A team of Japan-based researchers is investigating the use of selective laser melting (SLM) technology to 3D print single crystal structures made of pure nickel (Ni).

There’s been a growing demand for 3D printed Ni-based superalloys such as Inconel over the years. These high-temperature metals are often characterized by their excellent mechanical properties, corrosion resistance, and creep resistance, commonly operating in the 500°C+ temperature range. As such, they’re a go-to in the aerospace sector where they’re used to fabricate jet engine components like turbine blades.

Single crystal turbine blades are capable of operating at much higher temperatures than their crystalline counterparts, but the additive manufacturing of Ni-based single crystal superalloys has proven difficult thus far. While they can be processed via electron beam melting (EBM), the use of laser-based technologies like SLM usually requires the use of a single crystal seed (build plate).

Now, the team from Japan’s National Institute for Materials Science, Kyushu University, and Osaka University has used a flat-top laser profile to 3D print single crystal Ni without the need for a seed at all.

Difficulties in controlling grain formation

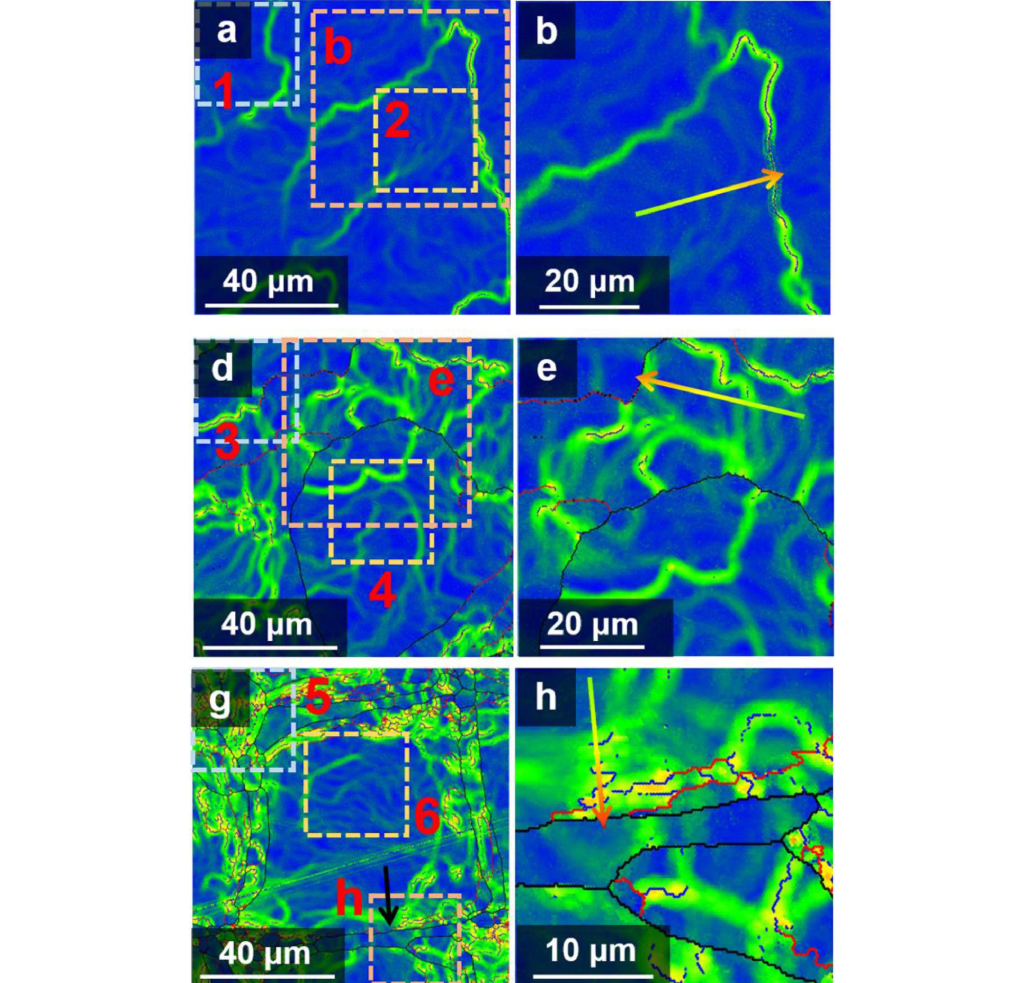

When printing with SLM, closely controlling the grain boundaries, strain suppression, and texture homogeneity of parts is a tricky process. This can be attributed to the steep thermal gradient inherent to the technology, whereby the top layer is rapidly heated, the layers underneath are cooler, and there’s limited heat conductivity in between. The repeated thermal cycles result in high strain and dislocation densities, leading to internal dynamic crystallization and the formation of new grains.

