A research team from King Abdullah University of Science and Technology (KAUST) in Saudi Arabia, has published a paper proposing 3D printed disposable and wireless sensors for monitoring large areas.

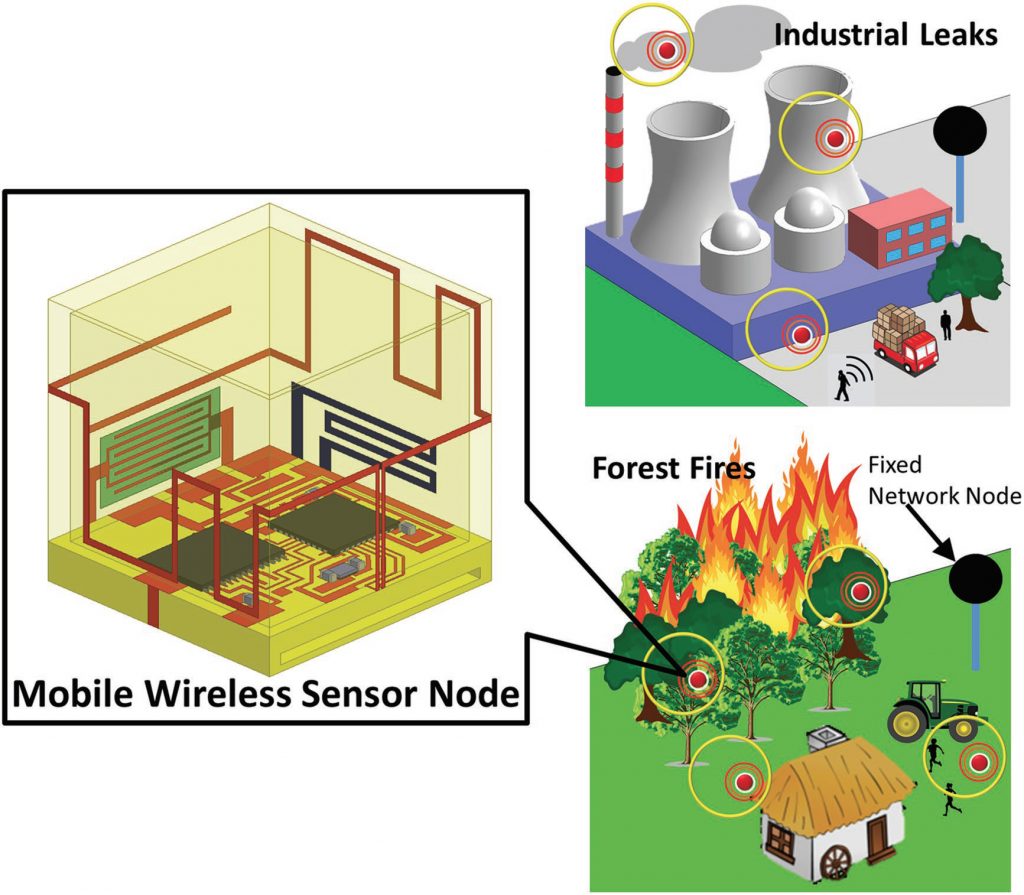

The proof-of-concept study shows the potential of 3D printing as a low-cost method of making fully integrated wireless sensors, which can be utilized in extreme environmental conditions such as forest fires and industrial leaks.

3D printed construction

The system proposed by researchers at KAUST relies on a central antenna, used as a receiver for a network of strategically placed sensors, i.e. inside cooling towers and chimneys, on trees and planted in the ground.

