Chicago-based additive manufacturing company, Sciaky have been contracted to produce a metal 3D printed component for International Submarine Engineering’s (ISE) AUV submarine. The production of this component has elevated Sciaky’s status to become the only metal 3D printing company to have parts approved for application in land, sea, air and space.

The ISE are an internationally recognized engineering company who design and integrate remotely operated and autonomous vehicles. While Sciaky are a leading metal 3D printing company with their patented Electron Beam Additive Manufacturing (EBAM) technology. We took a closer look at Sciaky recently as they reach for the skies under an agreement with Airbus.

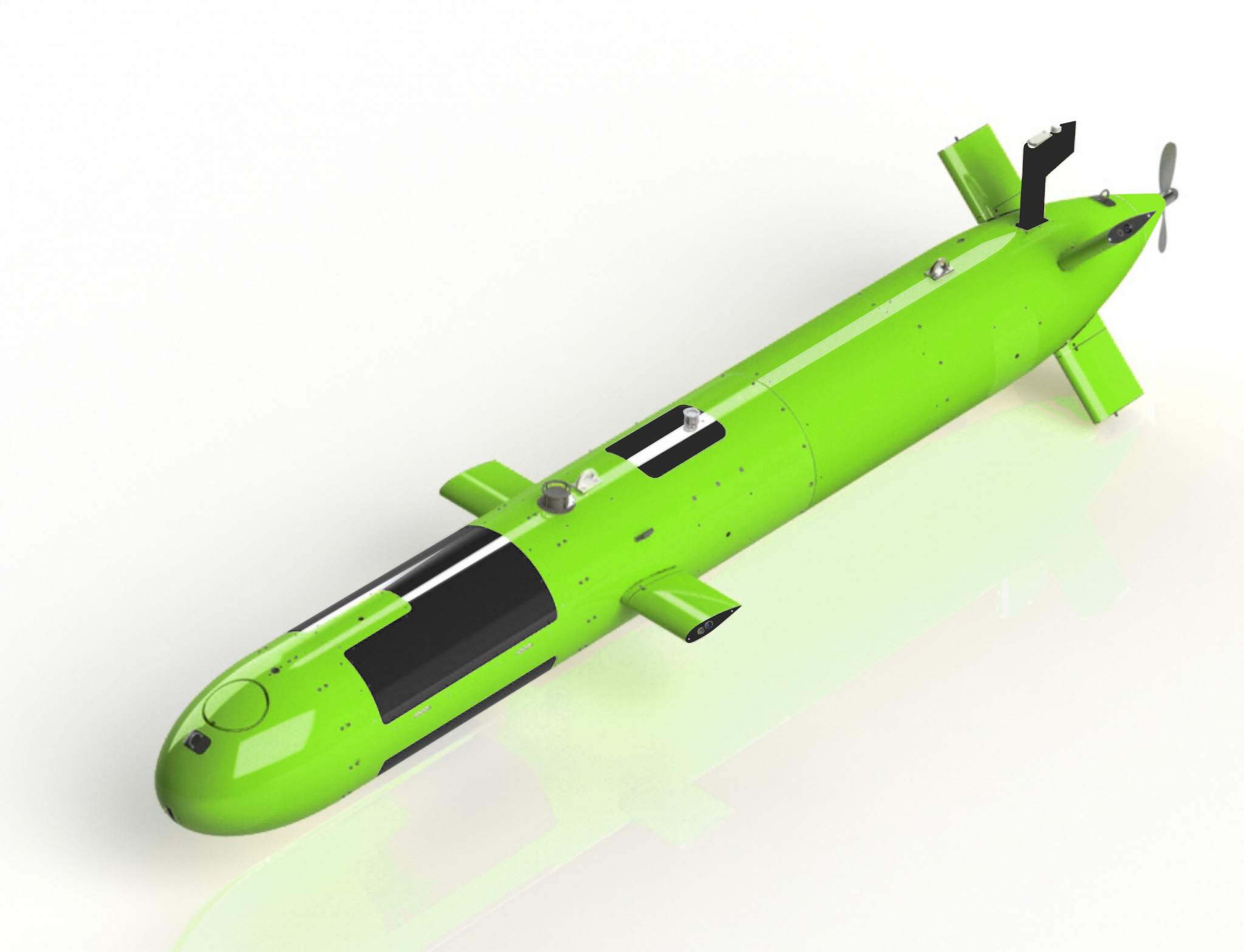

The 3D printed component has been incorporated into the Arctic Explorer AUV vehicle, which is scheduled to be delivered to the University of Tasmania in the Spring of 2017. Once undergoing testing, the unmanned submarine will be deployed in the Antarctica. Similarly, we also reported on a smaller-scale 3D printed submarine, in the form of the ArcheoROV.

The 3D printed component

Sciaky has manufactured a 3D printed titanium ballast tank. The ballast tank is an integral part of any water-based vehicle as it provides stability for the vessel. The tank will hold water and will help the submarine dive and emerge. The ISE previously outsourced production of this part to an overseas titanium forging company who were unable to deliver, but then opted for Sciaky with time and efficiency in mind. The engineering company were reportedly impressed by Sciaky’s involvement with space company Lockheed Martin. Following the success of this production, “ISE now plans to 3D print other critical titanium parts with Sciaky’s EBAM process.”

Using this advanced manufacturing technique,

The VB tank created with Sciaky’s EBAM process passed the same vigorous qualification testing as the tank previously created with the forging process.

Benefits of 3D printing the component

Using Sciaky’s EBAM process reduced both costs and production time. According to Sciaky, they halved the time required to manufacture from 16 weeks to just 8.

The Arctic Explorer AUV with the 3D printed component will be used as a research vehicle. With ISE producing two of these AUVs before for Defense Research and Development Canada to “map the sea floor underneath the Arctic ice shelf.” The underwater vessel is over seven meters long and weighs over 2,000 kg. The unique variable ballast tank system enables the vehicle to park itself on the sea floor and reach depths of up to 5,000 meters below the surface.

Bob Phillips, Vice President of Marketing for Sciaky, had this to say,

Sciaky is proud to help ISE cut production time by 50 percent and reduce costs by 3D printing their titanium VB tank with our one-of-a-kind EBAM process. Our industry-leading EBAM technology is the world’s only industrial-scale metal 3D printing solution with approved parts for land, sea, air, and space applications.

Sign up to our newsletter to stay up to date with 3D printing news.

Featured image shows one of ISE’s AUV submarines. Image via International Submarine Engineering.