Educational additive manufacturing programs are becoming more common within colleges and universities

From the GE Additive Education Program (AEP), which saw GE investing $10 million over five years towards polymer and metal 3D printers for colleges and universities around the world, to the MakerBot Certification Program, which trains classroom educators into 3D printing experts, it is evident that new technologies continue to be integrated into educational curriculums.

With this rise of new technologies, European leaders have emphasized the importance of additive manufacturing in higher education in preparing graduate students with the skills for the changing industries.

This perspective derives from a recent study presented by the Ricoh Europe, a branch of global technology provider, Ricoh Group.

Adjusting to the reshaping industries

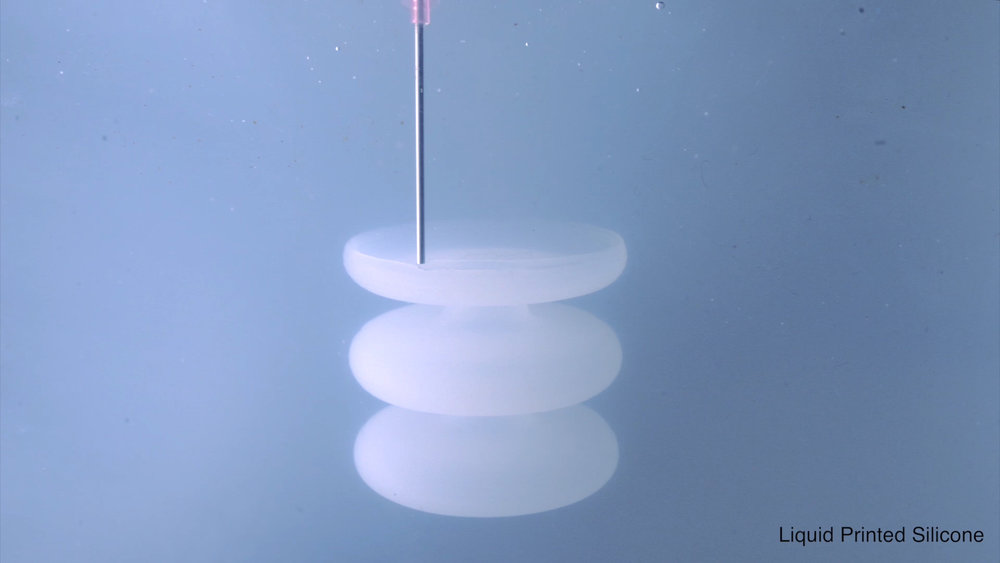

3D printing technologies have enabled efficient end-to-end production processes for those wanting to bring their ideas to life.

In healthcare, medical companies such as DePuy Synthes, have adopted 3D printing technologies to create patient-specific implants that promote the regrowth of bone tissue. In the automotive sector, car manufacturers such as BMW have implemented Rapid Liquid 3D printing techniques to develop customizable car interiors. Additionally, in aerospace, specialists such as

Norsk Titanium AS, have used metal 3D printing to create titanium parts for commercial aircraft.

“Digital fabrication and 3D printing provide the ability to illustrate complex concepts across a variety of subjects,” said David Mills, CEO of Ricoh Europe.

“As the way people and machines work together continues to evolve, integrating technical abilities into the learning process helps ensure the skills required of the future workforce become second nature for today’s students.”

Stressing the importance of new technologies, this study, which surveyed 3,100 business and educational professions across Europe, suggests that manufacturers that have not yet adopted 3D printing technologies will fall behind their competitors.

A new and improved curriculum

According to the study, 65% of those surveyed believe 3D printing is an increasingly important component of STEM-based learning. Therefore, students are becoming more interested in subject areas that use new technologies.

In an effort to appeal to the upcoming generation of young professionals, 66% of respondents suggest that educational institutions should invest in new 3D printing technology facilities, equipment, and courses.

A reported 48% of educational institutions are currently making course content and resources that incorporate 3D printing processes and materials.

“Encouraged to act more like ‘service providers’, universities and colleges must continually raise the bar in both student satisfaction and accessibility,” added Mills.

“Responding to this by using print in new ways to offer increasingly diverse courses and tailored syllabus content is fast becoming essential.”

Want to be informed with the latest in 3D printing news? Subscribe to the 3D Printing Industry newsletter. Also, follow us on Twitter, and like us on Facebook.

Looking for a change of pace or seeking new talent? Search and post 3D Printing Jobs for opportunities and new talent across engineering, marketing, sales and more.

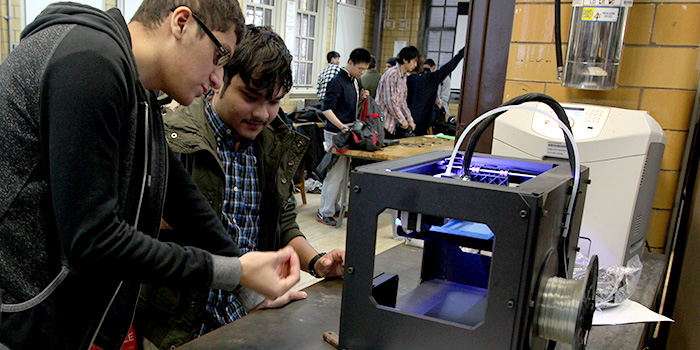

Featured image shows university students learning the 3D printing process. Photo via Open Source Classroom.