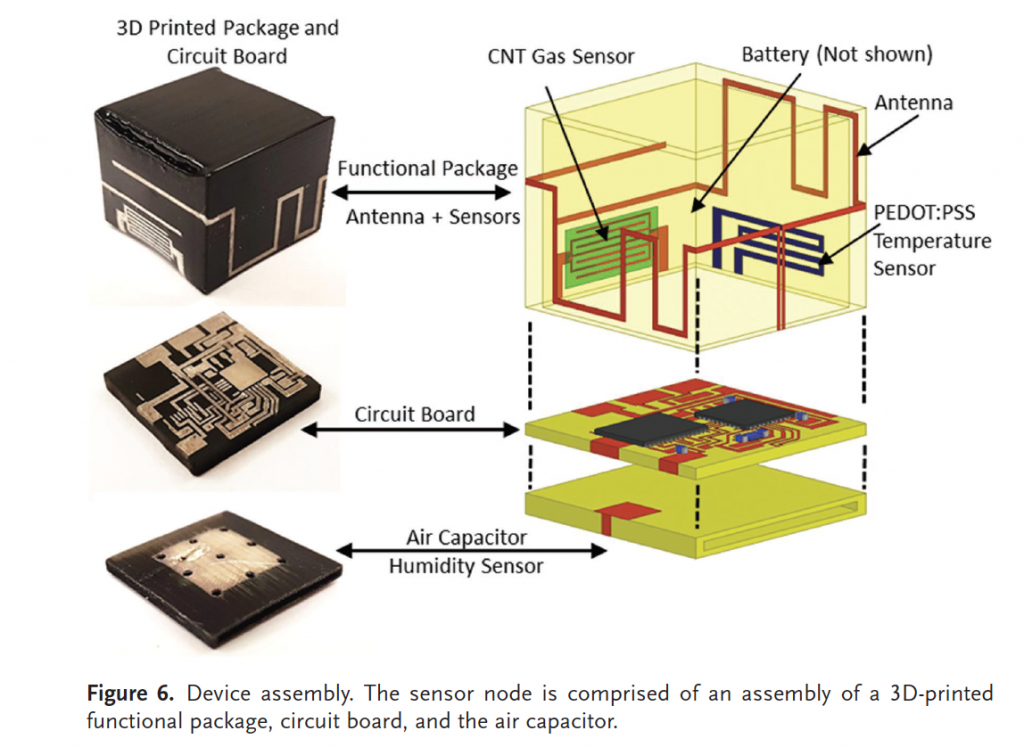

The disposable sensors, or nodes, themselves are composed of three different parts: an air capacitor, used to monitor humidity; circuit board; and a box/package complete with metallic strips for subsequent sensors and an antenna.

These three core parts were simultaneously 3D printed in rigid, opaque VeroBlackPlus material from Stratasys. 3D printing was performed on an Objet260 Connex1 3D printer, utilizing Stratasys’ PolyJet technology – where layers of jetted ink are cured into 3D parts using UV light.

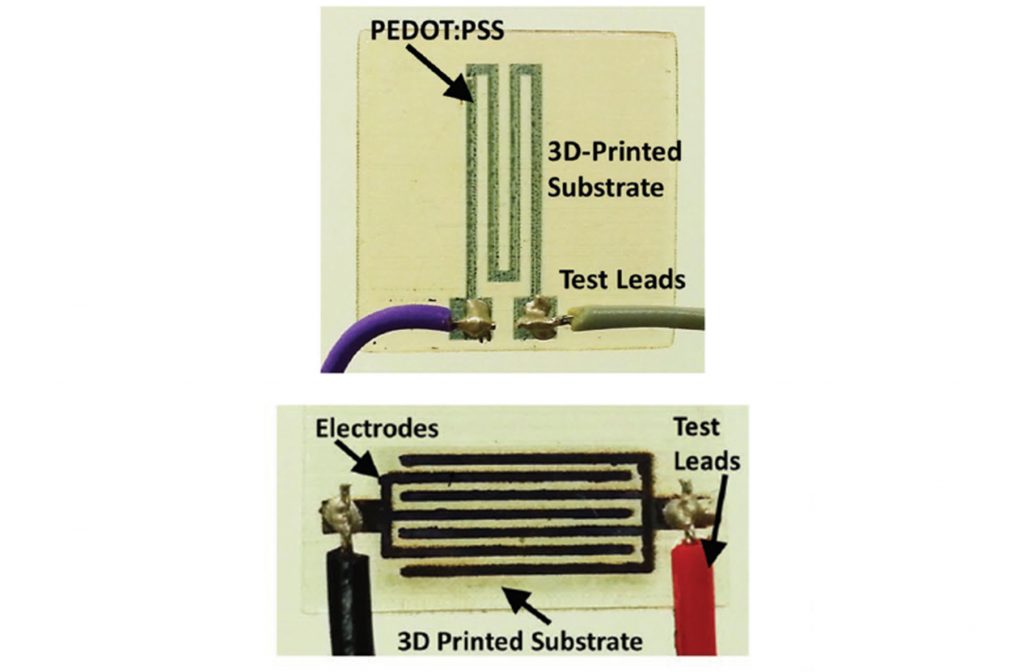

Metallic, electrically conductive strips, were then printed onto the walls of the package to make the sensors used to detect gas and temperature. They were 2D inkjet printed in a silver ink developed by the researchers in house.

