3D Printing Industry has been taking a closer look at the 2019 formnext start-up challenge.

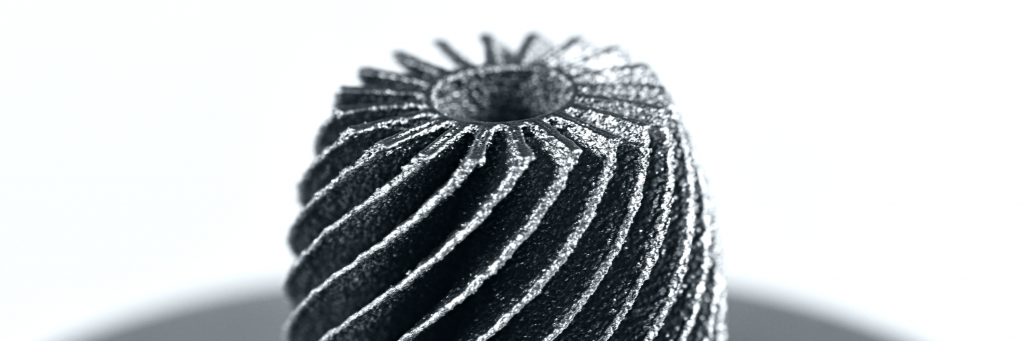

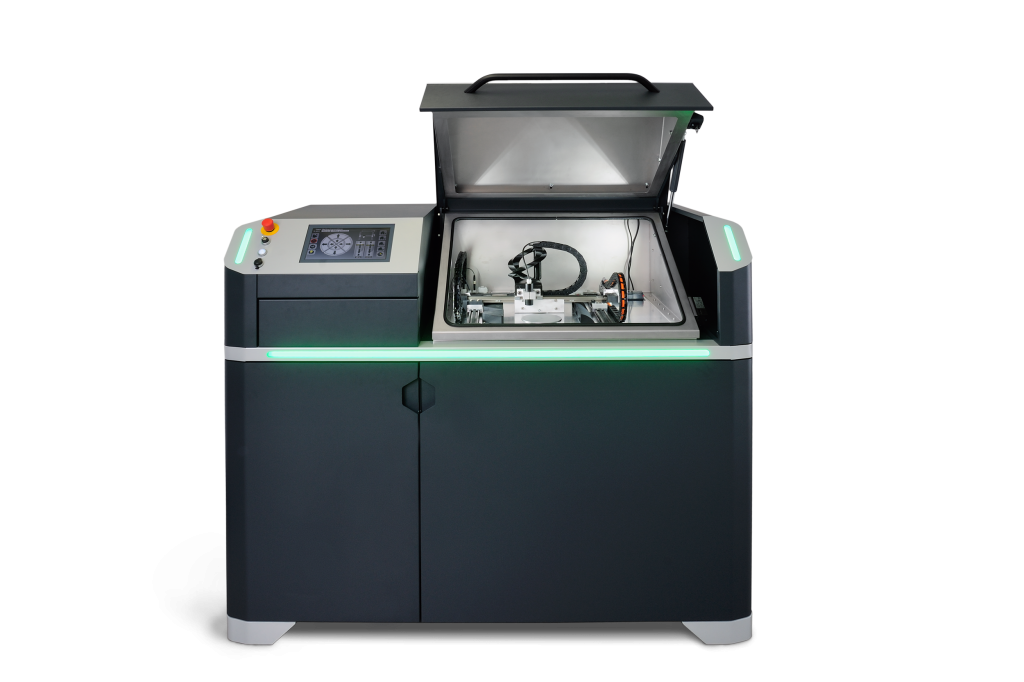

The final winner of this year’s competition is Laser Melting Innovations. The first metal additive manufacturing system developed by the company is the Alpha 140, a laser-based system capable of working with stainless steels, aluminum, plus nickel-chromium and cobalt-chromium alloys.

3D Printing Industry: When was your company founded and where are operations based?

LMI: LMI was founded mid 2017 as a spin-off of the Fraunhofer ILT headquartered in Aachen, Germany.

3D Printing Industry: What does your company do?

LMI: We develop and market machines for the additive manufacturing of metal components.

3D Printing Industry: How does your company fit into the additive manufacturing ecosystem?

LMI: Our goal is to democratize metal additive manufacturing. Therefore, we developed a machine that completely adjusts to the needs of companies who want to enter this technology.

We want to overcome existing barriers for the implementation of additive manufacturing processes and address especially inexperienced users.

3D Printing Industry: What were you hoping to gain from exhibiting at Formnext 2019?

LMI: Formnext is one of our most important communication instruments to spread our vision. At the trade fair, our customers can experience the machine in action and convince themselves of the outstanding part quality. In addition, the Formnext enables us to make direct contact with users from our various target groups and to establish new valuable relationships.

3D Printing Industry: How would you describe the roadmap for your enterprise in the coming years?

LMI: Additive manufacturing is a key technology. It affects all sizes of companies, everywhere. Companies that ignore this technology won’t be able to stay competitive in the mid-term.

We want to provide companies with the right tools to make additive manufacturing easier and more approachable in order to offer our customers a decisive competitive advantage and unlock the full potential of metal AM!

3D Printing Industry: Is there anything else you would like our readers to know about?

LMI: We are a young and ambitious company, which takes the interests of its customers very seriously. Our scientific background enables the integration of the latest technologies into our machine development.

More information about Laser Melting Innovations is available online.

For more additive manufacturing news, follow our social media accounts on Twitter, Facebook, and LinkedIn.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.