Researchers from the University of Delaware (UD) have released a new research paper exploring ways of economically upcycling biomass into new 3D printing materials.

Funded by the National Science Foundation Growing Convergence Research (NSF GCR) program, the paper focuses on lignin, a waste product left over from making paper products, and demonstrates that it is possible to efficiently turn it into bio-based 3D printing resins in an approach they claim is competitive with similar petroleum-based products.

“The ability to take something like technical lignin and not only break it down and turn it into a useful product, but to do it at a cost and an environmental impact that is lower than petroleum materials is something that no one has really been able to show before,” said Thomas Epps, NSF GCR lead at UD.

Repurposing lignin for 3D printing

Lignin is a chemical that provides strength and stiffness to plant cells walls, and is produced endlessly by plants to protect themselves from predators. As such, lignin is a widely available resource, with about 100 million tons of technical lignin waste generated annually in pulp and part mills around the world, UD says. While the researchers claim their research to be unique, there has been progress in this area by several other universities and 3D printing firms, too.

In 2020, Researchers from the University of Freiburg combined lignin with cellulose calls to develop their own environmentally-friendly wood-based 3D printing material. The biosynthetic polymer has potential uses within light construction or industrial applications.

Elsewhere, MIT scientists developed their own lab-grown wood cells containing lignin-reinforced walls that could form the basis of a new, more sustainable 3D printable biomaterial. Although still in its early stages, in future the research could lend itself as a means of 3D printing eco-friendly furniture or producing synthetic woods to address the growing global deforestation crisis.

Perhaps the most notable development in this area so far is Desktop Metal’s new Forust wood 3D printing technology launched midway through last year. The process upscales waste byproducts from wood, such as lignin and sawdust, to create sustainable 3D printing materials compatible with its binder jet technology.

Economically upgrading lignin

What sets the UD research apart from others in the area is its focus on the economics of the upscaling process. One of the main drawbacks of upgrading lignin is that many existing processes operate at very high temperatures, and are therefore expensive and difficult to scale. Current industrial techniques also still come with the safety concerns, capital costs, and energy consumption associated with traditional solvents, temperatures, or pressures.

To address these challenges, the UD research team replaced methanol, a traditional solvent used in lignin deconstruction, with glycerin to enable the process to take place at a normal atmospheric pressure. Glycerin is an inexpensive ingredient typically used in liquid cosmetics, soaps and shampoos for its moisturizing benefits, but can also be used to break down lignin into its chemical building blocks, from which a broad range of bio-based products like 3D printing resins can be made.

Replacing methanol with glycerin provided the same chemical functionality but at a much lower vapor pressure, eliminating the need for a closed system. This enabled the researchers to complete the process’ reaction and separation steps simultaneously, leading to a more cost-effective system.

According to the researchers, operating at atmospheric pressure is not only safer, but also provides a straightforward route to scale the method up from small batches to run continuously, which they say will create more material cheaper, faster, and with less manual labor.

Assessing economic viability

The method was developed over the course of a year to ensure its repeatability and consistency, and during this time the economic feasibility of the process was also assessed.

The team researched data sets on which types of products the team could create with their newly-created SLS 3D printing materials and estimate their physical properties. This allowed the team to model the system to see if the materials created would be economically viable.

The models assessed technical lignin waste from various pulping processes obtained from project partner CanmetENERGY in Canada. This enabled them to consider how upstream costs like the feedstock price or yield would impact the economics of the method further along the process.

According to the models, the UD’s low-pressure method could reduce the cost of producing a bio-based pressure-sensitive adhesive from softwood Kraft lignin by up to 60 percent compared to a conventional higher-pressure process. While the scientists acknowledge the cost advantage was less pronounced for other types of technical lignins used in the study, softwood Kraft lignin is one of the most commonly generated types of technical lignin by the pulp and paper industry.

The researchers’ analysis demonstrated that while yield plays a major role in plant economics, the cost to operate the new, low-pressure process was significantly lower than that of the conventional process “in all cases”, offering reduced capital costs and the generation of valuable co-products. The team also carried out a life-cycle assessment (LCA) to find out how much greenhouse gas emissions are generated by the process, the data of which can be used in the future to explore further ways to optimize the process.

With a patent currently pending for their ambient pressure process, the researchers believe the method offers “a lot of potential” for using renewable resources to make various types of plastics in favor of fossil fuels.

