3D printing rocket manufacturer Relativity Space has raised $650 million in Series E funding to ramp up the production of its new Terran R rocket, the company’s first reusable, fully 3D printed launch vehicle.

The company announced its plans for the Terran R alongside the outcome of its Series E equity round, and will seek to scale up the production of the rocket with the funds raised. The launch vehicle will eventually offer customers a “point-to-point space freighter” capable of carrying out missions between the Earth, Moon, and even Mars.

The Terran R will also be a direct challenger to Elon Musk’s SpaceX Falcon 9 rocket and the recently announced 3D printed reusable Neutron launch vehicle from fellow aerospace firm Rocket Lab.

“From our founding days in Y Combinator just five years ago, we planned on 3D printing Terran 1 and then Terran R – a 20x larger fully reusable rocket – on our Factory of the Future platform,” said Tim Ellis, CEO and Co-founder of Relativity Space. “Today, we are one step closer to this goal.

“Together with our first rocket Terran 1, our second product, Terran R, will continue to take advantage of Relativity’s disruptive approach to 3D printing – reduced part count, improved speed of innovation, flexibility and reliability – to bring to market the next generation of launch vehicles.”

How Relativity Space is taking flight

Since entering the private space exploration market in 2015, Relativity Space has been developing its first 3D printed rocket, the Terran 1, in-house using its Stargate 3D printer. Having raised $500 million worth of investment in 2020, investor confidence appears high ahead of the rocket’s inaugural launch later this year.

In 2019, the firm was given the go ahead to build a 220,000 square foot rocket building factory at NASA’s Stennis Space Center and last year moved to a new Californian HQ to ramp up its production.

Over the last few years, Relativity Space has earned a number of high-profile contracts from the likes of satellite producers Iridium Communications and Telesat to fire their small satellites into Low Earth Orbit (LEO). The firm’s Terran 1 has also been selected by defense contractor Lockheed Martin for an upcoming cryogenic testing mission by NASA, and at the beginning of the year was awarded a $3 million NASA contract to launch multiple small satellites into LEO.

Most recently, Relativity Space landed its first orbital launch contract from the US Department of Defense (DoD) to launch a payload into LEO using its Terran 1 rocket, the aim being to open up low-cost, responsive access to space “as a service”.

“Relativity was founded with the mission to 3D print entire rockets and build humanity’s industrial base on Mars,” said Ellis. “We were inspired to make this vision a reality, and believe there needs to be dozens to hundreds of companies working to build humanity’s multiplanetary future on Mars. Scalable, autonomous 3D printing is inevitably required to thrive on Mars, and Terran R is the second product step in a long-term journey Relativity is planning ahead.”

A $650 million boost

To drive forward its long-term goals, Relativity Space has secured $650 million in Series E funding, led by investment firm Fidelity Management and Research Company.

The round also saw participation from other investors including Baillie Gifford, BlackRock, Centricus, Coatue, K5 Global, Soroban Capital, Tiger Global, Tribe Capital, and XN, among others.

Additionally, well-known names such as Marvell Director Brad Buss, entrepreneur and billionaire Mark Cuban, US actor Jared Leto, and US entrepreneur Spencer Rascoff also invested in the funding round.

The funds raised will be used to ramp up production of its Terran R launch vehicle, which is scheduled to launch in 2024 from Relativity Space’s site at Cape Canaveral, the same site from which the firm’s Terran 1 will launch later this year.

