America’s most prominent 3D printing event, RAPID + TCT, kicked off this week in Detroit with more than 400 exhibitors showcasing their product and service offerings on the trade show floor.

3D Printing Industry is reporting live from the event all week, and you can take a first glance at all the RAPID + TCT 2022 news here. This round-up looks at new materials launched during the event so far, featuring updates from Formlabs, Uniformity Labs, Jabil, Trumpf, Morf3D, 6K Additive, and more.

Formlabs announces new PU resins

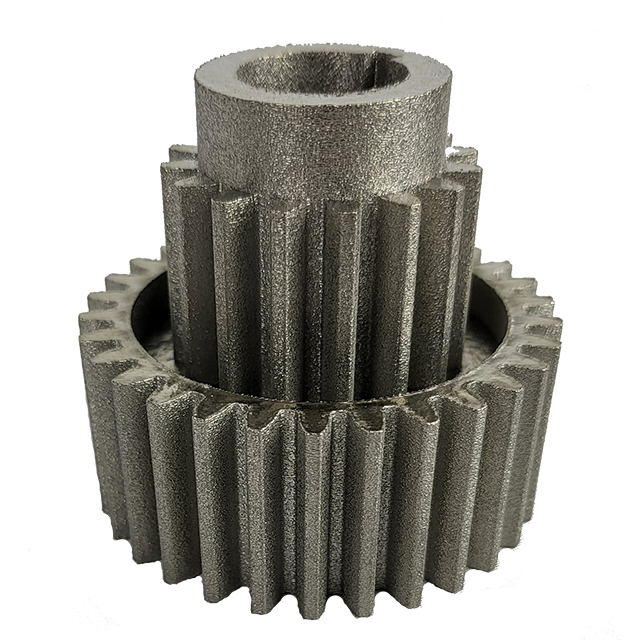

Kickstarting the material launches at RAPID + TCT 2022 is resin-based 3D printer manufacturer Formlabs, which has added two new polyurethane (PU) resins to its engineering resin portfolio. Designed for the production of rigid and durable parts, PU Rigid 650 Resin and PU Rigid 1000 Resin are available for use on the firm’s Form 2, Form 3, Form 3+, Form 3B and Form 3B+ SLA systems, and are reportedly the toughest materials in its SLA resin library.

PU Rigid 650 Resin is engineered to produce impact-resistant and pliable parts capable of maintaining their dimensional accuracy under load, such as high-performance connectors, wheels, and bumpers for the automotive and aerospace sectors. Meanwhile, PU Rigid 1000 Resin can be used to produce semi-stiff, sturdy and unyielding parts that can repeatedly endure high-stress environments, such as jigs and fixtures, castings, and enclosures.

“We’re thrilled to debut these innovative polyurethane resins as we continue to expand our materials library and unlock new possibilities with 3D printing,” said Dávid Lakatos, Chief Product Officer at Formlabs. “PU Rigid 650 Resin and PU Rigid 1000 Resin build upon the existing capabilities of Formlabs’ SLA printers to provide manufacturers, engineers, and product designers with the ability to produce polyurethane parts that can withstand extreme manufacturing environments and design requirements.”

Formlabs’ new PU Rigid 650 Resin and PU Rigid 1000 Resin are on display at the firm’s booth (2608) at RAPID + TCT 2022.

Morf3D and 6K qualify metal powders for AM

Meanwhile, specialty 3D printing material developer 6K and metal 3D printing service bureau Morf3D have announced a partnership to qualify 6K’s metal powders for additive manufacturing use by Morf3D’s aerospace and defense customers.

The latter will use 6K’s sustainably sourced powders, upcycled through the firm’s patented UniMelt technology, to react quickly to customer needs once qualification is complete.

“By working with Morf3D, we’re able to leverage their deep industry experience and application expertise to help guide the qualification process,” said Frank Roberts, President of 6K Additive. “This is a conduit to acceptance by a demanding customer base in space, aviation, defense industries, and more.

“We want our powders to be part of manufacturing solutions for the most intense applications in additive manufacturing and partnering with Morf3D provides us with another channel to these important customers.”

Uniformity Labs launches new titanium alloy for LPBF

Also at RAPID + TCT 2022, additive manufacturing materials developer Uniformity Labs has unveiled a new Ti-6Al-4V Grade 23 titanium alloy powder for LPBF 3D printing. Designed to deliver “best-in-class” mechanical performance, surface roughness, and uniformity across the build bed, Ti64 Grade 23 is reportedly capable of producing 3D printed builds with an average 99.96% density between 1.5-2 times quicker than previously possible, depending on machine and part geometry.

The availability of the new powder follows the company’s recent partnership with French industrial 3D printer manufacturer AddUp to optimize its Ti64 Grade 23 ELI alloy using the latter’s FormUp350 LPBF printer. In particular, the firms are targeting 3D printed applications within the regulated healthcare and aerospace sectors.

“The application of Uniformity Ti64 Grade 23 delivers material properties excellence and repeatability for our customers who require parts that perform to the highest standard in extreme conditions,” said Uniformity Labs Founder and CEO, Adam Hopkins. “Our powders deliver robust mechanical properties, low surface roughness, and high print yield, in addition to substantially increasing machine throughput.”

Jabil unveils patent-pending polyketone PBF powder

Also on display at RAPID + TCT 2022 is global manufacturing specialist Jabil’s new patent-pending polyketone (PK) 5000 3D printing powder for powder-based platforms. PK 5000 has been engineered to provide greater strength, chemical resistance, and resilience in comparison to general-purpose nylon materials like PA12, and is designed to support highly-demanding applications within the automotive, consumer products, defense, and healthcare industries.

The likes of EOS, Farsoon, and 3D Systems are currently evaluating the material for their 3D printing systems, and Jabil is developing process parameters for all major SLS platforms to ensure widespread access to the material. Jabil is showcasing PK 5000 at its RAPID + TCT booth (1541), alongside its 3D printing services.

TRUMPF qualifies Equispheres’ AlSi10Mg for TruPrint 3000

Rounding off the new materials updates announced thus far at RAPID + TCT 2022 is German machine tool manufacturer TRUMPF, which has qualified aluminum powders from Canadian 3D printing powder producer Equispheres for its TruPrint 3000 series of 3D printers.

The qualification process established that Equispheres’ AlSi10Mg powders are capable of achieving up to a 33% faster throughput than standard aluminum powder with a ‘productivity’ parameter set, and a 13% faster build rate with TRUMPF’s standard parameter set. The two parameter sets are to be released with the firm’s TruPrint 3000 3D printing systems to enable its customers to achieve higher productivity levels.

“We are very pleased that TRUMPF has quantified the improved performance that results from the pairing of its advanced additive manufacturing equipment and our unique powder,” said Evan Butler-Jones, Vice-President – Product & Strategy for Equispheres. “This combination will offer TruPrint users significant productivity increases.

“This work confirms that our powders contribute to substantially better build rates when used on modern, high-quality additive manufacturing systems.”

3D Printing Industry will continue to bring you all the news, updates, and launches from RAPID + TCT 2022 over the course of the show, so be sure to check back regularly to keep up with the latest developments.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Subscribe to our YouTube channel for the latest 3D printing video shorts, reviews, and webinar replays.

Featured image shows a selection of parts 3D printed with Formlabs’ PU Rigid 650 Resin. Photo via Formlabs.