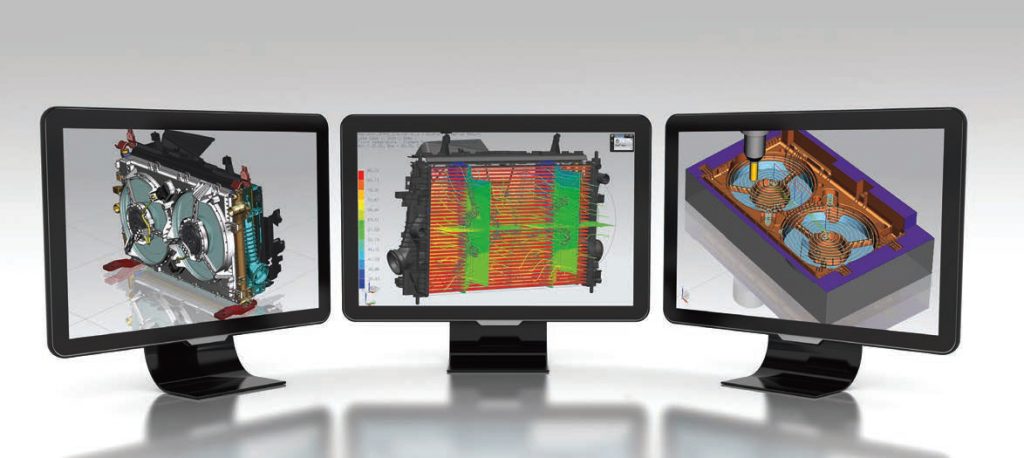

As in previous PLM solutions partnerships, the Siemens NX and NX Nastran softwares will be added to the Sciaky system.

NX will provide the company with a transferrable platform for computer-aided design, manufacturing and engineering (CAD/CAM/CAE). And NX Nastran is to deliver computer-aided engineering analysis.

According to Vynce Paradise, Director of Advanced Part Manufacturing at Siemens PLM Software, “Siemens PLM Software is committed to creating partnerships that can add value to the business of our customers.”

“We are pleased to work with Sciaky as they use the latest multi-axis deposition technology we have developed within NX software to support their EBAM 3D metal printing systems.”

Getting ahead of the competition

The partnership with Siemens comes at an interesting time for Sciaky as technologies targetting similiar applications to EBAM are spreading.

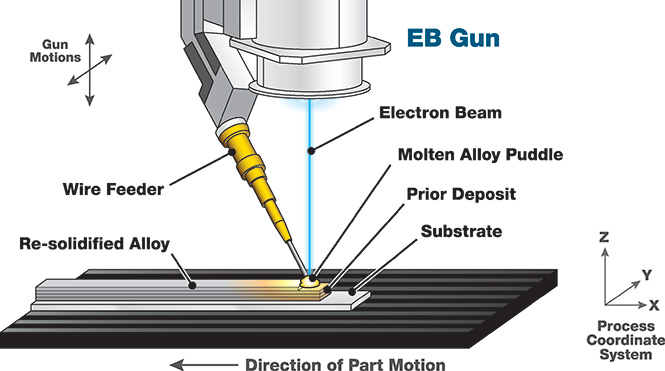

Electron beam additive manufacturing (EBAM) is Sciaky’s registered metal 3D printing approach.

In development since the early 2000s, the process is capable of laying between 3.18 and 9.07 kilograms of metal per hour making it “the fastest deposition process in the metal additive manufacturing market” to date.

As some companies approach the market via acquisition rather than collaboration, a partnership with the largest manufacturing company in Europe is also key to Sciaky’s stance on an international scale.

Other companies in a PLM agreement with Siemens include Materialise and fellow metal 3D printing company Trumpf.

Metal expertise

Most recently, Sciaky 3D printed a flight-integral part for the wing of commercial Airbus aircraft. The company also has existing partnerships with aerospace and defence provider Lockheed Martin, the U.S. Air Force and DARPA.

Siemens on the other hand has applied its software solutions to make the award winning 3D printed blades for gas turbines.

3D Printing Industry provides its subscribers with all the latest additive manufacturing partnerships and news on a daily basis. Sign up to our newsletter here, follow us on Twitter and like us on Facebook.

Register your interest in 3D printing jobs on our forthcoming site here.

Featured image: Laser scanning of an EBAM 3D printed metal part. Screenshot via Sciaky Inc. on YouTube