The Terran R

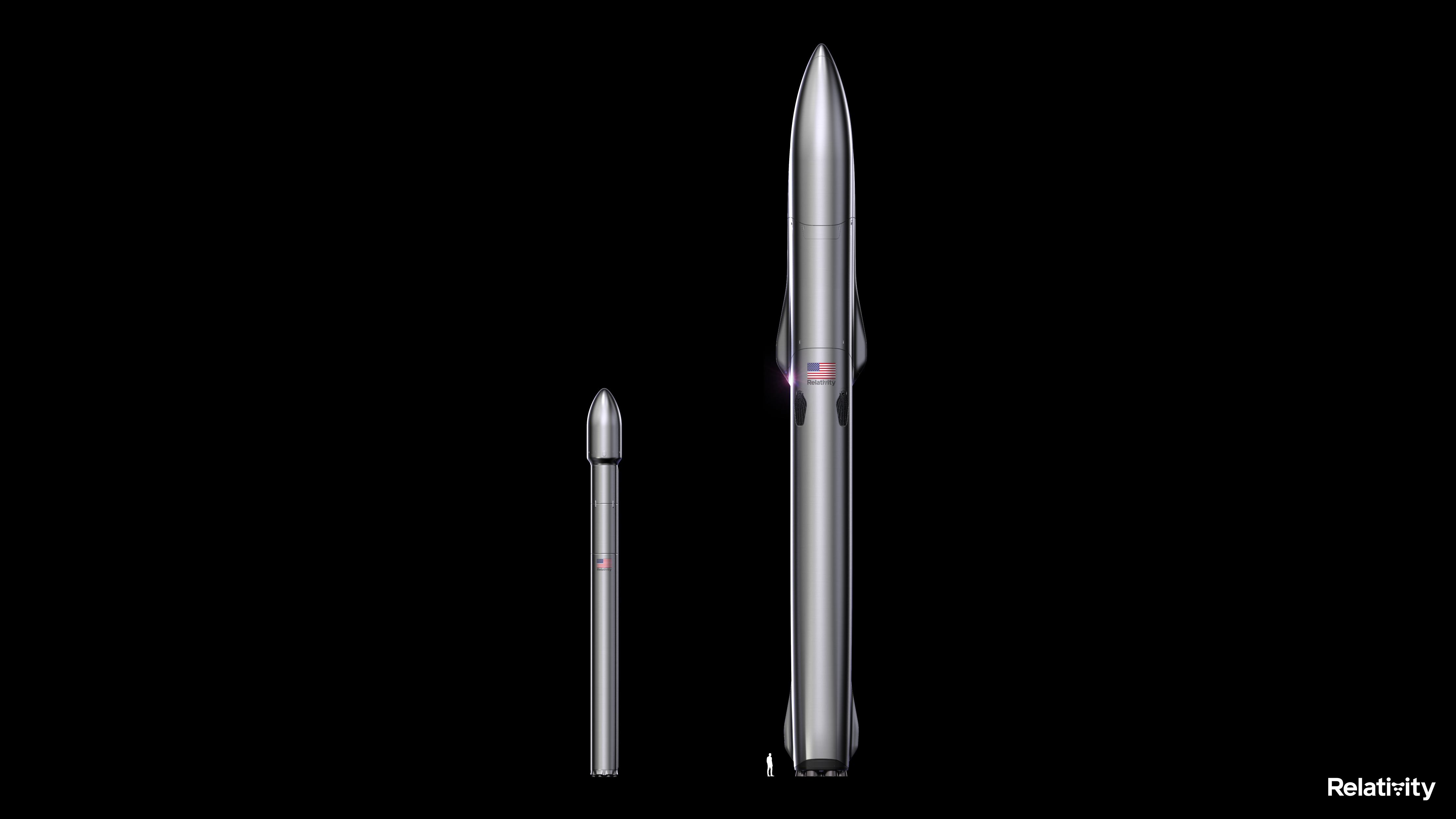

The Terran R is a two-stage, 216-foot tall rocket with a 16-foot diameter and five-meter payload fairing. The rocket is designed to be fully reusable including its engines, first stage, second stage, and payload fairing, and will be capable of launching over 20,000kg to LEO.

The Terran R will be fitted with seven entirely 3D printed Aeon R rocket engines delivering 302,000 lb of thrust each, while its upper stage will house one Aeon Vac engine. The Aeon R engine is a scaled, high pressure version of the gas generator cycle Aeon 1 due to fly on the firm’s Terran 1 rocket. The engine uses cryogenic liquid methane and oxygen propellants and runs with autogenous tank pressurization.

Once built, the Terran R will be capable of launching 20 times more payload than the Terran 1. The rocket is designed to provide both commercial and government customers more affordable access to space, LEO, and beyond to the Moon and Mars.

“Terran R is at the cutting edge of rocket innovation and design,” said Zach Dunn, SVP of Engineering and Manufacturing at Relativity. “Fully reusable and entirely 3D printed, Terran R will be well suited to serve customers’ evolving needs in the large satellite constellation industry, while also representing a significant leap towards achieving our mission of building humanity’s industrial base off Earth.”

Relativity Space has already signed its first anchor customer launch contract for the Terran R, adding to the company’s growing pipeline of commercial interest.

“There’s an organic relationship between 3D printing and reusability, and it gives us an unparalleled advantage to design the best fully reusable rocket possible,” added Ellis. “Over the last year, we found ourselves being asked by the market to accelerate development of our larger launch vehicle, so we knew it was time to double down on our existing plans and scale the Terran R program even faster and build production capabilities at scale sooner.”

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews and webinar replays.

Featured image shows render of the reusable, fully 3D printed Terran R rocket. Image via Relativity Space.