British 3D printer manufacturer RPS has launched a new polymer research and development tool called the NEO Material Development Kit. It is designed to work with the company’s NEO800 SLA 3D printer, and will allow R&D firms to develop a range of innovative polymers reportedly unavailable in the industry today.

Designed by RPS engineers, the kit comes in a range of vat and platform sizes. RPS has also created a module for the NEO Material Development Kit in its proprietary Titanium software, allowing users to develop materials and processing parameters. The new tool enables developers to use multiple resin formulations simultaneously, therefore offering immediate scalability at different stages of the material development process.

David Storey, Director of RPS stated “This NEO Materials Development Kit now opens the door for large industrial chemical companies such as BASF, DSM and Heinkel to push the boundaries of UV photopolymers.”

“The industry is looking for a quantum jump in materials to print end-user production parts from the stereolithography process.”

Material R&D at RPS

RPS is an industrial 3D printing specialist with over 10 years of experience in stereolithography technologies. The NEO800, introduced by the company in 2016, was developed with an open materials platform to encourage material R&D, which has now been supplemented with the NEO Material Development Kit.

3D Printing Industry spoke to David Storey, Operations Director at RPS, in November 2018, where he explained that “[The NEO800] is not locked to a specific manufacturer. This allows material development specialists to further research and development. Up until now, this has been a rather closed community.” According to Storey, materials are the key component driving additive manufacturing in markets such as automotive and aerospace.

Since October 2010, RPS has also been in a materials development partnership with Advanced Laser Materials (ALM), a subsidiary of leading 3D printer provider EOS. Together, RPS and ALM have designed and produced a broad range of specialty laser sintering (LS) materials for high-value industries including high-impact sports, consumer products and automotive industries, particularly Formula One.

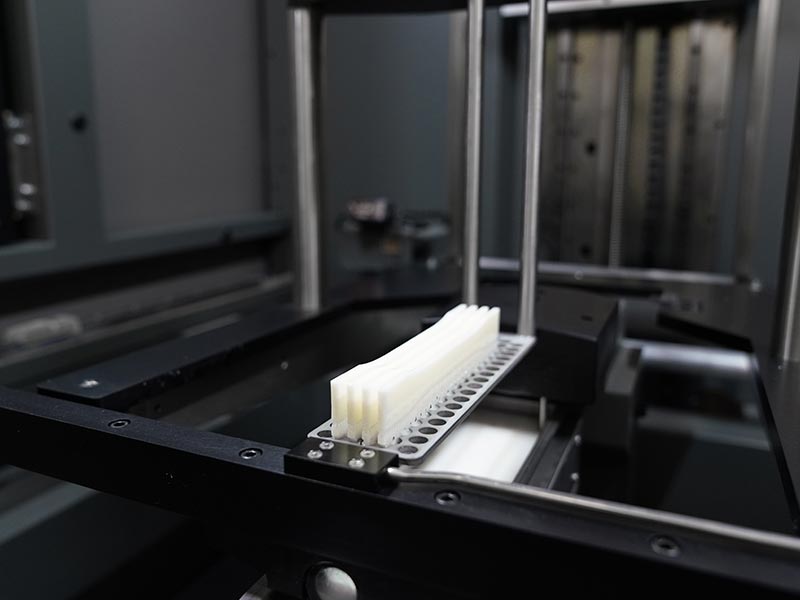

The NEO Material Development Kit

Using the NEO Material Development Kit, developers can iterate their material formulations through tensile testing. Beginning with the smaller 1 litre vat, containing a build envelope of 45 x 165 x 40mm (XYZ), and the Titanium software, users can 3D print single layer exposure panes. This can help to determine the photo-speed of the formulation being developed. The formulation, photospeed and settings of the photopolymer can then be tested, adjusted and retested in order to achieve the desired mechanical properties, once the critical exposure has been established.

Using the larger vat sizes, developers are then able to scale up once the testing is complete. The larger vat can take 13 litres of photopolymer and has a build envelope of 230x165x150mm (XYZ), suited towards 3D printing prototype parts for optimizing the final configuration settings.

RPS is exhibiting at the TCT show this week in Birmingham, UK, taking place from 24-26 September. The company will be available at stand D40, where the public can learn more about the NEO Material Development Kit. RPS will also be showcasing the NEO800 SLA system.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the NEO Material Development Kit. Photo via RPS.