Two-photon lithography is a method of 3D printing that can produce objects on a molecular scale. Valuable to the fields of medical research, i.e. devices for drug delivery, tissue regeneration, chemical & material synthesis, the technology warrants deeper development to help expand the possibilities of the technology and lower the cost.

In a study led by a team at the Russian Academy of Sciences (RAS) in Moscow, researchers have explored an “unprecedentedly effective” method of high resolution 3D printing that eradicates some of the shortcomings associated with existing technology.

Laser control

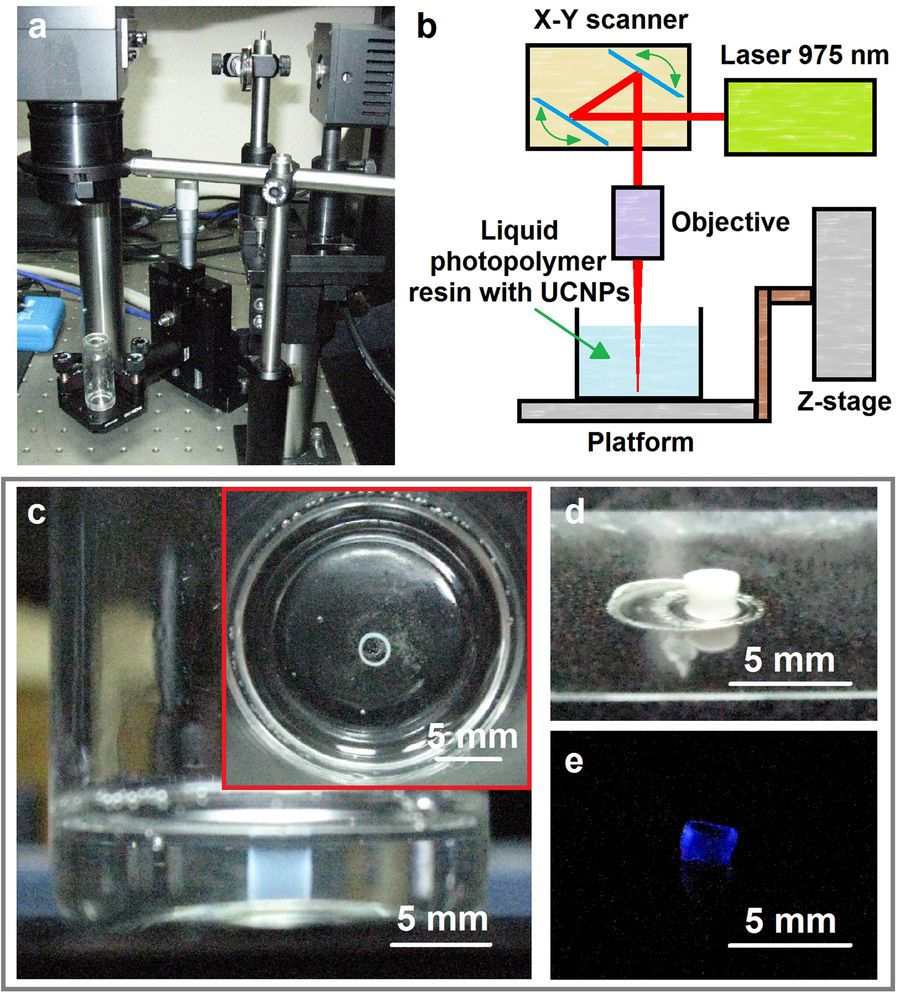

The RAS high-resolution 3D printing method is based on vat polymerization technology, where a light source is to solidify a resin.

In two-photon lithrography, femtosecond lasers are used to precisely cure the resin. Not only is the spot-to-spot process time consuming, but the lasers work at high intensities, which can damage materials, and the instruments are expensive.

Lasers in two-photonlithrography operate at the near-infrared (NIR) phase of light. The RAS technique also uses NIR light but at a lower intensity. To make the most of the light’ potential energy and eradicate some of the shortcomings of the femtosecond lasers as listed above the scientists add something new to the mix.

Making macro and micrometer scale objects with less

Upconverting nanoparticles (UCNPs) are made of two or more photons that join together and emit more energy when exposed to a light source. In the RAS study, UCNPs are added to the photo curable resin mix.

Under a ray of NIR light, the UCNPs form to emit a UV light. This light, in turn, polymerizes surrounding material to make a voxel.

The success of the process is that it high-resolution objects are made using a relatively low-intensity NIR light source. Photoplymerization also occurs deeper within the resin vat, giving the technique the potential to 3D print within biological tissues.

In-situ 3D bioprinting

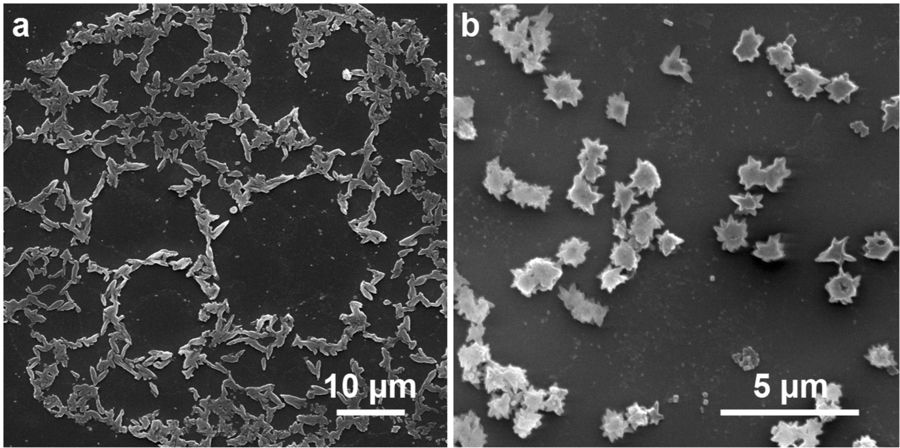

The overall conclusion of the study is an “unprecedentedly high conversion efficiency in the UV range,” successfully demonstrating NIR-induced polymerization for macro and micrometer scale objects.

According to Kirill Khaydukov, co-author of the RAS study, “This idea can be used for biomedical purposes, including tissue engineering, and replacing damaged parts of organs and tissue with the help of various polymer materials,”

In addition;

“We expect that our technology will allow us to create designs with the right sizes and properties inside living tissue to repair damage.”

Full results and discussion of the study “High-resolution 3D photopolymerization assisted by upconversion nanoparticles for rapid prototyping applications” are available online in nature’s Scientific Reports. The paper is co-authored by Vasilina V. Rocheva, Anastasia V. Koroleva, Alexander G. Savelyev, Kirill V. Khaydukov, Alla N. Generalova, Andrey V. Nechaev, Anna E. Guller, Vladimir A. Semchishen,

Boris N. Chichkov and Evgeny V. Khaydukov.

For more leading research news subscribe to the 3D Printing Industry newsletter, follow us on Twitter, and like us on Facebook.

Looking to get involved in a new project? Join 3D printing jobs for the latest vacancies in software, hardware and materials.

Vote now in the 2018 3D Printing Industry Awards for research/academic of the year and more.

Featured image shows a cluster of voxels produced by the RAS high-resolution photopolymerzation technique. Image via Scientific Reports