The finished cube measures 21 mm x 21 mm x 21 mm, making it capable of fitting comfortably within narrow spaces.

An alternative to satellite observation?

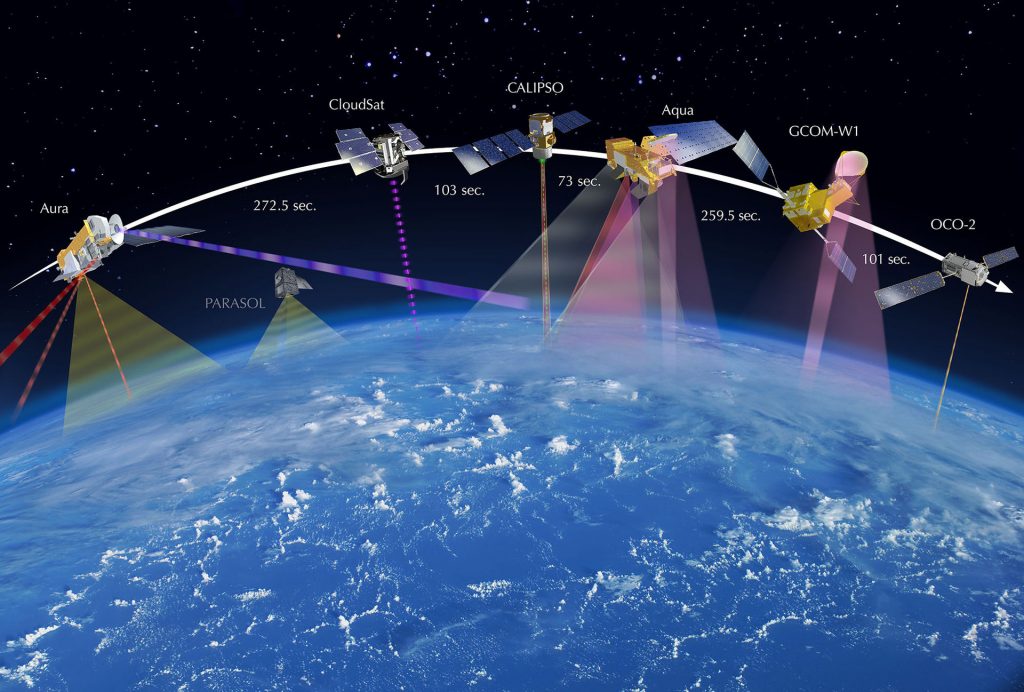

Satellite imaging is the existing alternative to in-situ sensors, but this method comes with two main disadvantages. Delivering information across such distances causes a delay in the informational response. Satellite observation also requires the permanent placement of satellites over a fixed spot, which is an impractical use.

By comparison, the KAUST sensors can theoretically be placed in any location, and tests show that they can “communicate readings of temperature, humidity, and H2S [hydrogen sulfide] levels up to a significant distance”, making the devices ideal for providing warnings in the case of wildfires and gas leaks. Drop tests were also performed, revealing that the devices were capable of operation even after a fall of 15 feet.

The researchers discuss further improvements to the devices as integrating the electronics into a single chip, and relying upon the improved availability of 3D printers capable of depositing metal and electric inks.

More in the area of 3D printed sensors

3D-Printed Disposable Wireless Sensors with Integrated Microelectronics for Large Area Environmental Monitoring is published online in the journal Advanced Materials Technologies, 19 May 2017. It is co-authored by Muhammad Fahad Farooqui, Muhammad Akram Karimi, Khaled Nabil Salama and Atif Shamim.

Two of the authors credited in this paper, Muhammad Fahad Farooqui and Atif Shamim, along with a third researcher, Christian Claudel, are previously credited in the development of similar sensors for flood detection.

3D printing has also been used by the McAlpine Research Group at the University of Minnesota, to make tiny sensors that could lead to the development of smart, wearable tech, and bionic skin.

For more of the latest 3D printing related research sign up to the 3D Printing Industry newsletter, like us on Facebook and follow us on Twitter.

Featured image: Researchers at King Abdullah University of Science and Technology, have used 3D Printed sensors to test for levels indicative of forest fires and industrial leaks. This photo is of a controlled fire by Sustainable Resource Alberta, started to promote diversity and create a wall to future fires. Photo by Cameron Strandberg, 38449766@N03 on Flickr