Relativity Space, a Californian aerospace startup, has signed a contract with the U.S. Air Force to operate its own launch facility on one of their sites.

The agreement permits the company to test its 3D printed rockets at the Cape Canaveral Air Force Station in Florida. The company plans the first launch of its Terran rocket at the end of 2020.

“We look forward to working with them as they continue the process to launch the Terran 1 vehicle from Cape Canaveral Air Force Station,” said Thomas Eye, the director of plans & programs for the 45th Space Wing of the U.S. Air Force.

“We were impressed with Relativity’s seasoned team and its innovative approach to space technology.”

The rapid growth of Relatively Space

Cape Canaveral has been used for launches from SpaceX, United Launch Alliance and Blue Origin. Relativity Space is the newest of these companies to use the launch station. In fact, the company was established because the founders, Tim Ellis and Jordan Noone, both worked at Blue Origin and SpaceX, and felt that neither company had seen the true potential of 3D printing for rocket manufacturing.

Aerojet Rocketdyne was the first company to manufacture and successfully test an engine that was entirely 3D printed, in 2014. However, to date, there are no 100% 3D printed rockets. Relativity Space is currently building a mid-size orbital rocket with 95% 3D printed parts.

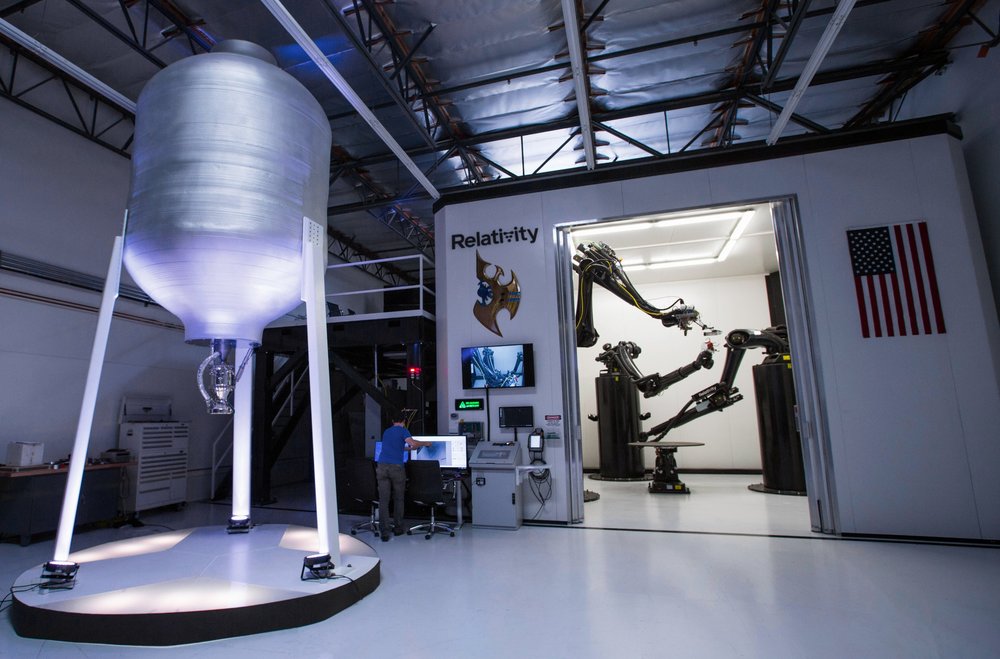

Soon after its inception, Relativity Space grew rapidly, raising $45.1 million in three years. It has recently closed $140 million in Series E funding, and built one of the world’s largest 3D printers – Stargate – standing at 7 feet wide and 14 feet tall. One of the company’s goals for 2020 is to 3D print a 90-foot-tall, 7-foot-wide rocket, using the Stargate.

3D printed rocket engines

While SpaceX has been using 3D printed components for four years, most notably in its Superdraco engine, it has not yet moved into building entire rockets or rocket engines this way. However, it is beginning to use more additive manufacturing materials for other projects. Recently, SpaceX produced a 3D printed satellite with Telesat, a Canadian satellite communications company.

Blue Origin’s reusable rocket, New Shepard, was built with “over 400 additively manufactured parts,” according to its President, Rob Meyerson, who made a bid to use 3D printed components increasingly in the future. Lately, the company has been working on selling tickets for commercial space flights in 2019, and is currently developing reusable rockets with 3D printed components and materials.

One company that has produced a full rocket engine using 3D printing techniques is Launcher, founded in 2017. The New-York based company specialises in 3D printed engines (not necessarily for rockets), and last October, used its techniques to develop a liquid oxygen (LOX)/kerosene rocket, which can transport satellites into low orbit around Earth.

The Terran rocket is estimated to cost $10 million per launch, but Relativity Space anticipate that it will save money by using the Cape Canaveral launch pad – it would take about four years to build Relativity’s own launchpad from scratch, Ellis estimated.

Did you know, you can nominate your favorite aerospace company for the 3D Printing Industry Awards 2019? There are all sorts of categories to reward the best players of the year.

You won’t want to miss the latest 3D printing news. Keep up by subscribing to our newsletter, or follow us on Twitter and like us on Facebook.

We know where the best jobs in the industry are. Go to 3D Printing Jobs to get started additive manufacturing.

Featured image shows a computer rendering of Relativity Space’s Terran rocket launching from Cape Canaveral’s LC-16 launchpad. Image via Relativity Space.