Russian state-owned industrial technology conglomerate Rostec has received a license from the Russian Ministry of Industry and Trade to serially produce aerospace parts using additive manufacturing.

With the license, which reportedly allows the production and testing of components for civil airlines, helicopters, and engines, Rostec has become the first Russian company to confirm its competence in deploying mass industrial 3D printing for the aviation sector.

Aerospace 3D printing at Rostec

Rostec’s Additive Technologies Center reportedly holds the largest fleet of 3D printing equipment in Russia, and has so far mastered the production of around 450 types of aerospace parts.

The center was introduced in 2018 after the firm allocated $44.5 million to its development. The center was named after a celebrated inventor and nitrogen chemistry specialist, the VV Chernyshev Center for Additive Technologies (CAC), and was established in cooperation with three other members of Russia’s aviation cluster: Russian Helicopters, engineering firm Technodinamics, and radio electronic holdings KRET.

At the time, Rostec’s Industrial Director of the cluster, Anatoly Serdyukov, said “industrial 3D printing is becoming one of the indispensable attributes of modern industry.” Russian Helicopters echoed this view, having committed to advancing additive manufacturing within its Ka series helicopter line.

The following year, Rostec’s subsidiary Ruselectronics announced it was developing an electron beam metal 3D printer specifically geared towards aerospace applications.

Licensing serial production

Rostec’s additive technologies center has now been awarded a license from the Russian Ministry of Industry and Trade for the mass production of 3D printed aircraft parts. The license enables Rostec to serially produce and test aerospace components for use in civil aviation applications such as aircraft, helicopters, and engines.

According to Rostec, industrial 3D printing can shorten production times of certain aerospace components from six months to just three weeks. The company has also observed weight benefits, with 3D printed parts proving substantially lighter than those that are manufactured by conventional means.

In turn, this allows for increased payloads and carrying capabilities for its aircraft while also improving various other aircraft characteristics. Rostec has already started mass 3D printing parts for the Russian aircraft engine PD-14 developed by the United Engine Corporation. By 2024, the firm’s additive technologies center is expected to produce about 2,000 elements of the engine’s fuel system.

“Aircraft building is one of the most knowledge-intensive industries with increased safety requirements,” said Vladislav Kochkurov, Director General of JSC ATC. “The license confirms compliance with these requirements and allows the production of products in series.

“This is a new important stage in the development of additive technologies and the Russian aircraft industry.”

Serial production for aerospace

While the aerospace sector has leveraged the efficiency, design and lightweighting benefits of 3D printing technologies for many years, the stringent safety, regulation and performance requirements of critical parts has meant that, in many cases, the technology has been slow to scale up to mass production levels for end-use parts.

Saying that, in August last year 3D printer manufacturer EOS, industrial 3D printing service provider Baltic3D and MRO services provider Etihad Engineering announced they were exploring the serial 3D printing of interior aircraft parts. The R&D project will see Baltic3D print thousands of material samples using EOS’ laser sintering technology from which, once certified to be in accordance with aviation standards, prototypes will be printed for aircraft interior part designs.

In-flight entertainment systems developer Cabin Management Solutions is also producing series of 3D printed components for luxury aircraft, leveraging Markforged’s 3D printing technology to create FAA-compliant parts.

Elsewhere, air distribution systems manufacturer Senior Aerospace BWT has installed two Stratasys Fortus 450mc 3D printers to 3D print interior aircraft parts for its customers in-house, while aerospace firm Airbus qualified 3D printing service provider Materialise to produce flight-ready components for its aircraft.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

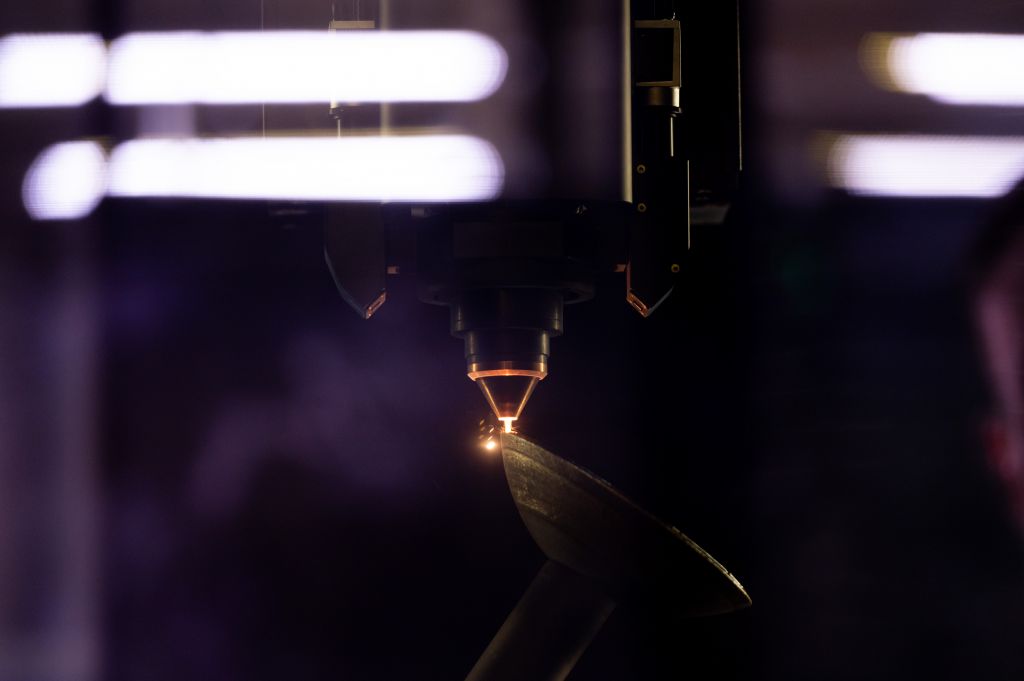

Featured image shows Rostec is now licensed for 3D printing-based mass production for the aircraft industry. Photo via Alexander Utkin.