For more precise microstructural control, especially to obtain single crystals, users either need to fine-tune the scan strategy or use a single crystal seed from the get-go.

According to the researchers, Gaussian-based beam profiles are commonly used to control textures and microstructures in SLM, but there are currently no studies focused on flat-top beam profiles.

3D printing homogenous single crystal nickel

In the present study, the Japan-based team used an SLM Solutions SLM 280 HL system to produce pure Ni structures in an Ar environment. Firstly, polycrystalline Ni plates were used to examine the behavior of single flat-top laser tracks, which allowed the team to estimate the shape of the subsequent melt pools.

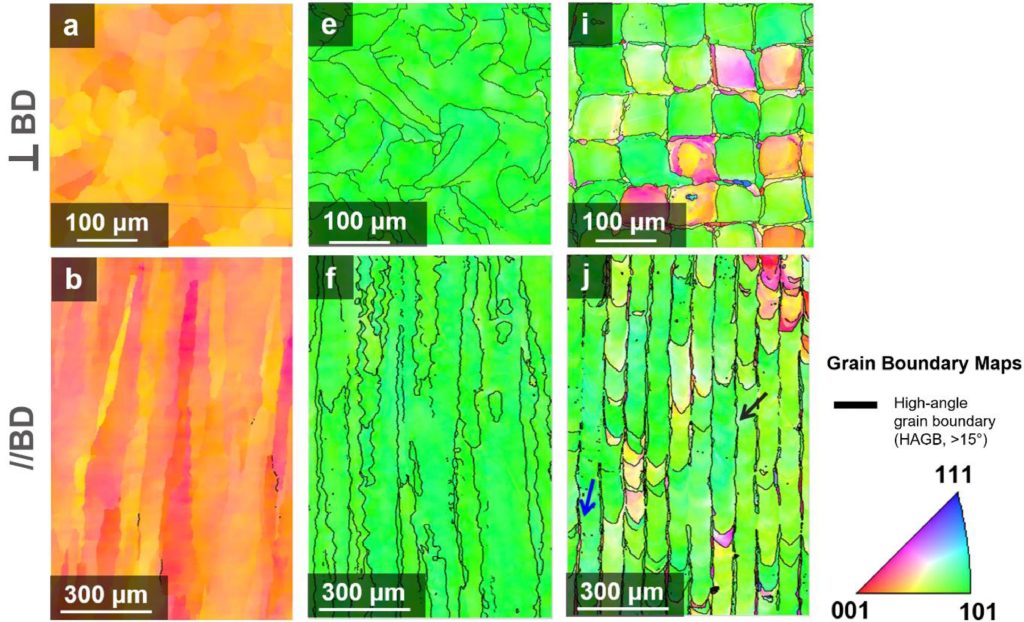

The melt pool depths were measured and the observed melt pool geometries were used to print cylindrical specimens made of Ni on polycrystalline stainless steel 304 build plates. Each of the specimens was ground and polished, and the microstructures were studied using scanning electron microscopy (SEM) imaging and electron backscatter diffraction (EBSD).

By optimizing the planar melt pool, the team was successful in 3D printing a homogenous single crystal structure made of pure Ni without relying on a single crystal build plate. The researchers state that the work provides novel insights into how various parameters can be used to control microstructure and its associated properties in the SLM process, particularly for ensuring single crystal structures. In future studies, the findings are set to be implemented with a wider range of metal alloys.

Further details of the study can be found in the paper titled ‘Manufacturing single crystals of pure nickel via selective laser melting with a flat-top laser beam’.

The world of metal additive manufacturing is rich and diverse in research. A team from Tsinghua University and the National University of Singapore recently investigated the effects of fluid flow on the mechanical properties of metal 3D printed parts. While factors such as temperature gradient and solidification velocity are well-studied, the effects of fluid flow in the melt pool of a 3D printed part hadn’t yet been investigated.

Elsewhere, a team of international researchers recently took a deeper dive into the fundamental physics behind metal 3D printing, all in the hopes of better understanding defects in printed parts. In critical industries where part performance is paramount, pores can pose a limitation on the types of parts that can be printed. As such, there’s an ongoing need to develop better defect detection and mitigation techniques in 3D printing.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows IPF maps and textures of flat-top-built 3D printed specimens. Image via Kyushu University.