Sakuu Corporation (formerly KeraCel), a specialist in 3D printed energy storage devices, has been awarded three new patents.

Each of the patents are intended to improve the efficiency and flexibility of the company’s multi-material additive manufacturing capabilities, which are used to 3D print solid-state batteries.

The first of the patents is a new hybrid solid-state cell design with a sealed anode structure. The other two are additive manufacturing systems, one of which can fabricate stacked active devices such as micro-reactors and batteries, while the other is an electrographic 3D printer.

Multi-material 3D printing with Sakuu

Backed by Japanese automotive manufacturer Musashi Seimitsu, Sakuu is focused on 3D printing high-performance solid-state batteries for applications such as e-mobility. Since rebranding from KeraCel earlier this year, the company has launched its own industrial-grade 3D printer designed specifically for fabricating electric vehicle (EV) batteries at scale.

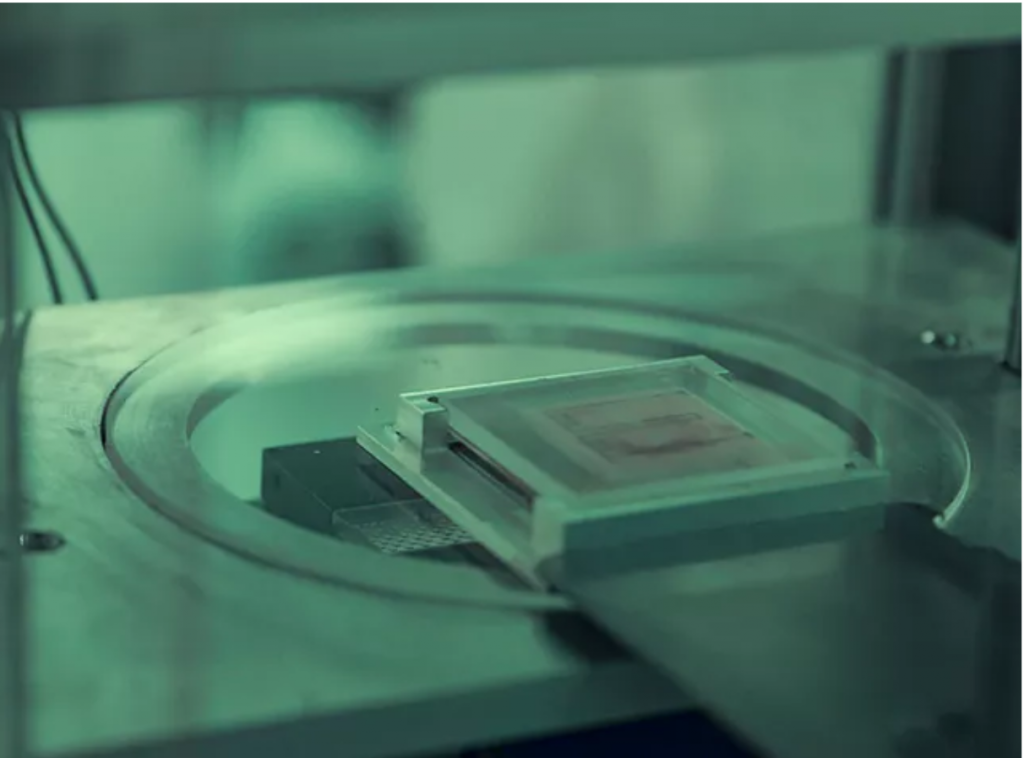

Dubbed the ‘Sakuu AM Platform’, the system features multi-material 3D printing capabilities. By combining powder bed technologies with material jetting, the machine is able to work with ceramics, metals, and the company’s own ‘Poralyte’ support material within individual layers. According to the firm, the Sakuu AM Platform is able to produce solid-state batteries with twice the capacity of traditional cells, all while slashing material consumption in half.

“Solid-state batteries are a holy grail technology, but they are both very difficult and expensive to make,” explains Robert Bagheri, Founder and CEO of Sakuu. “By harnessing the flexibility and efficiency-enhancing capabilities of our unique and scalable AM process, we’re enabling battery manufacturers and EV companies to overcome these fundamental pain points.”

Three new patents

Sakuu’s first new patent is for a monolithic electrochemical cell housing made of ceramic. The structure is complete with space for an anode and a cathode, along with a separator cutting between the two. This novel housing reportedly enables higher charging rates, but without the safety concerns associated with conventional lithium-ion batteries. The design complements two other patents granted to Sakuu back in 2020 – one for an integrated cell stack battery and one for a monolithic solid-state battery.

Sakuu writes, “Collectively these structures enable increased energy density for solid-state batteries, without compromising stability and lifespan.”

The company’s second new patent is for a 3D printing system that enables users to assemble patterned layers into functional 3D devices on an assembly plate. It includes a carrier substrate that dispenses layers of material (which are 3D printed separately) into a stack, creating active devices like solid-state batteries with reduced material use and weight.

Finally, the third new patent is a 3D printer based on electrography, aka xerography. The imaging process is commonly used in copiers, faxes, and digital 2D printers to produce prints from digital files. The technology is characterized by its speed, being able to print large areas with thin layers and very high precision.

Scaling it up to the third dimension, Sakuu’s novel system is capable of 3D printing active devices such as batteries using a composite toner material, as well as a selection of ceramics, metals, and polymers.

3D printing energy storage devices

Through complex geometries, 3D printing can improve the performance of energy storage devices. Earlier this year, researchers from the California Institute of Technology (Caltech) developed a novel method of 3D printing electrodes for lithium-ion batteries. Using DLP 3D printing technology, the team was able to fabricate complex structures made of electrode materials, with reports of excellent battery capacity and stability.

Elsewhere, in industry, 3D printer manufacturer Photocentric launched an entire division dedicated to the development of eco-friendly 3D printed electric batteries. Having previously led several other grant-funded projects, the company has now dedicated further resources to optimizing 3D printed fuel cells for automotive applications.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the inside of the Sakuu AM Platform. Photo via Sakuu.