Researchers from the University of Toronto (UoT) and Sunnybrook Health Sciences Centre have developed a handheld device capable of 3D bioprinting sheets of skin that can heal burn wounds.

Described as a “handheld 3D printer”, the device deposits sheets of material formed by a bioink that covers the wound, helping to accelerate the skin’s healing process. It was designed as an in-situ solution to help accelerate the process of wound healing for patients with severe large-area burns.

3D printing your skincare routine

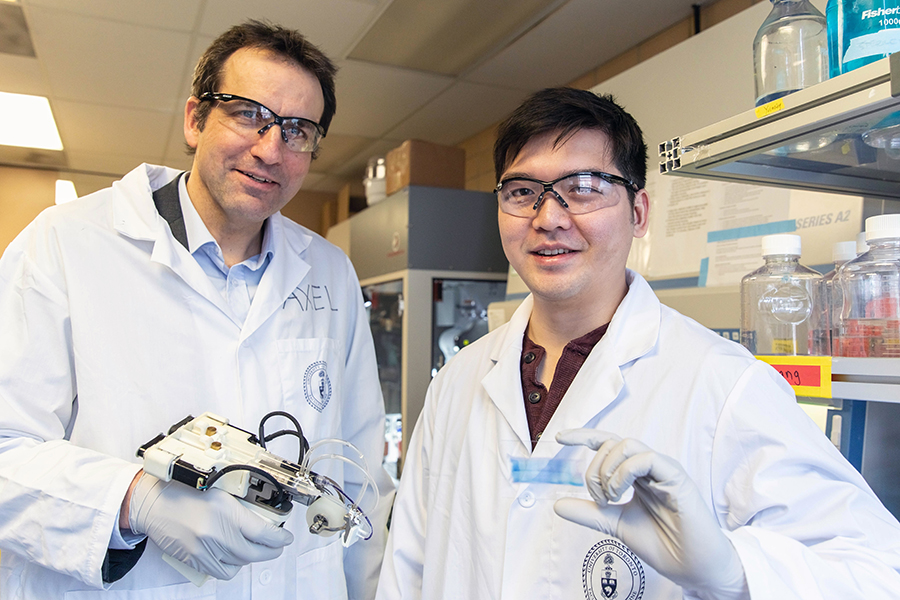

The project behind the handheld device is led by Richard Cheng (IBBME PhD candidate), under the supervision of Professor Axel Guenther (MIE), and in close collaboration with Dr. Marc Jeschke, director of the Ross Tilley Burn Centre, and his team at Sunnybrook Hospital.

According to the World Health Organization (WHO), an estimated 180,000 deaths in 2018 were caused by burns – the vast majority occurred in low-and-middle-income countries. The first prototype for the handheld 3D bioprinting device was first unveiled in 2018. “Most current 3D bioprinters are bulky, work at low speeds, are expensive and are incompatible with clinical application,” commented Dr. Axel Guenther at the time.

The difference between the prototype developed two years ago, and the updated device presented by the researchers in their paper, is demonstrable evidence that the deposited biomaterial can actually heal wounds: “Previously, we proved that we could deposit cells onto a burn, but there wasn’t any proof that there were any wound-healing benefits — now we’ve demonstrated that,” explains Guenther.

3D printing has played a key role in developing innovative solutions for medical skin treatments and wound care. For example, in 2018 scientists from the VTT Technical Centre of Finland, a state-owned research and development non-profit, developed a nanostructured cellulose 3D printable smart-dressing and 3D printed circuit board that heals and monitors skin wounds.

The handheld bioprinter

The researchers explain that the current method of care for burns – autologous skin grafting – is not effective when attempting to heal large, full-body burns. Autologous skin grafting, a method that transplants healthy skin from other parts of the body onto the wound, cannot provide enough healthy skin to heal full-thickness burns. These severe burns are characterized by the destruction of both the outermost and innermost layers of the skin, often covering a significant portion of the body.

In the paper, the researchers explain: “The current standard of care involves removal of damaged tissue from the wound, followed by application of an autologous skin graft with tissues obtained using a dermatome directly from the patient’s own skin. However, large-area burns often leave insufficient quantities of healthy skin for harvesting, precluding this application in cases of severe injury.”

The handheld 3D printer operates by using a roller to dispense a uniform sheet of biomaterial composed of a mesenchymal stroma cell (MSC) bioink. MSC’s are stem cells that differentiate into specialized cell types depending on their environment. As such, in this context, the MSC bioink promotes skin regeneration and reduces scarring.

To provide a solution to the limits of autologous skin grafting in treating large burn wounds, the researchers developed the handheld 3D bioprinter so that it could easily apply the biomaterial in a user-friendly manner: “The modular design of the handheld instrument grants the operator full control over the physical dimensions and material composition of the resulting skin precursor sheet,” the authors write.

Since the prototype in 2018, the handheld bioprinter has gone through 10 redesigns. The team aims to develop a final product that can be used by surgeons in an operating room. The current prototype includes a single-use microfluidic printhead to ensure sterilization and a soft wheel that follows the track of the printhead, allowing for better control for wider wounds.

Within the next five years, Jeschke believes the handheld skin printer could be seen in a clinical setting:

“Once it’s used in an operating room, I think this printer will be a game changer in saving lives. With a device like this, it could change the entirety of how we practice burn and trauma care.”

The paper, “Handheld instrument for wound-conformal delivery of skin precursor sheets improves healing in full-thickness burns,” is published in Biofabrication.

The nominations for the 2020 3D Printing Industry Awards are now open. Who do you think should make the shortlists for this year’s show? Have your say now.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.