Researchers from the University of Birmingham and University of Southern Queensland are exploring the use of micro-3D printing technology to create microneedles.

The approach leverages a process called two-photon polymerization (2PP), a form of highly-precise resin 3D printing that’s particularly adept at fabricating complex microstructures with resolutions in the nanometer range. 2PP has picked up steam in the academic sphere in recent years, with applications in microfluidic devices, photonics, micro-optics, and medical devices such as microneedle arrays.

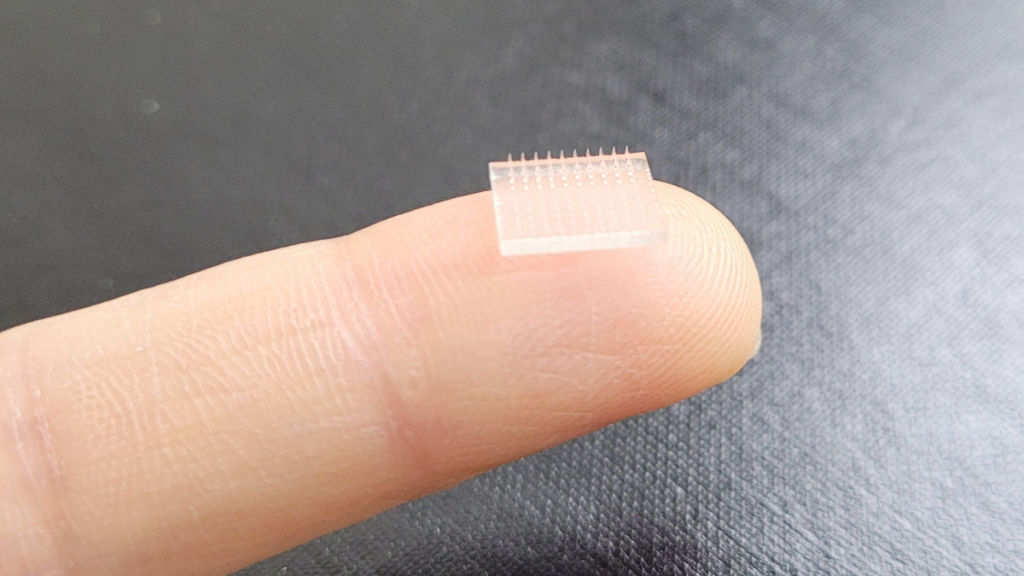

The multinational research team has now performed a parametric optimization of the 2PP process, specifically to develop polymeric microneedles with complex features such as side channels.