Further information on the study can be found in the paper titled: “Ambient-pressure lignin valorization to high-performance polymers by intensified reductive catalytic deconstruction,” published in the Sciences Advances journal. The paper was co-authored by R. O’Dea, P. Pranda, Y. Luo, A. Amitrano, E. Ebikade, E. Gottlieb, O. Ajao, M. Benali, D. Vlachos, M. Ierapetritou, T. Epps.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

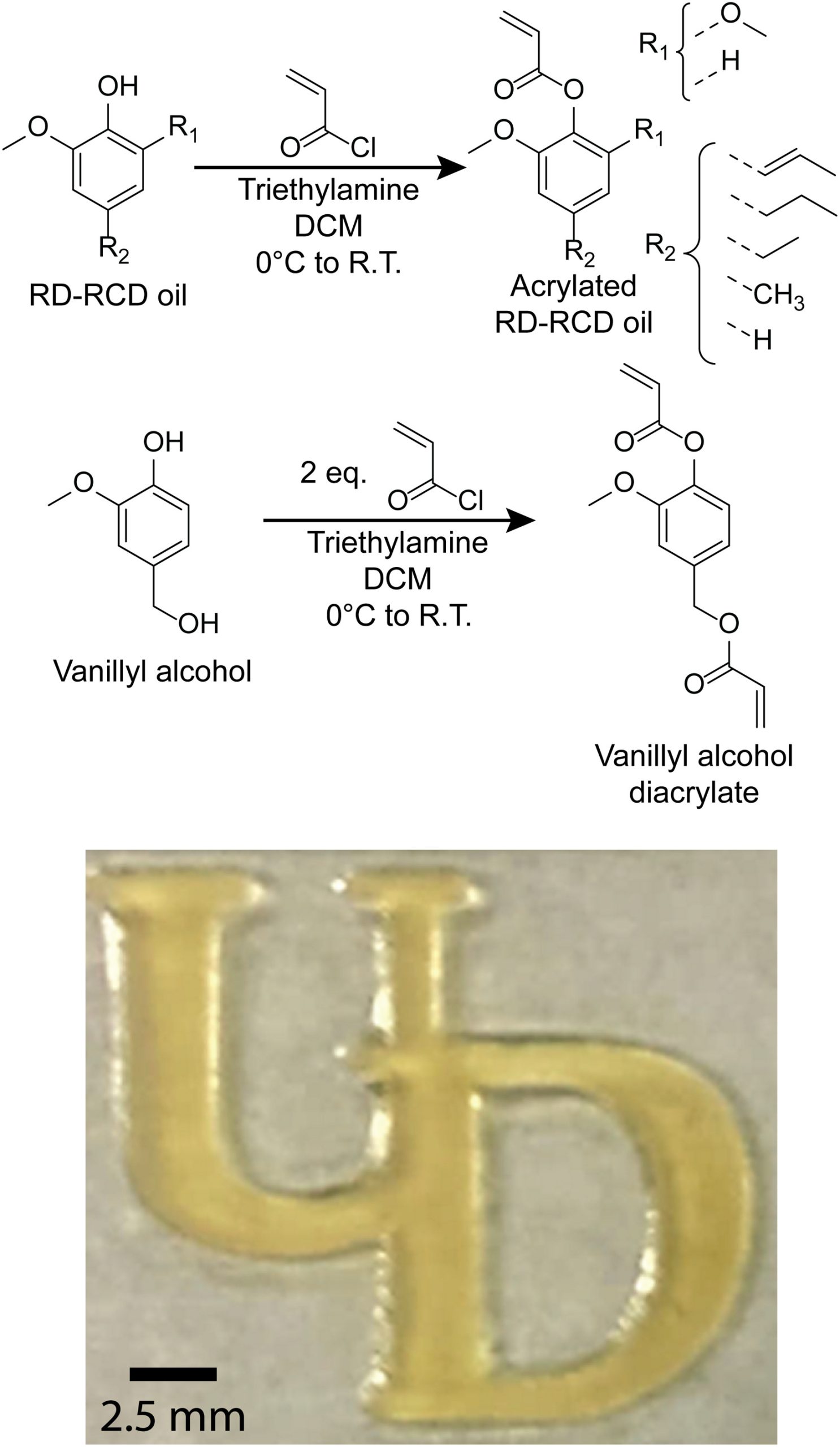

Featured image shows one of the end-products the UD researchers and colleagues are investigating is the creation of bio-resins for 3D printing. Photo via Paula Pranda.