Researchers from the Polytechnic University of Turin and the Hebrew University of Jerusalem have used 3D printing technology to enable a new level of performance in nano-electromechanical systems (NEMS).

The production of conventional semiconductor-based NEMS usually involves a highly complex, multi-step, and costly fabrication process. While alternative methods such as screen printing, hot embossing, micro-injection molding, and even 3D printing have been trialed, they’re usually limited to the micro range (MEMS) and deliver relatively low-quality factors.

Here, the joint research team leverages two-photon polymerization, a very precise form of SLA, to 3D print rigid NEMS resonators with performances comparable to those of silicon-based ones. By providing a viable, lower-cost alternative to semiconducting resonators, the work is expected to pave a new route to applications such as highly sensitive mass and force sensors.

An ever-miniaturized world

Since the start of the digital age, we’ve poured enormous amounts of resources into miniaturizing our electrical and electronic devices in a bid to make them lighter, more portable, and easier to store. This goes for consumer electronics such as smartphones, but it also goes for more industry-oriented systems such as sensing devices. In the case of the latter, miniaturization is also actually a direct component of performance.

Looking at high-performance mass and force detection, specifically, the lower limits of sensitivity in these types of sensors are determined by two factors: a tiny resonator mass and a high-quality factor ‘Q’.

The small mass allows for small perturbations to induce large resonance frequencies, while the high-quality factor Q means energy is retained for longer in the resonance mode, dampening the effects of smaller frequency fluctuations that would otherwise hide the true values of the larger perturbations. All in all, these two factors make for more precise sensors.

Two-photon polymerization for NEMS

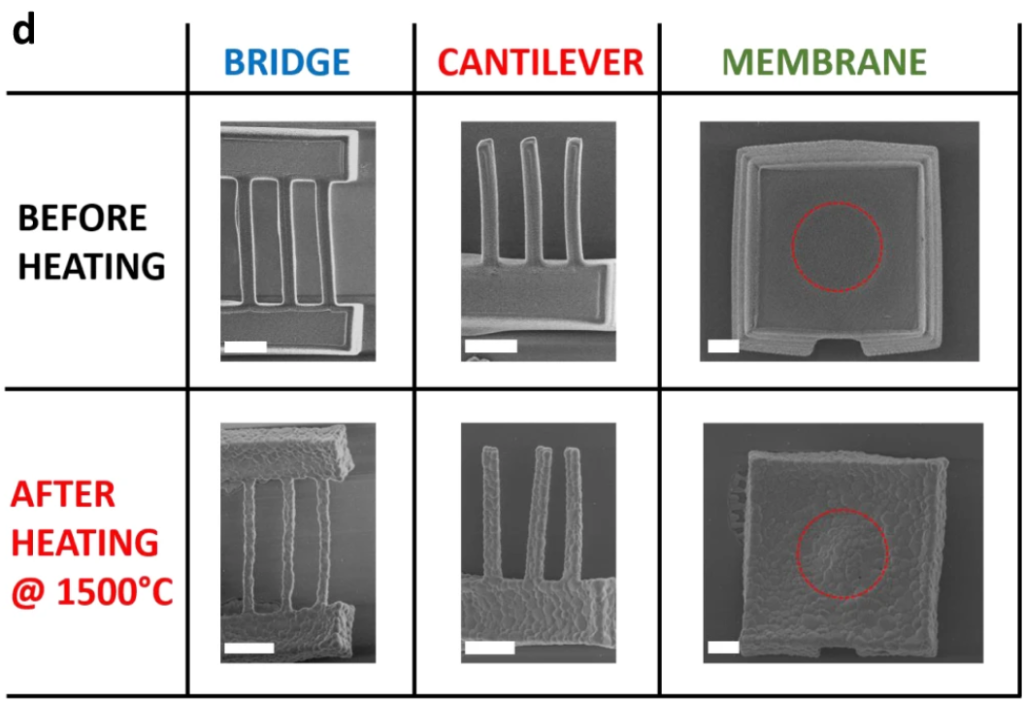

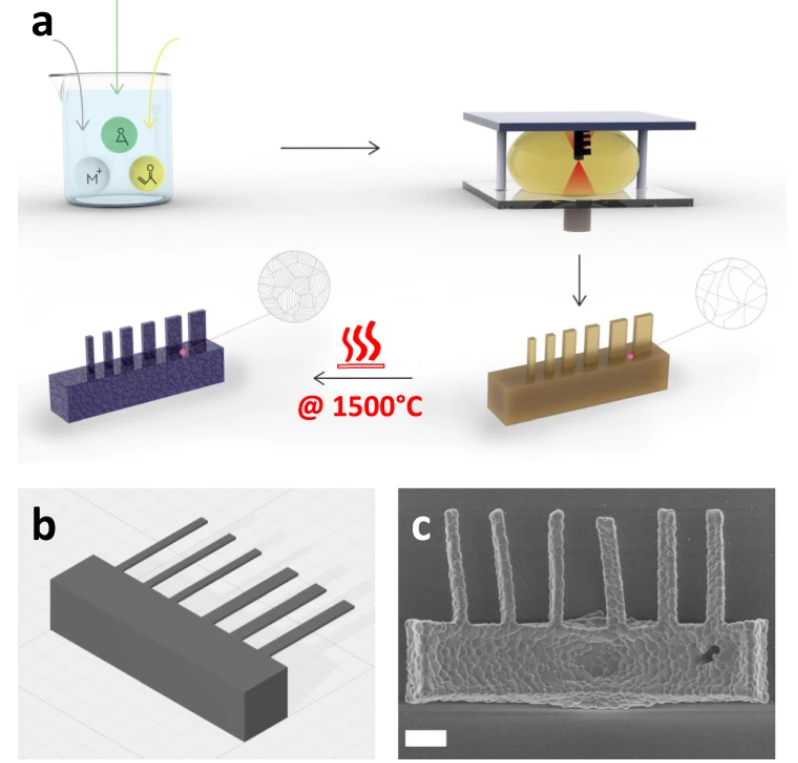

Unfortunately, achieving low masses and high Q in nano-scale sensing devices has historically required expensive and highly complex manufacturing approaches, which often also result in low fabrication yields. To challenge this, the research team employed the use of a Nanoscribe Photonic Professional GT 3D printer and a specially developed liquid ink made of metal salts.

After printing the NEMS resonator structures with the ink, the team heated the samples in a tube furnace for several hours to remove the organic content and increase the density of the metal precursors. This resulted in a set of rigid ceramic structures with high Young’s modulus and low damping characteristics.

The team reported that their 3D printed NEMS resonators delivered quality factors of up to 15,000 and tiny mass sensitivities of 450zg, which are indeed in line with the performances of conventional silicon-based NEMS resonators.

Further details of the study can be found in the paper titled ‘Reaching silicon-based NEMS performances with 3D printed nanomechanical resonators’.

The 3D printing of sensing components is an ever-growing application in the field of additive manufacturing. Last month, engineers at Washington State University (WSU) and DL ADV-Tech developed 3D printed sensors capable of detecting exposure to the herbicide glyphosate, which is thought to be carcinogenic. Integrated into a test kit, the 3D printed sensors are low-cost and don’t require special storage, making them an ideal tool for measuring exposure to harmful chemicals.

Elsewhere, researchers at Santa Clara University recently used 3D printing to build an upgraded version of the hydration sensing units deployed in agricultural irrigation systems. By redesigning and 3D printing parts of these sensors, the engineers were able to improve their thermal detection capabilities, as well as shrink their overall size.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Photonic Professional GT2 3D printer. Photo via Nanoscribe.