Down to the nanoscale with microneedles

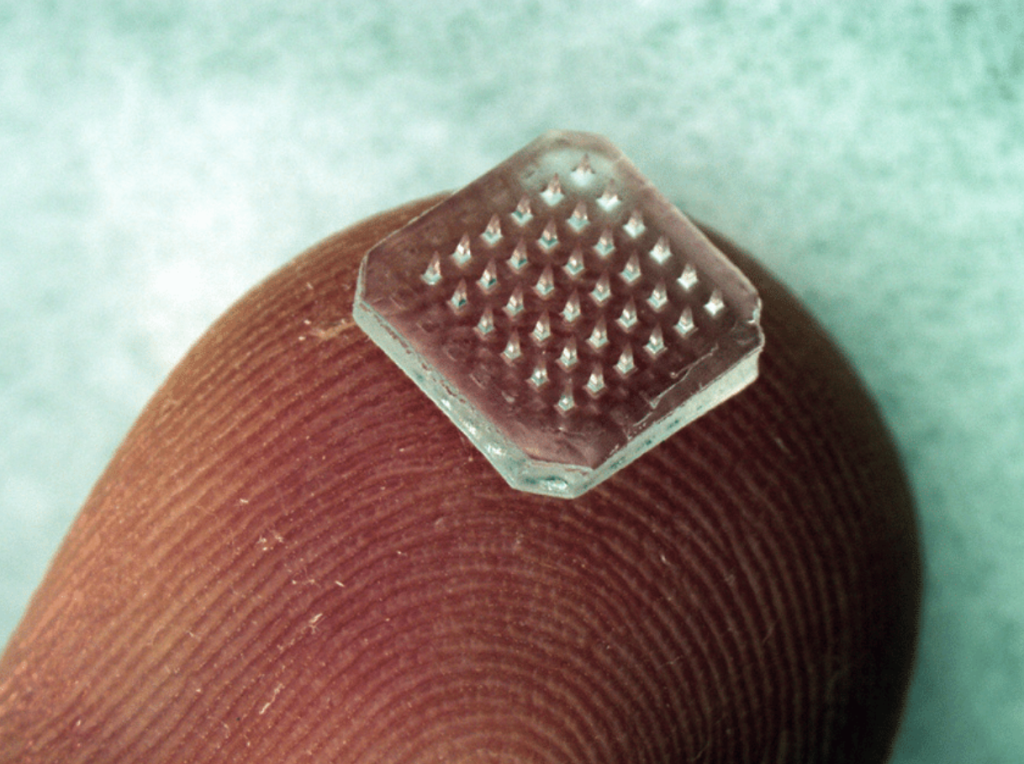

While conventional hypodermic needles are commonly used to extract blood samples and deliver compounds intravenously, microneedles and their miniaturized form factors have their own set of novel applications. This includes transdermal drug delivery across the skin barrier, withdrawal of tiny biosamples for diagnostics, and even cosmetic procedures.

Microneedles can be made of all manner of materials such as metals, silicon, glass, and even ceramics. Polymeric microneedles, in particular, are heralded for their biocompatibility and mechanical stability.

Polymeric variants can indeed be 3D printed via 2PP but selecting the optimal printing parameters to create a usable microneedle array often involves extensive testing. According to the research team, there’s also limited research when it comes to printing parameter optimization, making it an arduous procedure.

This isn’t to say it isn’t worth doing however, as scientists at Stanford University and the University of North Carolina at Chapel Hill (UNC) recently 3D printed a vaccine patch which they claim provides greater protection than a typical vaccine shot. Applied directly to the skin, the microneedle patch reportedly delivered an immune response ten times greater than a vaccine delivered into an arm muscle, all while being painless.

Elsewhere, at the University of Kent and the University of Strathclyde, researchers have previously developed a novel 3D printed microneedle device that uses microelectromechanical systems (MEMS) to closely control transdermal drug delivery. Named 3DMNMEMS, the device was developed with the goal of personalizing clinical treatment and allowing medical professionals to dose their patients based on their needs.

An optimized microprinting process

To conduct the project, the team made use of a Nanoscribe Photonic Professional GT 3D printer. The study involved printing a number of microneedle test samples with varying process parameters to identify an optimal combination. Eventually they settled on a laser power of 80mW, a print speed of 50,000µm/s, and slicing distances of between 0.5µm and 0.7µm.

Both the scan speed and the power of the laser were found to have significant impacts on the outcome of the builds, with faster scanning speeds resulting in lower levels (worse) of polymerization.

Looking now at the geometry of the microneedles themselves, the team found that an array with a long tip height of 300µm had the poorest performance in response to applied load. On the other hand, a microneedle array just 150µm long could withstand loads up to 50% higher before breaking. The printed parts also featured a side channel design that formed a microfluidic channel crossing the epidermis. Reaching the subcutaneous region, these channels could be used to deliver drugs and monitor biomarkers.

In skin penetration tests performed on pig cadavers, the microneedles yielded great success while exhibiting no cytotoxicity or inflammatory effects.

Ultimately, the researchers were able to develop an optimized 3D printing process for polymeric microneedles, but assert that the technique could also be applied for other high-resolution microstructures.

Further details of the study can be found in the paper titled ‘Parametric optimization of two-photon direct laser writing process for manufacturing polymeric microneedles’.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows an example of a conventional microneedle patch. Photo via Georgia Tech.